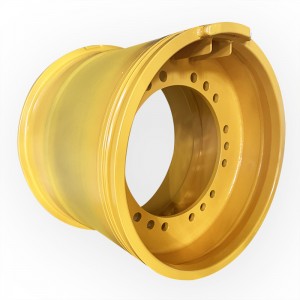

15.00-25/3.0 rim for Port Machinery Universal

Road Crane:

Port machinery is the core equipment of modern port logistics system, mainly used for loading, unloading, handling, stacking and short-distance transportation of goods. The following are the main uses of port machinery and their specific application scenarios:

1. Container loading and unloading

- Purpose: Loading, unloading and transshipping containers is one of the main tasks of port machinery, suitable for the connection of sea, rail and road transportation.

- Equipment:

- Shore crane (STS crane): lift containers from ships to docks or load them from docks to ships.

- Rubber-tyred gantry crane (RTG)/rail-mounted gantry crane (RMG): lift and stack containers in the yard.

- Reach stacker: flexibly transfer and stack containers in the yard.

- Terminal tractor: transport containers to the yard or loading and unloading point over short distances.

2. Bulk cargo loading and unloading

- Purpose: Loading and unloading bulk cargo such as coal, ore, grain, cement, etc., and achieve efficient handling through conveying devices or grabs.

- Equipment:

- Bucket wheel stacker and reclaimer: used for stacking and reclaiming bulk cargo.

- Ship loader: transports bulk cargo from the stockpile to the ship.

- Ship unloader: unloads bulk cargo from the ship and transports it to the stockpile or conveying system.

- Grab crane: suitable for loading and unloading of bulk cargo such as coal and ore.

3. Liquid cargo loading and unloading

- Purpose: handles the loading and unloading of liquid cargo (such as crude oil, chemicals, liquefied natural gas, etc.).

- Equipment:

- Liquid loading and unloading arm: transports liquid cargo from the ship to the shore tank, or vice versa.

- Liquid pump system: provides transportation power for liquid cargo in the port pipeline.

4. Vehicle and roll-on/roll-off cargo loading and unloading

- Purpose: specially used for transporting roll-on/roll-off cargo such as cars, trucks, engineering equipment, etc.

- Equipment:

- Roll-on/roll-off ramp system (Ro-Ro): connects the ship and the terminal for vehicle boarding and disembarking operations.

- Dump truck loading and unloading equipment: handles loading and unloading tasks of trucks and other vehicles.

5. Short-distance transportation and sorting

- Purpose: transfer goods within the port area (such as transportation from the terminal to the yard), and sort them according to the type and destination of goods.

- Equipment:

- Automated Guided Vehicle (AGV): unmanned vehicle used for cargo transfer in automated terminals.

- Forklift: stacks and classifies goods in the yard.

- Belt conveyor system: suitable for short-distance transmission of bulk goods.

6. Terminal maintenance and support

- Purpose: provides terminal infrastructure maintenance, ship repair and other auxiliary operations.

- Equipment:

- Floating crane: used for water engineering and terminal maintenance.

- Lift forklift: used for handling equipment, materials and small goods.

7. Special cargo handling

- Purpose: handles special cargo that is overlong, overwide or overweight, such as wind power equipment, large machinery, pipelines, etc.

- Equipment:

- Heavy cranes: such as floating cranes and portal cranes, used for loading and unloading large or overweight cargo.

- Special grippers and clamps: customized according to the shape of the cargo, such as steel coil clamps, wood grippers, etc.

8. Comprehensive logistics support

- Purpose: Play a role in port warehousing, distribution and logistics services, including the storage, stacking and distribution of goods.

- Equipment:

- Forklifts: used for loading, unloading and stacking of small cargo and pallet cargo.

- Pallet trucks: suitable for cargo handling in warehouses or distribution centers.

Port machinery is widely used in the loading, unloading and transshipment of various types of cargo such as containers, bulk cargo, liquid cargo, roll-on/roll-off cargo, etc., and is a key facility for modern ports to achieve efficient operations and improve logistics efficiency.

Production Process

1. Billet

4. Finished Product Assembly

2. Hot Rolling

5. Painting

3. Accessories Production

6. Finished Product

Product Inspection

Dial indicator to detect product runout

External micrometer to detect internal micrometer to detect the inner diameter of the center hole

Colorimeter to detect paint color difference

Outside diametermicromete to detect position

Paint film thickness meter to detect paint thickness

Non-destructive testing of product weld quality

Company Strength

Hongyuan Wheel Group(HYWG) was founded in 1996,it is professional manufacturer of rim for all kinds of off-the-road machinery and rim components,such as construction equipment, mining machinery, forklifts,industrial vehicles,agricultural machinery.

HYWG has advanced welding production technology for construction machinery wheels at home and abroad, an engineering wheel coating production line with the international advanced level, and an annual design and production capacity of 300,000 sets,and has a provincial-level wheel experiment center, equipped with various inspection and testing instruments and equipment, which provides a reliable guarantee for ensuring product quality.

Today it has more than 100 milion USD assets,1100 employees,4 manufacturing centers.Our business covers more than 20 countries and regions around the world, and the quality of all products has been recognized by Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD and other global oems.

HYWG will continue to develop and innovate, and continue to serve the customers wholeheartedly to create a brilliant future.

Why Choose Us

Our products include the wheels of all off-road vehicles and their upstream accessories, covering many fields, such as mining, construction machinery, agriculture industrial vehicles, forklifts, etc.

The quality of all products has been recognized by Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD and other global oems.

We have a R&D team composed of senior engineers and technical experts,focusing on the research and application of innovative technologies, and maintaining a leading position in the industry.

We have established a perfect after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure a smooth experience for customers during use.

Certificates

Volvo Certificates

John Deere Supplier Certificates

CAT 6-Sigma Certificates