HYWG Develop And Produce 13.00-33/2.5 rims for Sleipner E250 Dollies and Trailers

The Sleipner E250 Dollies and Trailers are part of Sleipner's specialized hauling equipment, designed to handle heavy loads and operate efficiently in mining and construction environments. These Dollies and Trailers are used with large mining trucks, enabling them to increase payload capacity and improve efficiency in transporting bulk materials over rough terrain.

.jpg)

There are many advantages to choosing Sleipner E250 for mine transportation,

1. Increased payload capacity

By attaching a trailer or dolly to a tractor truck or articulated dump truck, the total vehicle load can be increased. This means fewer trips to transport the same amount of material, improving the overall efficiency of the mine.

2. Efficient material handling

The use of trailers and dollies helps optimize material handling at the mining site. It allows large amounts of material to be transported in one trip, reducing idle time and fuel consumption.

3. Cost-effective

The ability to transport more material in fewer trips reduces fuel and labor costs. Fewer trips can also reduce maintenance costs per vehicle by reducing equipment wear.

4. Enhanced maneuverability in confined spaces

Although the Sleipner E250 trailers and dollies are large and heavy, they are designed for efficient operation, even in confined spaces. The articulated frame allows them to move smoothly over rough terrain and through narrow corners, making them ideal for complex mining sites with narrow or uneven passages.

To ensure optimal performance and safety, the wheels and rims of the Sleipner E250 must be able to support extremely heavy loads, cope with rough terrain and provide reliability in the demanding conditions of mining operations.

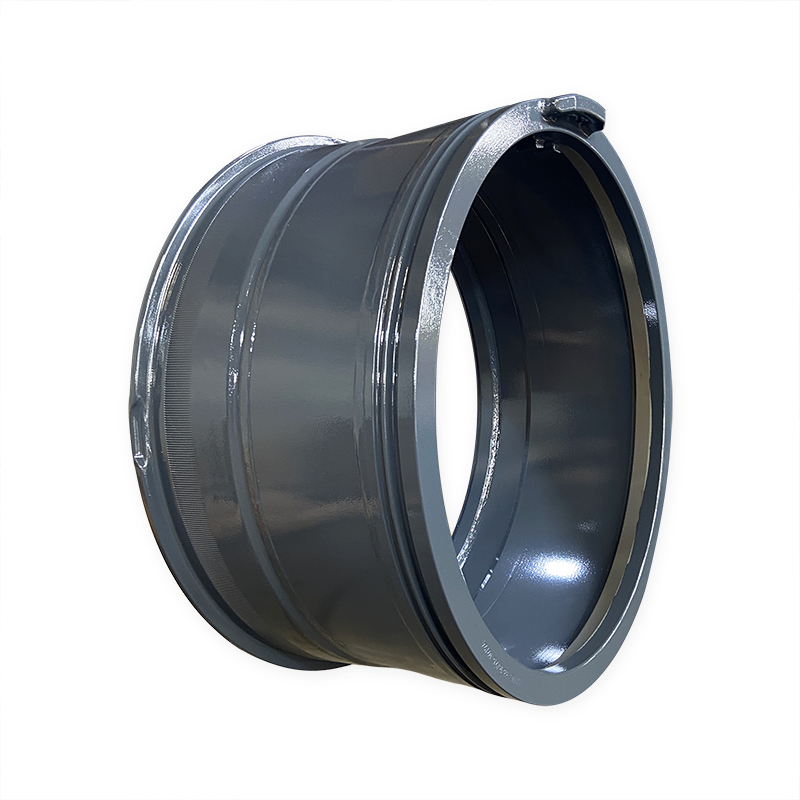

We therefore developed and produced rim 13.00-33/2.5, which corresponds to the typical large tires used in articulated dump trucks and trailers, requiring high load capacity and durability, which is essential for stability and load-bearing capacity on rough terrain.

13.00-33/2.5 rims are commonly used in industrial rims for heavy machinery and mining equipment, and can also be used in other industrial equipment such as construction vehicles, earth-moving machinery or material handling equipment.

In order to withstand the heavy loads and harsh conditions in industrial and mining applications, we will select the right materials and design heavy-duty structures to withstand abrasive conditions, including sharp rocks, rugged terrain and extreme weather conditions. To ensure a long service life, these rims are usually coated with corrosion-resistant materials to prevent them from rusting when exposed to moisture, chemicals or other environmental factors.

HYWG is China's No. 1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

During the manufacturing process of our rims, we will conduct a series of tests on the products to ensure that they are complete and high-quality products delivered to customers. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for Volvo, Caterpillar, Liebherr, John Deere and other well-known brands.

What are the advantages of choosing our 13.00-33/2.5 rims for Sleipner E250 Dollies and Trailers?

1. High load-bearing capacity

The 13.00-33/2.5 rims are designed for heavy equipment and can withstand high loads. They are suitable for Sleipner E250 for mining transportation or other heavy material handling needs. With a width of 13 inches, it can provide a wider contact area, increase the contact between the tire and the ground, reduce ground pressure, increase load capacity, and ensure stability and safety in harsh terrain.

2. Optimized durability

The rims are made of steel or forged steel materials, which are extremely durable and can withstand the impact and wear of heavy machinery. They are especially suitable for extreme conditions in mining environments. The design of anti-corrosion coating can effectively reduce the erosion of moisture, chemicals and oxides on the rims and extend their service life.

3. Improve equipment stability

The 13.00-33/2.5 rim can provide stronger lateral support and ensure the stability of the vehicle when operating on rough terrain. Especially in mining areas, the terrain often changes. The use of this specification of rims can significantly improve the handling and stability of the equipment during heavy-load transportation.

4. Adapt to high-pressure working environment

The rim can withstand high pressure and maintain excellent performance under conditions of high load and high tire pressure. Sleipner E250 often needs to carry extremely high weight in mining areas, and the rim needs to provide strong support and pressure resistance. The 13.00-33/2.5 rim is carefully designed to meet this challenge, ensuring the matching of the tire and rim and preventing it from falling off or breaking.

5. Versatile adaptation

Since the 13.00-33/2.5 rim is suitable for a variety of mining trailers and carts, it can provide flexible configuration options and customize the tire and rim combination according to specific load requirements and working environment. After the Sleipner E250 is equipped with this rim, it can be compatible with more different types of tires, increasing the applicability and flexibility of the vehicle.

6. Improve efficiency and productivity

Due to the high wear resistance and high load-bearing capacity of the 13.00-33/2.5 rim, the running time of the Sleipner E250 can be greatly extended, reducing the frequency of tire replacement and downtime maintenance, and improving the productivity and operating efficiency of the equipment. Maintaining efficient operation for a long time contributes to the efficient operation of mining operations.

Therefore, choosing our company's 13.00-33/2.5 rim as a Sleipner E250 accessory can significantly improve its load capacity, stability, durability and safety, and improve equipment production efficiency by reducing maintenance costs. It is suitable for heavy-duty operating environments such as mining areas, can withstand high loads and maintain reliable performance under harsh conditions, and is an ideal choice for heavy-duty material transportation and high-load operations.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Feb-19-2025