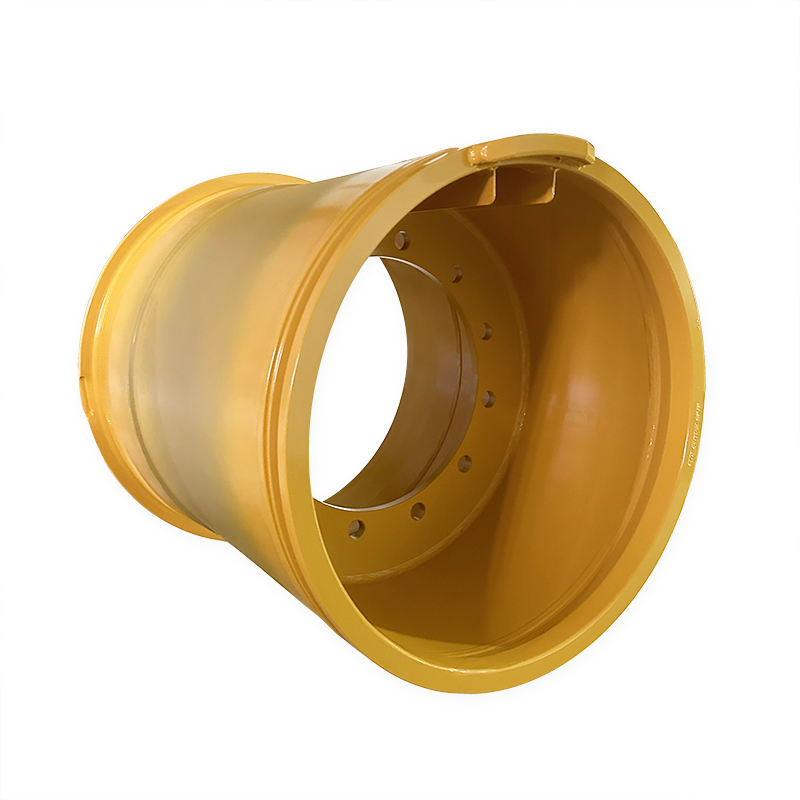

HYWG Provides 24.00-25/3.0 Rims For Volvo A30E Articulated Dump Trucks

Volvo A30E is an articulated dump truck produced by Volvo (Volvo Construction Equipment), which is widely used in construction, mining, earthmoving and other transportation tasks under harsh working conditions. Due to the harsh terrain of the working environment and the need for high load-bearing capacity and better traction, it is necessary to use the 24.00-25/3.0 large-size rims designed by our company for heavy equipment.

24.00 means the rim width is 24 inches, which can be matched with extra-wide tires to provide a larger contact area and stability.

25 means the rim diameter is 25 inches, which is suitable for large-size tires, such as 24.00R25.

3.0 means the rim flange thickness is 3 inches, which enhances the structural strength and load-bearing capacity of the rim.

.jpg)

The Volvo A30E articulated dump truck equipped with 24.00-25/3.0 rims will bring the following advantages, especially when transporting heavy materials and operating in complex terrain:

1. Higher load capacity to support high load requirements: The 24.00-25/3.0 rims are suitable for wide-base large-size tires and can withstand the full load weight of the Volve A30E of nearly 29 tons. In heavy-load scenarios such as mining areas and construction sites, its high-strength design can effectively prevent the rim from deformation or damage and ensure transportation safety.

2. Improved stability. Larger ground contact area: With wide-base tires, the vehicle's ground contact area is increased, which helps reduce ground pressure and enhances vehicle stability and anti-roll capability. Driving on muddy ground, gravel roads or slippery environments shows stronger grip and stability.

3. Stronger durability, impact and fatigue resistance: The 24.00-25/3.0 rim is made of high-strength steel, which can withstand frequent impact and vibration in mining areas and construction sites, and extend the service life of the rim. Excellent anti-corrosion performance, suitable for harsh outdoor environments, especially in high humidity and corrosive working conditions.

4. Reduce tire wear and improve rim and tire matching: The 24.00-25/3.0 rim is precisely designed and has a high fit with wide-base tires, reducing uneven force, reducing the risk of abnormal tire wear, and extending tire service life, thereby reducing operating costs, reducing the frequency of tire replacement, and reducing overall maintenance costs.

5. Improve transportation efficiency and optimize driving performance: The combination of wide-base tires and rims provides stronger traction and rolling performance, allowing the Volvo A30E to run smoothly even when fully loaded, and significantly improves transportation efficiency. It can adapt to complex working conditions and is more suitable for continuous transportation tasks in steep slopes in mining areas and large-scale projects, improving the overall operating capacity of the equipment.

6. Multi-piece structure, easier maintenance: The 24.00-25/3.0 rim adopts a multi-piece design, which is easy to disassemble and maintain. No complex tools are required when changing tires, which can shorten downtime and improve equipment utilization.

In summary, the use of 24.00-25/3.0 rims provides Volvo A30E with significant performance improvements, especially in stability, durability and efficiency under high load and complex working conditions. In addition, the rims also have low maintenance costs and long service life, making it a cost-effective rim configuration option!

We are China's No. 1 off-road wheel designer and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have mature technology in the research and development and production of mining vehicle rims, which are widely involved in mining vehicles such as mining dump trucks, rigid dump trucks, underground mining vehicles, wheel loaders, graders, mining trailers, etc. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. You can send me the rim size you need, tell me your needs and troubles, and we will have a professional technical team to help you answer and realize your ideas.

How Does a Mining Vehicle Work?

Mining vehicles are key equipment in mining operations and are used to transport materials such as ore, rock, and soil. These vehicles include rigid dump trucks, articulated dump trucks, underground mine trucks, etc. Their working methods and designs vary depending on the mining environment (open-pit or underground mines). The following is the workflow of mining vehicles:

1. Loading: Such as electric shovels, hydraulic excavators or wheel loaders load ore and rocks into the cargo box of mining vehicles. The driver uses the vehicle's positioning system and the loader's control system to ensure that the load is evenly distributed to prevent uneven loading from affecting stability.

2. Transportation: Open-pit mines: Rigid dump trucks or articulated trucks transport ore from the mining area to the crushing station or processing plant. It is usually necessary to drive on steep slopes and complex terrain.

Underground mines: Underground mine trucks transport materials in narrow tunnels, and their load capacity is usually small but more flexible.

3. Unloading

Automatic dumping: After arriving at the unloading location, the cargo bucket is tilted through the hydraulic system to quickly unload the materials.

Anti-skid design: The inside of the vehicle cargo bucket is often coated with wear-resistant materials to ensure that the materials slide out smoothly and reduce unloading resistance.

The efficient operation of mining vehicles depends on the coordination of power, control and durability systems. Different types of mining vehicles provide flexible and reliable transportation solutions according to working conditions. In the future, intelligent and environmentally friendly technologies will further promote the performance improvement and sustainable development of mining vehicles.

We not only produce mining vehicle rims, but also widely involved in engineering machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, etc.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Dec-16-2024