Construction Indonesia is one of the leading international trade fairs in the construction and infrastructure sector, held annually at the Jakarta International Expo (JIExpo). Organised by PT Pamerindo Indonesia, a renowned organiser of several major industrial exhibitions in Indonesia, the show is a central platform for the display of advanced construction technologies, machinery, tools and services. It attracts leading industry professionals and decision makers from across the construction industry, making it the best place to network and meet potential buyers and key contacts. Construction Indonesia has become the largest and longest-standing international exhibition for construction structures, engineering, procurement and equipment.

The exhibition covers a wide range of topics, including construction engineering, heavy machinery, tools, infrastructure, and cutting-edge technologies such as 3D printing and geospatial surveying technology. Its products range from building materials such as bricks and concrete to advanced equipment such as drones for aerial photography and robotic surveying.

An important aspect of Construction Indonesia is its role in the development of Indonesian cities and infrastructure. As a showcase for innovation, it promotes the modernisation of the construction industry and helps improve the country's infrastructure. Located in Jakarta, the trade and economic hub of Southeast Asia, the exhibition provides a strategically important platform for domestic and international business relations.

Highlights of the exhibition include interactive sessions, product demonstrations and expert interviews. Construction Indonesia is also known for its networking events that provide space for industry-specific discussions and building valuable connections. The central location and excellent facilities of the JIExpo venue make it an ideal choice for exhibitors and visitors.

Attendees include engineers, project managers and decision-makers from both the public and private sectors who use the exhibition as a platform to exchange expertise and a barometer of the latest industry trends and challenges.

All in all, Construction Indonesia is an important meeting point for construction industry professionals seeking the latest technology, equipment and partnerships to improve project dynamism and efficiency. It provides a unique opportunity to get directly into the heart of Southeast Asia's booming construction industry.

The products exhibited at this exhibition include excavators, backhoes, articulated vehicles, cranes, forklifts, drilling rigs, dump trucks, asphalt pavers, scrapers, rollers, hydraulic vehicles, special vehicles, power generation, manual and power tools, site lighting, pliers, HVAC, pipe cutters, hydraulic tools, formwork and scaffolding, construction and interior design, site management, facility management, work safety, cleaning services and systems, communications and navigation, water and sanitation, ports and airports, roads, railways, bridges, landscaping, drainage systems, aggregates, concrete, steel, aluminum, bricks, wood, ceramics, marble and granite, and mechanical parts.

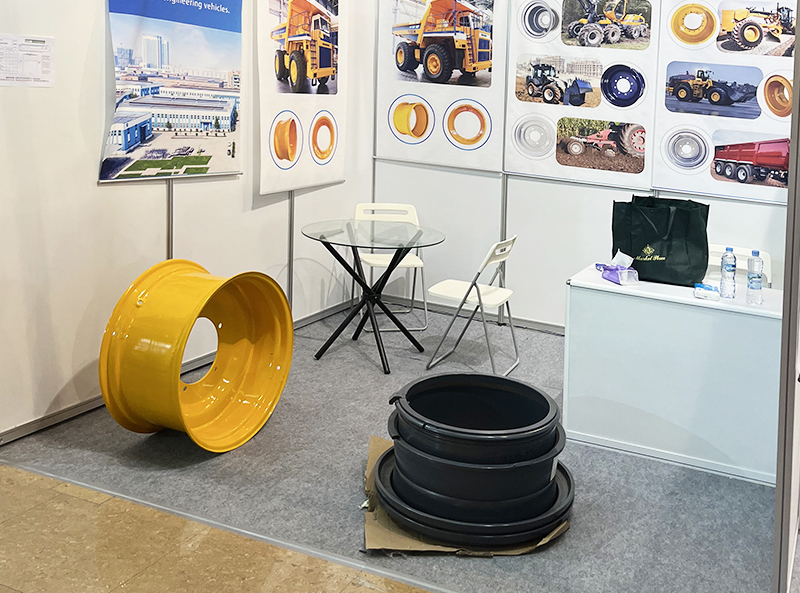

Our company was also invited to participate in this exhibition and brought several rim products of different specifications.

