The rim load rating (or rated load capacity) is the maximum weight that the rim can safely bear under specific operating conditions. This indicator is very important because the rim needs to withstand the weight of the vehicle and the load, as well as the impact and stress caused by factors such as terrain, speed, acceleration, etc. The rim load rating mainly works in the following ways:

1. Ensure safety: The rim load rating provides a safety range to ensure that there will be no structural damage or deformation when the vehicle carries its specified weight. If the load exceeds the rim load rating, the rim may suffer fatigue cracks or deformation, causing the connection between the tire and the rim to fail, increasing the risk of a blowout or accident.

2. Optimize vehicle performance: When the rim matches the vehicle's load capacity, it can optimize the overall performance of the vehicle and avoid excessive stress on the tire and suspension system. The rim load rating can disperse pressure, ensure a smooth vehicle ride, and improve work efficiency.

3. Extend service life: A reasonable rim load rating can reduce wear on the rim and tire and extend their service life. Long-term use above the rim rated load will accelerate metal fatigue, reduce the service life of the rim, and increase maintenance costs.

4. Meet work requirements: In heavy machinery such as mining vehicles and engineering vehicles, different working conditions have different requirements for rim loads. The selection of rim rated loads ensures that the vehicle can complete the specified tasks safely and effectively.

5. Improve operational stability: The rim rated load is closely related to the balance of the vehicle. A reasonable rated load can ensure the operational stability of the vehicle and avoid rollover or deviation caused by overloading, especially when driving on uneven terrain.

It is very important to choose a rim that matches the vehicle's rated load, which determines the safety, performance and reliability of the vehicle.

