Ljungby L17 wheel loader is a heavy-duty wheel loader produced by Ljungby Maskin, usually used in construction, mining, earthmoving and other fields. L17 wheel loader focuses on loading, handling and stacking of bulk materials, has strong working ability and adaptability, and is particularly suitable for various harsh construction site environments.

Ljungby L17 wheel loader is an efficient, durable and harsh environment heavy equipment, widely used in mining, construction, earthwork and other industries. Its powerful power system, large-capacity bucket, hydraulic system, excellent off-road capability and comfortable and safe cab design make it an ideal choice for complex construction sites. Whether under high-load working conditions or on uneven and rugged ground, L17 can provide excellent working performance and is a reliable tool to improve work efficiency.

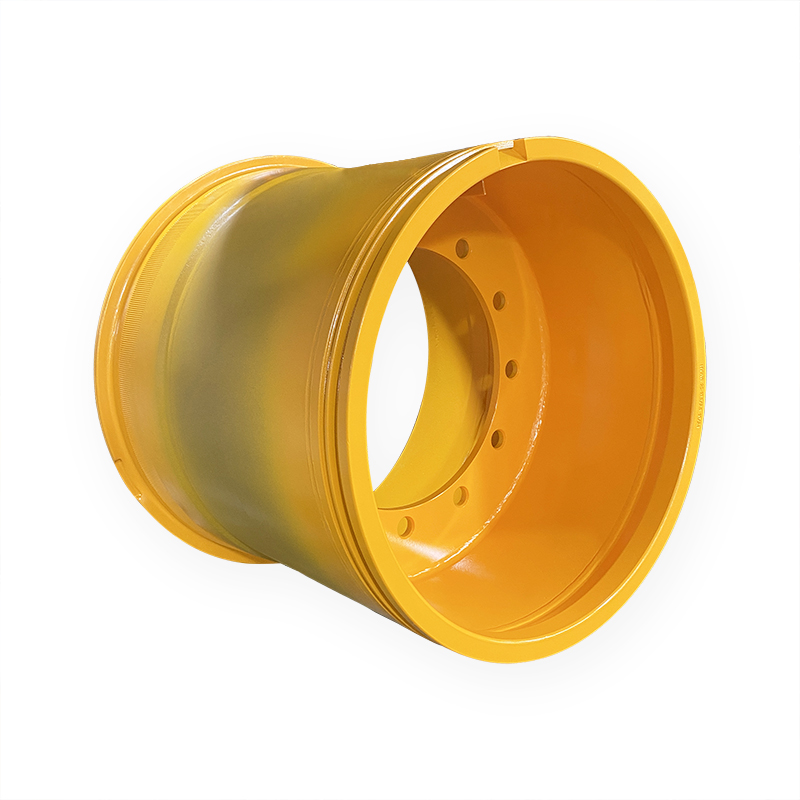

To ensure good traction, stability and durability in rugged terrain and heavy-load working environments. We have developed and produced 19.50-25/2.5 rims for use.

The 19.50-25/2.5 rim is a rim used for heavy engineering equipment and wheel loaders, and is usually suitable for the corresponding 19.50-25 size tires. This rim size is particularly suitable for working environments with large loads and complex terrain.

19.50 is the width of the tire (in inches), that is, the lateral width of the tire is 19.50 inches. 25 is the diameter of the tire (in inches), that is, the inner diameter of the tire is 25 inches. 2.5 refers to the width of the rim (in inches), which means that the width of the rim is 2.5 inches.

19.50-25/2.5 rims are usually used for heavy machinery and equipment such as mining transport vehicles, wheel loaders, and stackers, especially in working environments such as mines, quarries, and construction sites that require large loads and strong traction.

It is very suitable for equipment that requires larger tires and rims, such as heavy dump trucks and loaders of brands such as LJUNGBY, Caterpillar, and Volvo.

This type of rim is usually a steel rim with high strength and durability, suitable for harsh working environments. The combination design with the tire can withstand higher loads and is suitable for large-tonnage vehicles such as heavy trucks or loaders.