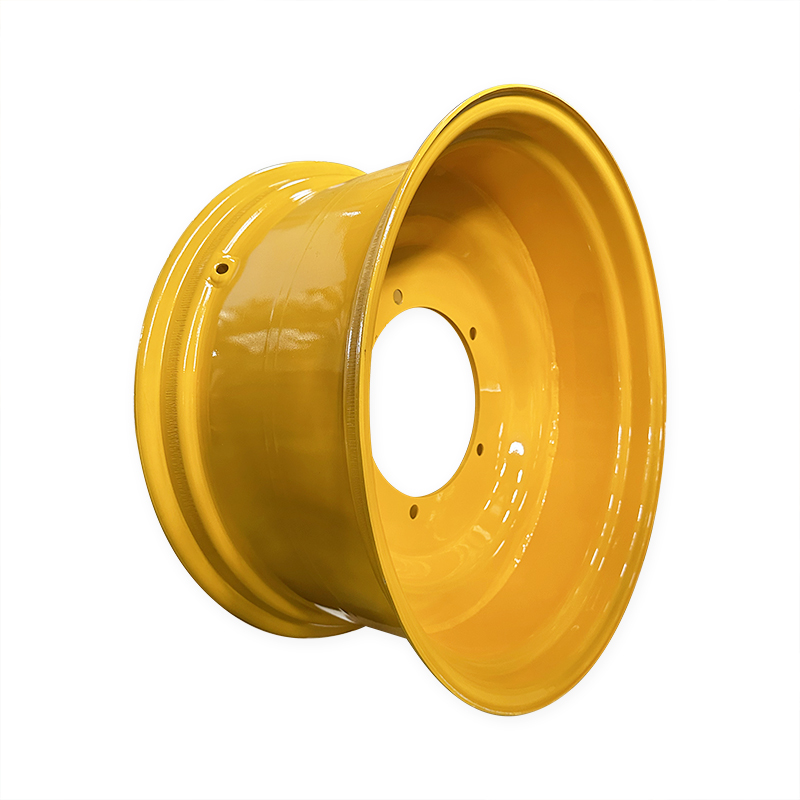

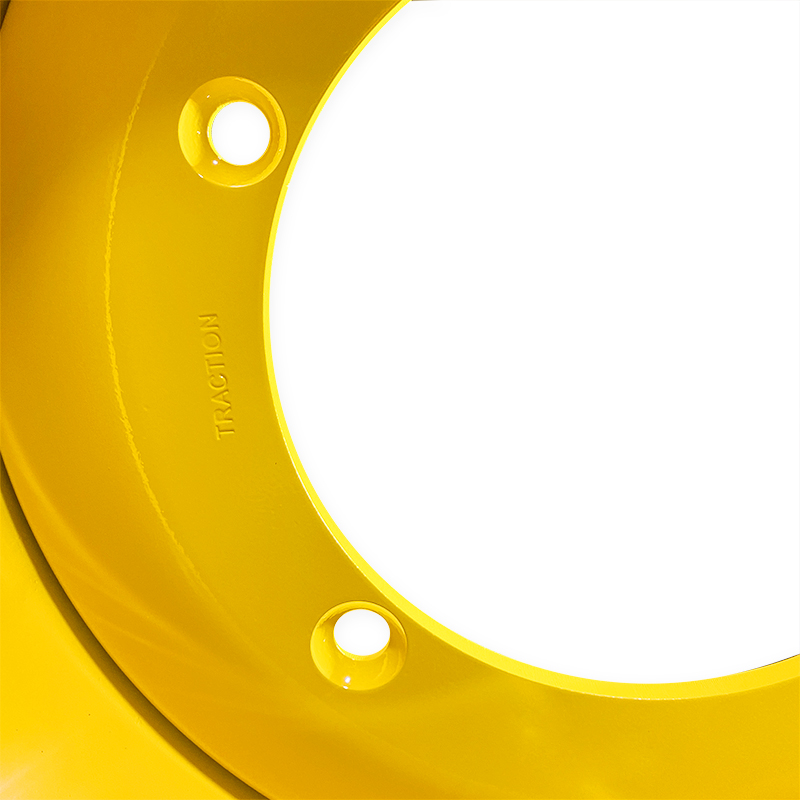

The first one is a 14x28 one-piece rim used on industrial vehicle telescopic forklifts. The corresponding tire of the 14x28 rim is 480/70R28. 14x28 is widely used in engineering vehicles such as excavators and telescopic forklifts.

The 14x28 rims produced by our company have been equipped for telescopic forklifts of Russian OEMs. This rim has the following characteristics:

1. Durability and reliability: Telescopic forklifts are usually used for material handling and aerial work in harsh environments such as construction sites and building sites, so the rims need to have sufficient durability and reliability to cope with various complex working environments and conditions.

2. Carrying capacity: The rim needs to be able to withstand the weight of the telescopic forklift itself and the additional load during lifting or handling, so it needs to have a high carrying capacity.

3. Stability: For aerial work equipment such as telescopic forklifts, stability is crucial. Therefore, this rim may be designed to provide good stability and balance to ensure a safe aerial work environment.

4. Adaptability: This rim may be designed to adapt to different ground and working environments, including different terrains and surfaces indoors and outdoors, to ensure the stable operation of the telescopic forklift in various situations.