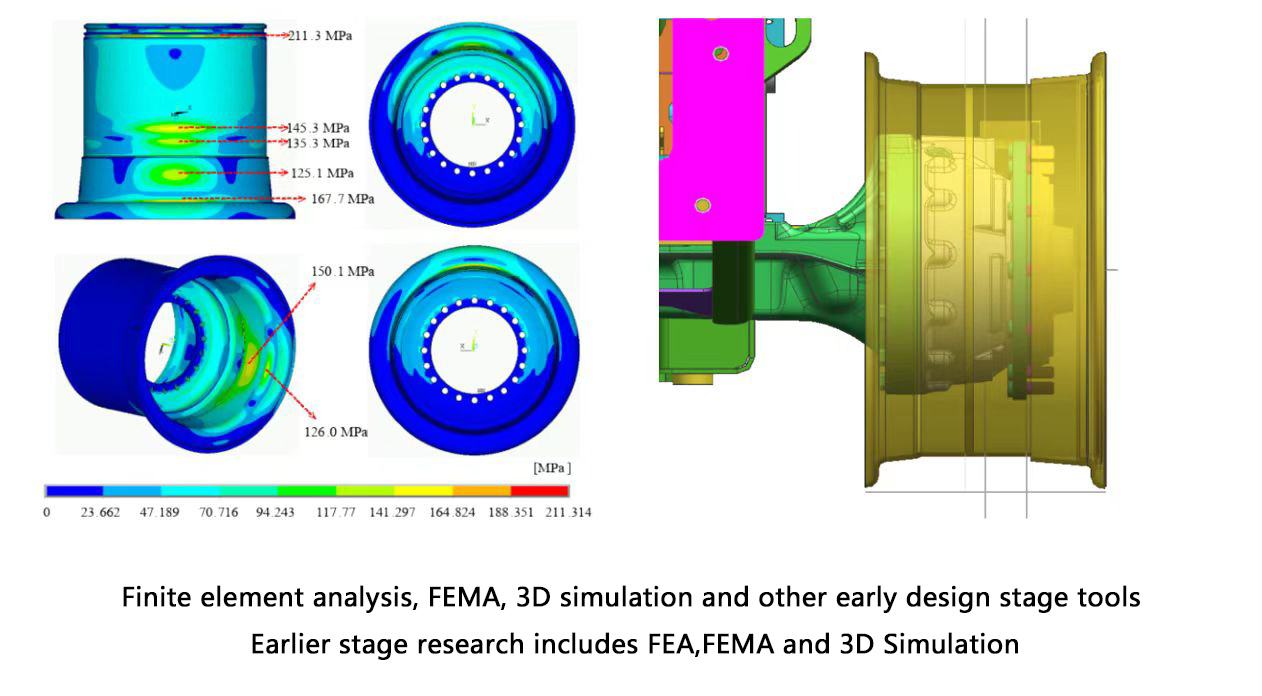

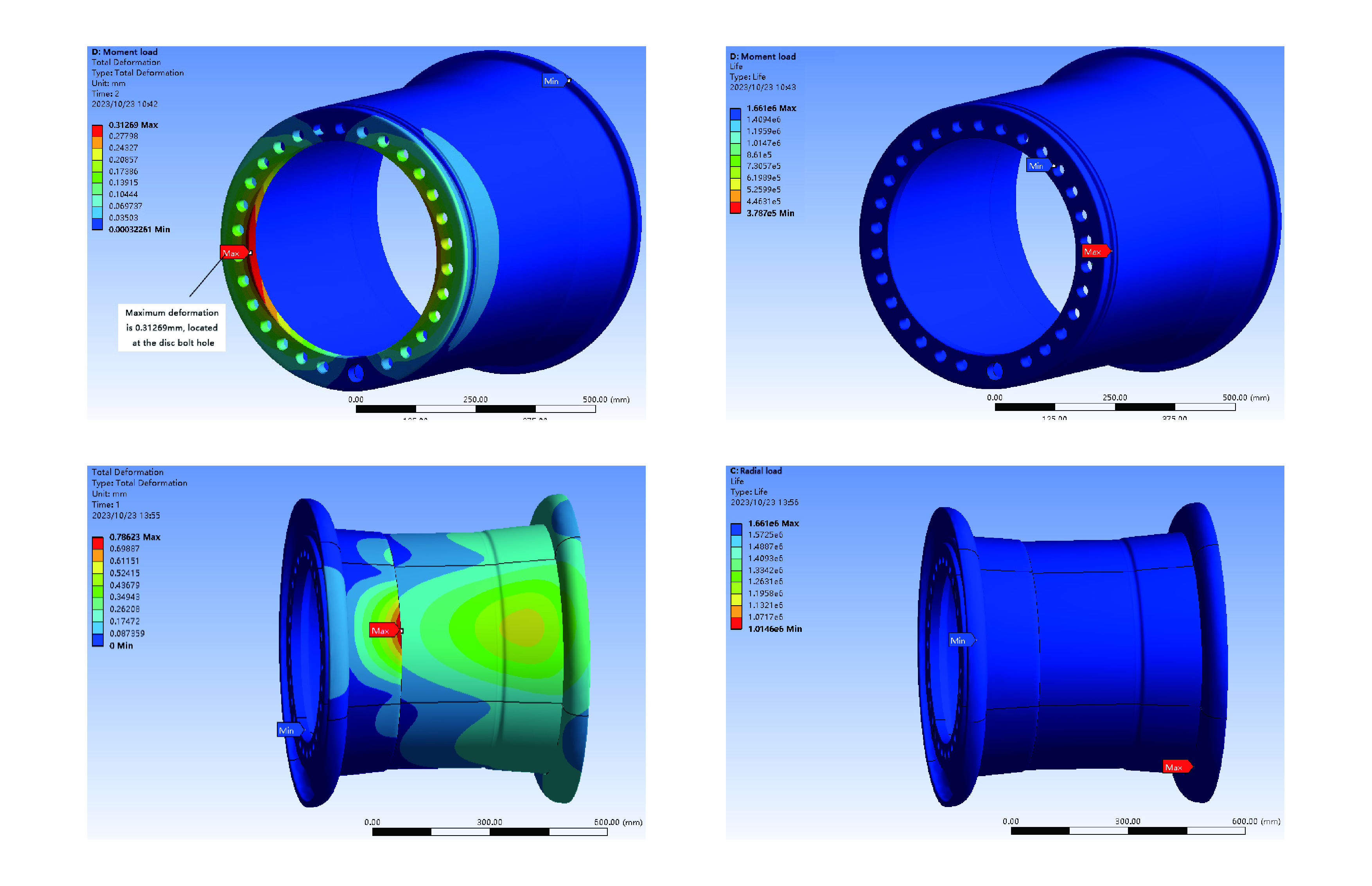

During the manufacturing process of the rim, we will conduct a series of tests on the product to ensure that it is a complete and high-quality product delivered to the customer. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use.

In mining vehicles, due to the need to carry heavy loads and the harsh terrain and working conditions, the requirements for rims are also very high. Rims working in such terrains usually need to have super load-bearing capacity, durability and safety.

We are China's No. 1 off-road wheel designer and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have more than 20 years of wheel manufacturing experience. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

