The measurement of truck rims mainly includes the following key dimensions, which determine the specifications of the rim and its compatibility with the tire:

1. Rim diameter

The diameter of the rim refers to the inner diameter of the tire when it is installed on the rim, measured in inches. This is the basic parameter of the truck rim specification. For example, a 22.5-inch rim is suitable for a 22.5-inch tire inner diameter.

2. Rim width

The rim width refers to the distance between the inner edges of the two sides of the rim, also measured in inches. The width determines the width selection range of the tire. Rims that are too wide or too narrow will affect the safety and service life of the tire.

3. Offset

The offset is the distance from the centerline of the rim to the mounting surface. It can be positive offset (extending to the outside of the rim), negative offset (extending to the inside of the rim), or zero offset. The offset affects the distance between the rim and the truck suspension system, and also affects the steering and stability of the vehicle.

4. Hub Bore

This is the diameter of the center hole of the rim, which is used to match the axle head size of the axle. Ensuring that the center hole diameter is correctly matched allows the rim to be properly mounted on the axle and maintain stability.

5. Pitch Circle Diameter (PCD)

The bolt hole spacing refers to the distance between the centers of two adjacent bolt holes, usually measured in millimeters. The correct matching of PCD parameters ensures that the rim can be securely mounted on the hub.

6. Rim shape and type

Truck rims have different shapes and types depending on the usage scenario, such as single-piece, split, etc. The measurement methods of different types of rims are slightly different, but the basic size measurements are consistent.

When measuring truck rims, it is recommended to use dedicated measuring tools such as calipers and gauges to ensure that the data is accurate. In addition, the commonly used measurement units are inches and millimeters, and the units should be consistent when measuring.

HYWG is China's No. 1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced to the highest quality standards.

During the manufacturing process of the rims, we will conduct a series of tests on the products to ensure that the products delivered to customers are complete and high-quality. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies to maintain a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

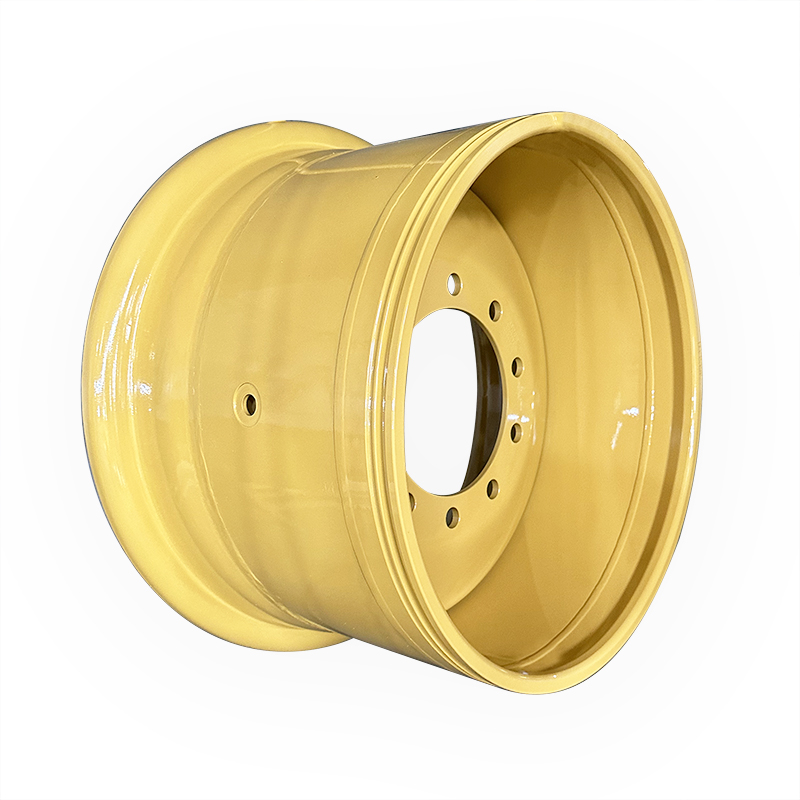

The 14.00-25/1.5 rims provided by our company for the CAT 919 grader have been highly recognized by customers during use.

In construction machinery such as graders, "14.00-25/1.5" rims usually include the following important parameters:

1. Tire width (14.00)

"14.00" means the cross-sectional width of the tire is 14 inches. This parameter usually indicates the cross-sectional width of the tire, and the width of the rim needs to match the tire width to ensure that the tire is installed correctly.

2. Rim diameter (25)

"25" means the diameter of the rim is 25 inches. This value must be consistent with the inner diameter of the tire to ensure that the tire can be installed on the rim smoothly.

3. Rim type (1.5)

"/1.5" indicates the width factor of the rim or the shape of the rim. The 1.5 here can be understood as the cross-sectional width of the rim. For rims of this specification, tires of corresponding widths are generally adapted to ensure stability and safety.

This rim specification is usually used for large construction machinery and is suitable for heavy loads and complex working conditions, such as in mines, construction sites and other harsh terrain environments. Ensuring that the rim and tire specifications match is critical to the smooth operation of the equipment and the service life of the tire.

What Are The Advantages Of Using Our 14.00-25/1.5 Rims On The Cat919 Grader?

The CAT919 grader uses 14.00-25/1.5 rims with the following advantages, which improve the performance and durability of the grader in engineering operations:

1. Strong load-bearing capacity

The 14.00-25/1.5 rim design is suitable for wide engineering tires and can withstand heavy loads. This is very important for large graders like the CAT919 to ensure that the equipment remains stable under fully loaded conditions.

2. Enhanced grip and traction

The wider 14.00-inch tire with this rim can provide a larger contact area, thereby improving grip. This configuration is particularly beneficial in complex working conditions such as soft soil, gravel roads and muddy areas, and can improve the traction and operating efficiency of the grader.

3. Higher stability

The 25-inch rim diameter and 1.5 rim width factor make the tire tighter and more stable when installed, reducing the swing amplitude during operation. This is essential for leveling operations that require precision, which can reduce deviation and improve flatness.

4. Durability and impact resistance

14.00-25/1.5 specification rims are usually made of sturdy steel, adaptable to various harsh working environments, and have excellent impact resistance. In this way, when working on rough or hard ground, the rims and tires are not easy to deform or damage.

5. Versatility to adapt to harsh road conditions

This rim size is suitable for high-strength tires and can operate on a variety of ground such as rocks, gravel, sand, etc. After using this rim, the CAT919 grader has enhanced adaptability and can complete a variety of complex terrain leveling tasks, improving construction efficiency.

6. Reduce tire wear and extend service life

Wide tires matching 14.00-25/1.5 rims can distribute pressure more evenly during operation and reduce local wear of tires. This helps to extend the service life of tires and reduce replacement costs.

In summary, the use of 14.00-25/1.5 rims on CAT919 graders can significantly improve the stability, durability and operating efficiency of equipment, and is particularly suitable for high-load operations in harsh environments.

Our company is widely involved in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims in different fields that our company can produce:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Nov-20-2024