October 30-November 2, 2024 The Korea International Agricultural Machinery and Technology Exhibition (KIEMSTA 2024) is one of the important agricultural machinery and technology display platforms in Asia. It is Korea's leading international agricultural machinery, equipment and technology exhibition, held every two years in autumn. Highlights of the exhibition include innovations and trends, showcasing contributions from many companies around the world. It highlights the challenges and opportunities of entering the Korean market, especially for German manufacturers, as Korea's economic significance grows. The exhibition focuses on the latest agricultural machinery, equipment, technology and innovation, aims to promote the development of the agricultural industry and provide a platform for communication and cooperation.

The exhibits displayed at the exhibition include the following:

1. Agricultural machinery: tractors, harvesters, rice transplanters, seeders and other types of agricultural machinery.

2. Engineering and agricultural vehicles: such as agricultural trucks, four-wheel drive vehicles, field management vehicles, etc.

3. Facilities and equipment: agricultural irrigation systems, storage equipment, processing equipment, greenhouse equipment

4. Smart Agriculture and Technology: Internet of Things technology, smart agricultural management system, drone applications, sensors, etc.

5. Environmental protection and new energy: environmental protection technology, new energy agricultural machinery and equipment, sustainable agricultural solutions, etc.

In this exhibition, many well-known manufacturers will release their latest products and technologies and demonstrate the application of their machinery and equipment in actual operations to improve visitors' understanding. The organizer will also provide a variety of business negotiation and docking services to promote international cooperation. There will also be many industry experts sharing the latest industry trends, technology applications and future development directions.

KIEMSTA has attracted many professional visitors and exhibitors from all over the world. It is a high-quality platform for displaying products and technologies, and also provides a good opportunity for companies to explore the Asian market.

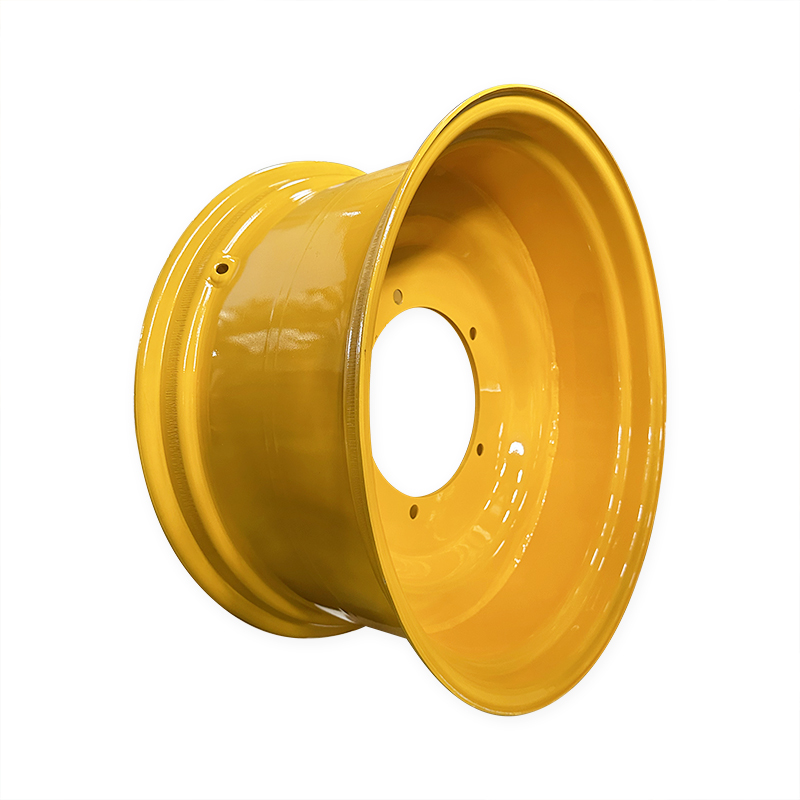

As China's No. 1 off-road wheel designer and manufacturer, and also the world's leading expert in rim component design and manufacturing, we were invited to participate in this exhibition and brought several rim products of different specifications.

The first one is a 14x28 one-piece rim used on JCB industrial vehicle telescopic forklifts. The corresponding tire of the 14x28 rim is 480/70R28. 14x28 is widely used in engineering vehicles such as backhoe loaders and telescopic forklifts.

This rim has the following features when used on JCB telescopic forklifts:

1. Durability and reliability: Telescopic forklifts are usually used for material handling and aerial work in harsh environments such as construction sites, so the rim needs to be durable and reliable enough to cope with various complex working environments and conditions.

2. Carrying capacity: The rim needs to be able to withstand the weight of the telescopic forklift itself and the additional load during lifting or handling, so it needs to have a high carrying capacity.

3. Stability: For aerial work equipment such as telescopic forklifts, stability is crucial. Therefore, this rim may be designed to provide good stability and balance to ensure a safe aerial work environment.

4. Adaptability: This rim may be designed to adapt to different ground and working environments, including different terrains and surfaces indoors and outdoors, to ensure the stable operation of the telescopic forklift in various situations.

The second one is the rim size DW25x28 used on Volvo wheel loaders. DW25x28 is a 1PC structure for TL tires. It is a newly developed rim size, which means that not many rim suppliers are producing this size. We developed DW25x28 based on the requirements of major customers who already have tires but need corresponding new rims. Compared with the standard design, our DW25x28 has a stronger flange, which means that the flange is wider and longer than other designs. This is the heavy-duty version DW25x28, designed for wheel loaders and tractors, and is a construction equipment and agricultural rim.

