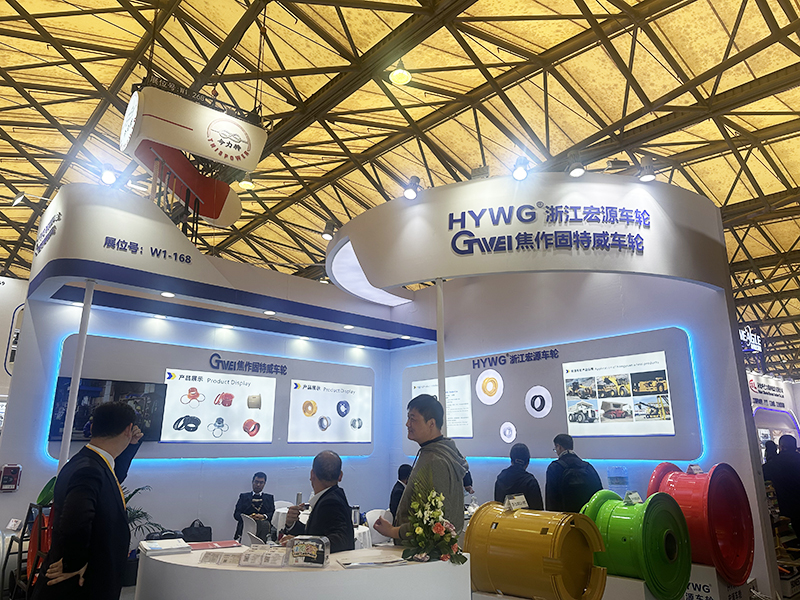

Bauma CHINA will be held in Shanghai from November 26 to November 29, 2024.

Bauma CHINA is China's international exhibition of construction machinery, building materials machinery, mining machinery and engineering vehicles. It is the pulse of the industry and the engine of international success, the driving force of innovation and the market, second only to the main exhibition of bauma in Munich, Germany.

As the largest and most important industry event in Asia, more than 3,000 companies from more than 40 countries and regions around the world participated in the exhibition, attracting more than 200,000 professional visitors, covering multiple fields such as construction, mining, and transportation. Bauma CHINA is a community for the Asian construction machinery industry and a gateway for international companies to enter the Chinese market and for Chinese companies to enter the global market.

The exhibition will display solutions for construction machinery, construction machinery, mining equipment, accessories and products. The main exhibits include conventional equipment such as construction and engineering machinery, including excavators, loaders, bulldozers, and graders. Special equipment such as tunnel boring and bridge construction. Mining machinery includes underground mining vehicles, mining dump trucks, crushing and screening equipment, etc. Intelligent mining solutions and automation technologies. Building materials machinery includes concrete mixing plants, prefabricated parts production equipment, cement machinery, etc. There are also various parts and accessories including hydraulic systems, transmission parts, electrical systems, tires and rims, etc. Digital management and remote control technology. New energy and intelligent technology: electrification, hydrogen energy, hybrid equipment. Innovative products such as intelligent control, unmanned driving, and AI-assisted technology.

This exhibition has four highlights:

1. Carbon neutrality and green technology: innovative equipment and solutions that meet the global construction and mining industry emission reduction targets, and a concentrated display of electrification and hydrogen energy equipment, such as new energy mining trucks and electric loaders.

2. Digitalization and intelligence: the latest solutions for smart construction sites and smart mines, including unmanned driving technology and remote equipment monitoring systems.

3. Combination of internationalization and localization: Many international brands (such as Caterpillar, Volvo Construction Equipment, Komatsu, Liebherr, etc.) will compete with Chinese brands (such as Sany Heavy Industry, Zoomlion, XCMG, Shantui, etc.).

4. Release of innovative products and technologies: Many companies choose bauma CHINA as the first platform for the launch of new products, and are expected to release a number of world-leading equipment and technologies.

HYWG, as China's No. 1 off-road wheel designer and manufacturer and the world's leading expert in rim component design and manufacturing, was invited to participate in this exhibition and brought several rim products of different specifications.