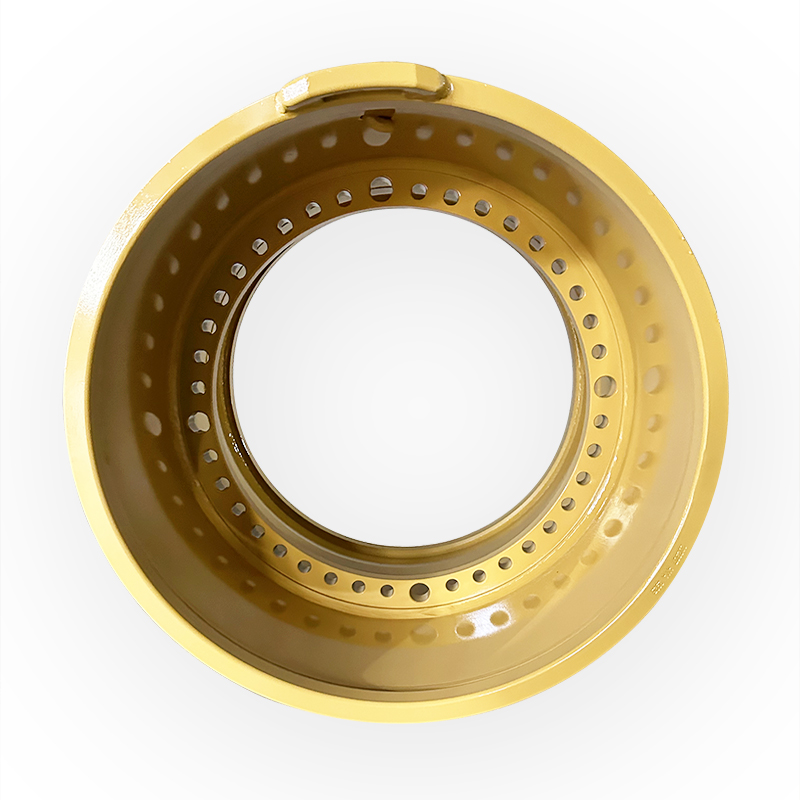

The 25.00-29/3.5 rims produced by our company for CAT R2900 underground mining vehicles have been highly recognized by customers during use.

"25.00-29/3.5" is a way of expressing the rim specification. It is a 5PC structure rim for TL tires and is usually used for rim and tire selection for heavy vehicles.

25.00: This is the width of the rim in inches (in). In this case, 25.00 inches refers to the bead width of the rim, which is the width of the tire mounting part.

29: This is the diameter of the rim in inches (in), that is, the diameter of the entire rim, which is used to match tires of the same diameter.

/3.5: This is the flange width of the rim in inches (in). The flange is the protruding part of the outer ring of the rim that supports the tire. The 3.5-inch flange width can provide additional stability and support, which is suitable for vehicles with high load requirements.

Rims of this specification are usually used for heavy equipment such as mining transport trucks and loaders. The width and diameter of the rim determine the large tires that can be matched, and the flange width provides the necessary support to cope with harsh terrain and heavy load conditions.

What are the advantages of using CAT R2900 in underground mining?

CAT R2900 is a loader (LHD) designed for underground mining. Its advantages are reflected in high performance, durability, operating comfort and convenient maintenance. It is very suitable for small underground spaces and harsh working conditions.

1. Powerful power

Equipped with Cat C15 engine, it is powerful and can provide excellent traction to adapt to high-load operations in underground mines.

Using ACERT technology, it meets emission standards, reduces exhaust emissions, is more environmentally friendly, and has high fuel efficiency and reduces operating costs.

2. High load capacity

R2900 has a rated load capacity of up to 14 tons, which can improve mining efficiency. Its design can transport more ore at a time, reduce the number of round trips, and improve production efficiency.

3. Excellent maneuverability

R2900 has a compact body and a small turning radius, which is very suitable for narrow tunnels and complex terrain in underground mining.

The advanced suspension system provides good stability and controllability, and remains stable in rugged underground passages.

4. Durability and reliability

Adopting a sturdy structural design and high-strength materials, it is suitable for harsh environments in underground mining, such as wet, dusty, rugged and other conditions.

CAT equipment is known for its durability, which reduces equipment failure rate and downtime and improves production efficiency.

5. Operation comfort

Equipped with a comfortable cab, low noise and vibration, and ergonomic seat design improves operator comfort.

The cab has a good view and a modern control system, making operation easier and more efficient, reducing operator fatigue.

6. Advanced hydraulic system

The efficient hydraulic system improves bucket loading capacity, increases loading and unloading speed, and improves work efficiency.

The hydraulic system optimizes fuel consumption, reduces heat generation, and is more suitable for long-term high-intensity work.

7. Convenient maintenance and maintenance

R2900 is designed with multiple convenient maintenance entrances, so that operators can quickly perform maintenance and inspections, reducing maintenance time.

Cat's remote monitoring technology is used to help the mining team monitor the operating status of the equipment in real time, and predictive maintenance reduces the occurrence of failures.

8. Safety performance

CAT R2900 is equipped with a variety of safety features, such as emergency braking system, sliding protection device, automatic fire extinguishing system, etc., to ensure the safety of operators in underground operations.

The cab has a protective structure to effectively ensure the safety of the operator, especially in the event of collapse or rock falling in the mine.

With its high load capacity, excellent maneuverability and durable design, CAT R2900 has significant advantages in underground mining, which can effectively improve mine production efficiency and ensure operational safety. It is particularly suitable for complex mine environments such as deep wells and narrow tunnels.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce for different fields:

Engineering machinery sizes: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 13.00-25, 14.00-25, 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Mining sizes: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-34, 15.00-35, 17.00-35, 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Forklift sizes are: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15, 6.50-15, 7.00 -15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Industrial vehicle sizes are: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5, 9.75x16.5, 16x17, 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28

Agricultural machinery sizes are: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 11x18, W8x18, W9x18, 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x30, DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Our products have world-class quality.

Post time: Nov-04-2024