Its size and design features provide strong support and performance for these equipment under complex working conditions. Here are the main features of the DW25x28 rim:

1. High load capacity

The DW25x28 rim is suitable for equipment that needs to carry heavy loads, such as mining trucks, loaders, telescopic forklifts, etc. Its structural design can withstand the pressure and taxation of the equipment under heavy loads.

2. Enhanced durability

Since this wheel hub is usually used in environments such as mines and construction sites, the material of DW25x28 is usually high-strength steel, which has good impact resistance and wear resistance, and can maintain a long service life under harsh working conditions.

The rim is usually coated with an anti-corrosion coating to prevent rust and corrosion, especially in wet, muddy and chemical environments.

3. Stability and grip

The wide wheel frame with the corresponding tire width can improve the vehicle's grip and stability, especially when driving on soft soil, mud and rugged terrain. The wide contact area is conducive to dispersing the load and preventing the equipment from sinking into soft ground.

4. Adapt to wide frame design

The DW25x28 wheel design is usually used with wide tires. The tires can provide a larger contact area, which not only improves the traction and stability of the equipment on uneven ground, but also reduces the pressure on the ground and reduces ground damage.

In general, the characteristics of the DW25x28 wheel are high load capacity, enhanced durability, good stability and the design of wide tires of the whole vehicle, which can meet the needs of heavy equipment in harsh environments.

Why does Volvo wheel loader choose to use DW25x28 rims?

Volvo wheel loaders choose to use DW25x28 rims mainly for the following reasons to improve the performance and adaptability of the equipment:

1. Adapt to high-intensity and heavy-load conditions

The DW25x28 rim has a large width and a sturdy structure, which can withstand greater loads and high-intensity operations. Volvo loaders are usually used in heavy-duty operating environments such as mines, quarries, and construction sites. Choosing DW25x28 rims can ensure that the machine can still operate stably under heavy loads and meet the needs of high-load conditions.

2. Optimize traction and grip

This wide rim is suitable for installing large-size tires, which increases the contact area between the tire and the ground, thereby improving traction and grip. When working in soft, muddy or gravel terrain, the enhanced grip can help the loader avoid slipping, improve work efficiency, and ensure safe and reliable operation of the equipment in complex environments.

3. Extend tire life and reduce operating costs

The DW25x28 rim can evenly distribute the load on the tire, reduce single-point pressure, and reduce the local wear rate of the tire. This design can extend tire life and reduce downtime and maintenance costs caused by frequent tire replacement, which is of great significance to the overall operating cost.

4. Improve operating comfort

The combination of wide rims and matching wide tires can absorb more ground vibrations and impacts, reduce the driver's sense of vibration during operation, and improve operating comfort. This is especially important for long-term working conditions, which helps to maintain the operator's comfort and work efficiency.

5. Adapt to a variety of tire types and improve equipment applicability

DW25x28 rims are compatible with a variety of tire types (such as cut-resistant tires, anti-skid tires, etc.), and tires can be flexibly selected according to different working conditions. This allows Volvo wheel loaders to adapt to more diverse working environments, such as rocky ground, soft ground, slippery ground, etc.

6. Improve the safety of the equipment

Wide rims improve the stability of the loader while reducing the risk of tipping when carrying heavy objects, thereby improving the safety of the overall equipment. This stability is particularly important for working conditions involving the transportation of large or heavy materials, and can reduce the occurrence of accidents.

7. Support greater torque output

The structural design of the DW25x28 rim is conducive to bearing greater torque output, making the loader more efficient in acceleration, steering and lifting operations. This is particularly advantageous under high-intensity working conditions, and can help the loader give full play to its power advantages.

In summary, Volvo wheel loaders choose DW25x28 rims mainly to meet the needs of high-intensity operations while improving the stability, durability and adaptability of the equipment. It not only optimizes traction and load capacity, but also improves overall operating experience and safety, making it an ideal rim choice for heavy loaders.

The third is a 9.75x16.5 rim for Bobcat skid steer loaders. The 9.75x16.5 rim is a 1PC structural rim for TL tires. 9.75 means the rim width is 9.75 inches, and 16.5 means the rim diameter is 16.5 inches.

What are the advantages of using 9.75x16.5 rims on Bobcat skid steers?

There are several key advantages to using 9.75x16.5 rims on Bobcat skid steers:

1. Improved stability and grip

The 9.75x16.5 rim is wider and can be paired with wide tires, increasing the contact area between the tire and the ground. This design can effectively enhance grip and stability, especially for soft, muddy, or uneven construction ground.

2. Enhanced load capacity

This rim size and width allow it to withstand higher loads. This load advantage is particularly important for heavy-duty material handling conditions where skid steers are frequently operated, helping the machine perform well under heavy loads and extending the life of the equipment.

3. Reduced tire wear

The combination of wide rims and wide tires helps to disperse pressure, thereby reducing tire wear. For skid steers working on harder or rough ground, this rim choice can extend tire life and reduce operating costs.

4. Improve comfort

This combination of rims and wide tires can buffer some vibrations, making the machine run more smoothly on rugged terrain and improving the driver's operating comfort.

5. Flexible adaptation to various terrains

The tires adapted to the 9.75x16.5 rims can better cope with different working environments, whether it is mud, gravel or gravel, they can provide better performance.

In general, the 9.75x16.5 rims on skid loader not only improve the stability and load capacity of the machine, but also reduce the maintenance cost of the tires. It is an economical and practical choice.

All our products are designed and produced according to the highest quality standards. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use.

We are widely involved in engineering machinery, mining vehicle rims, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

The following are the rims of various sizes that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Nov-13-2024