We can also produce the same type of one-piece rim 15x28, which is widely used in the Russian market and has been unanimously recognized by customers.

What Are The Advantages Of Small Telescopic Forklifts?

Small telescopic forklifts are widely used in many fields, and their advantages include:

1. Versatility: Telescopic forklifts can be equipped with a variety of attachments (such as forks, buckets, hooks, etc.), enabling them to perform a variety of tasks, such as handling, loading and unloading, lifting and stacking. Especially in narrow work sites, the flexibility of telescopic forklifts is particularly prominent.

2. Telescopic arm design: Compared with traditional fixed arm forklifts, the telescopic arm design allows the equipment to adjust the operating radius and height as needed, which makes it more effective in carrying goods at high altitudes and over long distances. The goods can be moved from a distant place by telescopic arms without moving the chassis.

3. Compact body design: The body of a small telescopic forklift is usually compact, suitable for operation in a small space, such as construction sites, warehouses and narrow roads.

4. High maneuverability: Small telescopic forklifts usually have all-wheel steering function, can flexibly turn in a small space, and have off-road capabilities, which can cope with complex terrain and different ground conditions.

5. Stability and safety: Telescopic forklifts are usually equipped with automatic balancing and stabilization systems, which can adjust the center of gravity of the forklift according to the extension of the arm to ensure stability during operation. The operator can also monitor the operation through equipment such as cameras and sensors to increase the safety of the operation.

6. Easy to transport and maintain: Due to its small size and light weight, small telescopic forklifts are relatively easy to transport. Its structure is relatively simple, and the maintenance and servicing costs are low.

These advantages make small telescopic forklifts very practical equipment in fields such as construction, agriculture, logistics and warehousing.

Industrial rims We can also produce multiple sizes of the following vehicles:

| Tele Handler | 9x18 | Backhoe loader | DW14x24 |

| Tele Handler | 11x18 | Backhoe loader | DW15x24 |

| Tele Handler | 13x24 | Backhoe loader | W14x28 |

| Tele Handler | 14x24 | Backhoe loader | DW15x28 |

| Tele Handler | DW14x24 | Material Handler | 7.00-20 |

| Tele Handler | DW15x24 | Material Handler | 7.50-20 |

| Tele Handler | DW16x26 | Material Handler | 8.50-20 |

| Tele Handler | DW25x26 | Material Handler | 10.00-20 |

| Tele Handler | W14x28 | Material Handler | 14.00-20 |

| Tele Handler | DW15x28 | Material Handler | 10.00-24 |

| Tele Handler | DW25x28 | Skid steer | 7.00x12 |

| Other Industrial vehicles | 16x17 | Skid steer | 7.00x15 |

| Other Industrial vehicles | 13x15.5 | Skid steer | 8.25x16.5 |

| Other Industrial vehicles | 9x15.3 | Skid steer | 9.75x16.5 |

The second one is the 13.00-25/2.5 five-piece rim used on mining dump trucks. The 13.00-25/2.5 rim is a 5PC structure rim of TL tires and is commonly used in mining dump trucks. This rim has the following characteristics:

1. Strong load-bearing capacity: This specification of tire is suitable for high-load conditions and can provide good support in heavy-duty transportation tasks.

2. Wear resistance and grip: Large-size tires usually have enhanced wear resistance and can provide excellent grip, especially in muddy or rocky road conditions.

What should be paid attention to in the transportation of mining dump trucks?

When using mining dump trucks for transportation, safety and efficiency are essential. Since mining dump trucks are usually used to transport heavy materials such as ore, sand and gravel, and the environment is mostly complex mines or construction sites, special attention should be paid to the following points:

1. Loading precautions

Uniform loading: Ensure that the materials are evenly distributed in the car body to avoid excessive eccentric loading to prevent the vehicle from overturning or losing control.

Loading weight control: The maximum load capacity of the dump truck must not be exceeded. Overloading will not only damage the vehicle, but may also cause brake failure or tire burst.

Loading height: The loaded material must not exceed the height of the side panel of the car body to prevent the material from sliding during transportation and affecting the road and other vehicles.

2. Precautions during driving

Slow-speed driving: In mines or construction sites, the road surface is usually rugged. Slow-speed driving can better control the vehicle and avoid bumps that cause the vehicle body to become unstable.

Keep a safe distance: There are many vehicles in the mining area. Keep an appropriate safe distance to ensure sufficient reaction time to avoid collisions or accidents.

Turning precautions: Due to the large size and heavy weight of the dump truck, slow down and increase the turning radius when turning to avoid the car body from overturning.

Observe the road conditions: Observe the road conditions at any time, especially in muddy, waterlogged or gravelly sections, be careful not to slide or get stuck.