In mining, heavy mining trucks need to transport a large amount of ore, gravel or other heavy objects. This size of rim and tire combination can meet the transportation needs and provide stable performance.

In construction sites or earthmoving projects, heavy machinery such as loaders, bulldozers and stackers often require this rim configuration to operate efficiently in harsh terrain.

What are the advantages of choosing our 19.50-25/2.5 rim for LJUNGBY L17 wheel loader?

The 19.50-25/2.5 wheel rim produced by our company is a high-load-bearing rim suitable for heavy equipment, which can support large loads and high-intensity operations. Choosing this rim can increase the tire stability of the L17 wheel loader, and can effectively avoid excessive wear and damage to the tire when carrying heavy objects or working on rugged terrain.

Large rims ensure a larger contact area for the tire, which improves the traction and stability of the loader and helps provide better performance when handling bulk materials such as ore and construction materials.

The 19.50-25/2.5 rims, combined with high-performance tires, can significantly enhance the L17 wheel loader's ability to pass through complex and rugged terrain. The rims are suitable for installing large-size tires, which can better disperse pressure, reduce the risk of getting stuck, and provide stronger grip, especially in uneven working environments such as mines, quarries and earthworks.

The matching of rims and tires helps improve the performance of wheels on soft and muddy ground, improve vehicle maneuverability, and reduce slippage and idling.

The structural design of the 19.50-25/2.5 rims allows tires to wear more evenly under high-load conditions, which helps extend the service life of the tires. For wheel loaders, the choice of rims and tires will directly affect the vehicle's operating efficiency and operating costs.

Matching rim sizes helps reduce tire sidewall pressure, reduces the risk of tire deformation or over-inflation, and ensures that the tire remains in a stable working state, thereby improving the operational reliability of the entire equipment.

Equipped with 19.50-25/2.5 rims, the operating efficiency of the L17 wheel loader will be improved. Because the rim and the corresponding tire combination provide better stability and grip, the L17 wheel loader can complete heavy loading and handling operations more quickly and efficiently, reducing equipment downtime and maintenance costs. During loading, unloading and transportation, the stability and efficiency of the wheel can reduce tire sliding or vehicle bumps, improve operational smoothness and driver comfort, and further improve overall work efficiency.

Choosing our 19.50-25/2.5 rims means that the L17 wheel loader can adapt to heavier loads, especially in mines or other heavy-duty work sites. This rim size is used with high-strength tires to handle more extreme working environments, such as high loads, rugged terrain and long working hours in adverse weather conditions. Larger rim sizes can increase tire durability, making loaders more reliable under high-intensity operations and reducing equipment failures and maintenance frequency.

Wheel loaders with 19.50-25/2.5 rims can significantly improve traction during work, especially when transporting large materials. Larger rims and tires can better contact the ground, increase tire traction, and reduce the chance of idling and slipping.

In complex construction site environments, it can reduce truck skidding and wheel sliding, improve controllability and stability, help operators control equipment more accurately, and optimize workflows.

In summary, the advantages of using the 19.50-25/2.5 rim configuration Ljungby L17 wheel loader are mainly reflected in increased load capacity, enhanced stability, improved operating efficiency, and extended tire life. This rim size is suitable for heavy loads, complex terrain, and long-term high-intensity operations, which helps to improve the efficiency and reliability of the equipment while reducing maintenance and operating costs. In harsh environments such as mines, quarries, and earthwork excavation, the L17 wheel loader equipped with 19.50-25/2.5 rims can better cope with high-intensity work requirements.

HYWG is China's No. 1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have mature technology in the research and development and production of mining vehicle rims. We have extensive involvement in mining vehicles such as mining dump trucks, rigid dump trucks, underground mining vehicles, wheel loaders, graders, mining trailers, etc. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. You can send me the rim size you need, tell me your needs and troubles, and we will have a professional technical team to help you answer and realize your ideas.

We not only produce mining vehicle rims, but also widely involved in engineering machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, etc.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Dec-31-2024