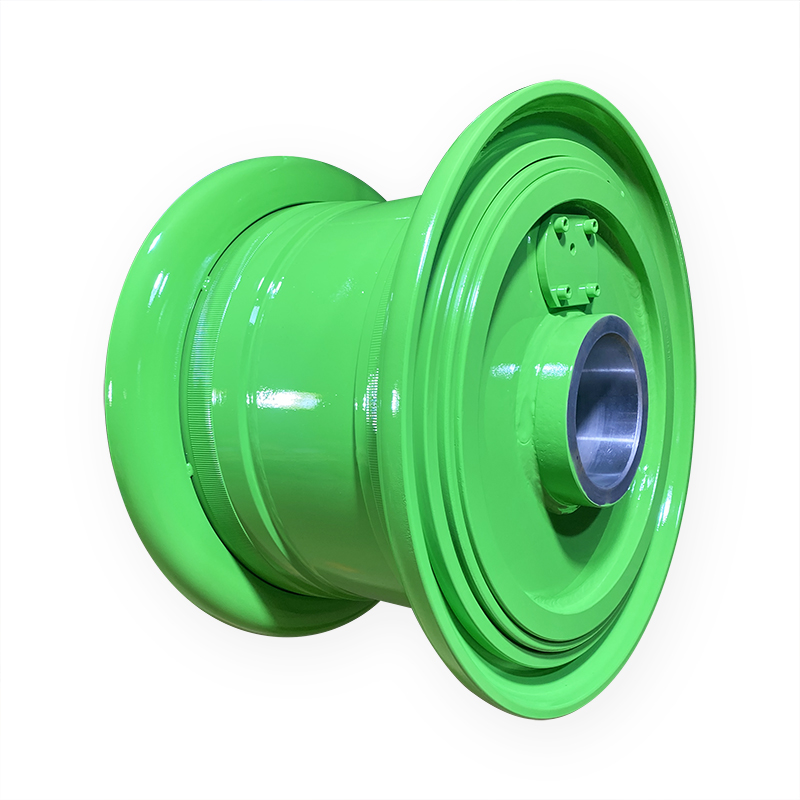

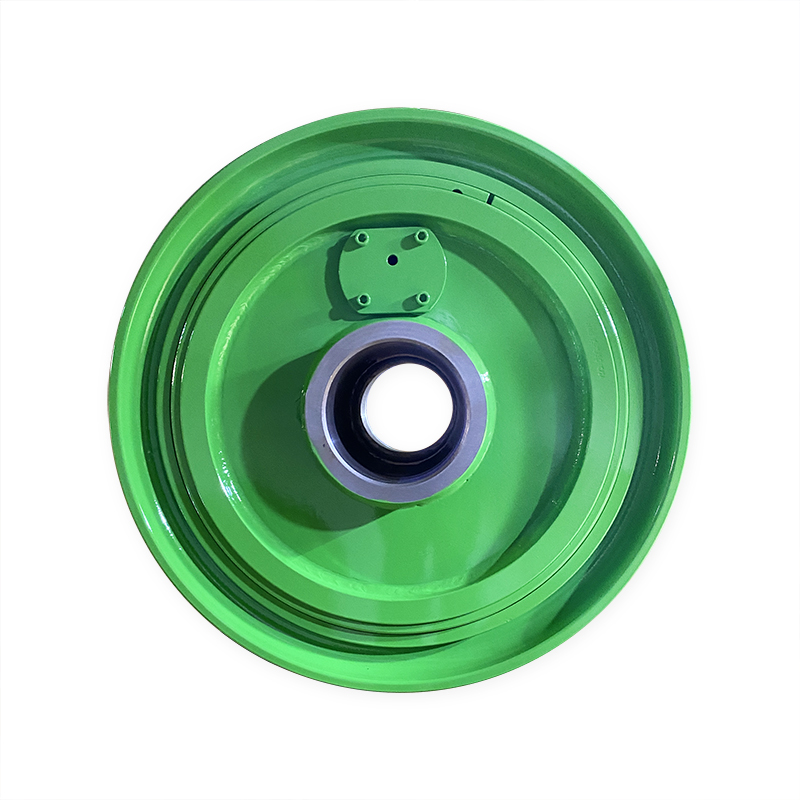

The first one is the 17.00-35/3.5 rim used on the Komatsu 605-7 rigid dump truck. The 17.00-35/3.5 rim is a 5PC structure rim of the TL tire.

Komatsu is one of the world's leading manufacturers of construction machinery and mining equipment. It is known for its high performance, reliability and technological innovation, and plays an important role in the global construction machinery industry. The rigid dump trucks it produces are widely used in mining work.

Since the Komatsu 605-7 rigid dump truck is widely used in open-pit mines to transport ore, waste rock and slag, the terrain is complex, and it has been driving on steep slopes, gravel roads and muddy roads for a long time, it requires high-strength and durable rims to adapt to such harsh terrain. For this reason, we specially developed and produced 17.00-35/3.5 rims.

17.00-35: Indicates the size of the rim. 17.00: The width of the rim is 17 inches. 35: The diameter of the rim is 35 inches. 3.5: means the width of the lock ring is 3.5 inches. The tire models suitable for this rim are usually: 24.00-35, 26.5-35,

29.5-35, these tires are known for their strong load-bearing capacity and wear resistance, and are mostly used on heavy equipment.

What Are The Advantages Of Using Our 17.00-35/3.5 Rims For Komatsu 605-7 Rigid Dump Trucks?

1. Perfect matching

Excellent adaptability: Our 17.00-35/3.5 rims are designed for 35-inch tires and fully match the standard tires of Komatsu 605-7.

Optimized performance: Ensure the close combination of tires and rims to improve driving stability and durability.

2. High load-bearing capacity

Support high-load transportation: Komatsu 605-7 has a design load-bearing capacity of up to 60 tons. Our rims are made of high-strength steel and can withstand the extreme loads in the transportation of high-density materials such as ore and waste.