3. Precautions for unloading

Choose a flat ground: When unloading, choose a flat ground to avoid tilting of the vehicle body, especially under heavy loads, tilting will cause the vehicle to roll over.

Slowly lift the car body: When lifting the car body, do it slowly to ensure the stability of the car body, and pay attention to whether there are materials stuck or incomplete dumping.

Ensure rear safety: When unloading, make sure there are no people or other vehicles behind the car to avoid injury or damage caused by material sliding.

4. Regular inspection and maintenance

Brake system inspection: The brake system is a key component of mining dump trucks. Before transportation, ensure that the brakes are sensitive to avoid brake failure on slopes or complex sections.

Tire inspection: The road conditions in the mining area are complex and tires are easily damaged. Check the wear of the tires regularly and maintain appropriate tire pressure.

Hydraulic system inspection: Ensure that there is no leakage in the hydraulic system and that the hydraulic oil is sufficient to prevent the car body from being unable to rise and fall normally during unloading.

Lighting and warning equipment: Ensure that all lights, horns, and warning lights work properly, especially when working at night in a mine with poor lighting.

5. Driver safety

Receive professional training: Mining dump trucks are usually large in size and complex to operate. Drivers should receive professional training and be familiar with vehicle performance and skills to deal with emergencies.

Wear safety equipment: Drivers should wear necessary safety equipment such as seat belts, helmets, and protective gloves when operating.

Avoid fatigue driving: Mining work is usually high-intensity, and drivers should arrange rest time reasonably to avoid accidents caused by fatigue driving.

6. Precautions for slope operation

Slow down when going uphill: When loading, drive slowly uphill to avoid sudden acceleration that may cause the vehicle to slip.

Speed control when going downhill: When going downhill, low gear and brakes should be used reasonably to avoid long-term braking that may cause the brakes to overheat and fail.

Parking operation: When parking on a slope, use the parking brake and park the vehicle on a flat surface as much as possible to prevent slipping.

Among mining vehicles, we can also produce multiple sizes of the following vehicles:

| Mining dump truck | 10.00-20 | Underground mining | 10.00-24 |

| Mining dump truck | 14.00-20 | Underground mining | 10.00-25 |

| Mining dump truck | 10.00-24 | Underground mining | 19.50-25 |

| Mining dump truck | 10.00-25 | Underground mining | 22.00-25 |

| Mining dump truck | 11.25-25 | Underground mining | 24.00-25 |

| Mining dump truck | 13.00-25 | Underground mining | 25.00-25 |

| Rigid Dump truck | 15.00-35 | Underground mining | 25.00-29 |

| Rigid Dump truck | 17.00-35 | Underground mining | 27.00-29 |

| Rigid Dump truck | 19.50-49 | Underground mining | 28.00-33 |

| Rigid Dump truck | 24.00-51 | Wheel loader | 14.00-25 |

| Rigid Dump truck | 40.00-51 | Wheel loader | 17.00-25 |

| Rigid Dump truck | 29.00-57 | Wheel loader | 19.50-25 |

| Rigid Dump truck | 32.00-57 | Wheel loader | 22.00-25 |

| Rigid Dump truck | 41.00-63 | Wheel loader | 24.00-25 |

| Rigid Dump truck | 44.00-63 | Wheel loader | 25.00-25 |

| Dollies and Trailers | 25-11.25/2.0 | Wheel loader | 24.00-29 |

| Dollies and Trailers | 33-13.00/2.5 | Wheel loader | 25.00-29 |

| Dollies and Trailers | 13.00-33/2.5 | Wheel loader | 27.00-29 |

| Dollies and Trailers | 35-15.00/3.0 | Wheel loader | DW25x28 |

| Dollies and Trailers | 17.00-35/3.5 | Grader | 8.50-20 |

| Dollies and Trailers | 25-11.25/2.0 | Grader | 14.00-25 |

| Dollies and Trailers | 25-11.25/2.0 | Grader | 17.00-25 |

| Dollies and Trailers | 25-13.00/2.5 | Dollies and Trailers | 25-13.00/2.5 |

We are the No.1 off-road wheel designer and manufacturer in China, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards, and we have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

Our company is widely involved in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce for different fields:

Engineering machinery sizes: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 13.00-25, 14.00-25, 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Mining sizes: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-34, 15.00-35, 17.00-35, 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Forklift sizes are: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15, 6.50-15, 7.00 -15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Industrial vehicle sizes are: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5, 9.75x16.5, 16x17, 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28

Agricultural machinery sizes are: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 11x18, W8x18, W9x18, 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x30, DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Our products have world-class quality.

Post time: Sep-13-2024