Strong anti-deformation performance: Under high loads and complex working conditions, the rims can maintain a stable shape and performance to avoid tire loss due to deformation.

3. Durability and reliability

High-quality materials: Our rims are made of high-strength materials, which are heat-treated and anti-corrosion treated. They are impact-resistant and wear-resistant, and perform well in harsh environments.

Long life: Even in high-frequency operations such as mines, the service life of the rims can be effectively extended and the replacement frequency can be reduced.

4. Advantages of split design

Easy installation and maintenance: The split-design lock ring and side ring make tire installation and removal faster, reducing downtime caused by rim problems.

Improved safety performance: The split structure reduces the risk of tire and rim separation when transporting heavy-loaded materials, improving the safety of transportation operations.

5. Adaptability to complex working conditions

Adaptability to mining environments: Komatsu 605-7 often works in open-pit mines and steep slopes. Our rims have excellent grip transmission and anti-slip performance, ensuring stability on gravel roads and slippery roads.

Extreme temperature resistance: The surface treatment and material design of our rims enable them to maintain stable performance in high temperature (such as desert mining areas) and low temperature (such as plateau or cold mining areas) environments.

6. Improve the overall efficiency of equipment

Improve fuel economy: The lightweight and high rigidity design of the rims can reduce rolling resistance and indirectly reduce fuel consumption.

Improve work efficiency: Reduce non-productive time caused by equipment problems by reducing the replacement frequency of tires and rims and optimizing the transportation process.

7. Reduce operating costs

Reduce tire wear: The precise design of our rims can effectively reduce abnormal wear of tires under high load conditions and extend tire life.

Reduce maintenance costs: The rugged and durable design reduces the need for frequent repairs and replacements, thereby reducing comprehensive maintenance costs.

8. Technical service support

Our company also provides after-sales technical services, which can further enhance customers' trust and satisfaction with the product, thereby improving the overall operating efficiency of customers using Komatsu 605-7. Therefore, the 17.00-35/3.5 rim produced by our company can well help Komatsu 605-7 to achieve efficient, safe and economical operation in complex working environments.

The second type is the 15.00-25/3.0 rim used in port machinery. The 15.00-25/3.0 is a 5PC structure rim of TL tires.

The application advantages of 15.00-25/3.0 rims on port machinery (such as tire cranes, reach stackers, forklifts, container trucks, etc.) are significant, especially in heavy loads, frequent operations and complex environments. . It mainly has the following advantages and features:

1. High load-bearing capacity specially designed for heavy-duty transportation. Port machinery needs to frequently transport heavy goods (such as containers, bulk cargo, etc.). The 15.00-25/3.0 rims are made of high-strength steel, which can maintain stability and stability under high load conditions. Security. It has strong anti-deformation ability. Even if it operates for a long time under heavy load conditions, the rim can effectively resist deformation and ensure reliable mechanical operation.

2. Improves the operating efficiency of the vehicle. The 15.00-25/3.0 rim is suitable for a variety of tire models (such as 17.5-25 or 20.5-25), which can provide excellent grip and stability in complex road conditions at the port (such as slippery Excellent performance on asphalt or gravel roads). The high-rigidity and low-elasticity design of the rim makes port machinery more responsive during speed-up, braking and steering operations, helping to improve overall operating efficiency.

3. Corrosion-resistant design of the rim. The port environment has high humidity and salt spray. The rim has undergone special anti-corrosion treatment (such as galvanizing or spraying anti-corrosion coating), which can effectively resist rust and extend the service life. At the same time, it has strong impact resistance. Mechanical vibration and external impact are often encountered during loading and unloading of goods. The high-strength structure of the rim can ensure long-lasting reliability under harsh conditions.

4. The rim adopts a split design. The split structure of the lock ring and side ring makes tire replacement more convenient and reduces the downtime of port machinery due to tire or rim maintenance. At the same time, the service life is extended. The precise tire support design reduces the pressure and abnormal wear of the sidewall, extending the comprehensive service life of the tire and rim.

5. Strong adaptability to complex road surfaces. Port machinery often works on slippery asphalt, gravel roads or metal loading and unloading platforms. The 15.00-25/3.0 rims provide reliable traction and support to ensure the machinery's performance in various environments. Stable operation. The rim uses optimized materials and heat treatment processes, which can maintain excellent performance in high-temperature summers or low-temperature cold winters, and is not easy to crack or deform, enhancing high and low temperature adaptability:

6. Durable rims reduce replacement frequency and repair costs, thereby reducing long-term operating costs of port equipment. The longer rim and tire life cycle indirectly increases the utilization rate and profitability of machinery.

The application of 15.00-25/3.0 rims on port machinery can not only meet the needs of high strength, heavy load and frequent operations, but also significantly improve the overall efficiency of the equipment through excellent reliability and low maintenance.

All products we produce are designed and produced according to the highest quality standards. We have a R&D team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies to maintain a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use.

It is widely used in engineering machinery, mining vehicle rims, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. It is the original rim in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere. supplier.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Dec-06-2024