The Volvo L180 wheel loader is a large-scale construction machine produced by Volvo Construction Equipment of Sweden. It is equipped with a high-performance engine, a large-capacity bucket and a powerful hydraulic system. It is a four-wheel drive, multi-purpose engineering loading equipment with excellent loading capacity, fuel efficiency and operating comfort, suitable for various heavy-load handling and loading and unloading operations. It is a member of its L series of medium and large loaders, mainly used in high-intensity working conditions such as heavy material handling, quarrying and mining, construction sites, ports and docks, and industrial applications.

The Volvo L180 has become one of the indispensable main equipment in large-scale engineering projects because it has several key advantages when working in harsh environments:

1. Strong power, easy to carry heavy loads

Equipped with a Volvo D13 turbocharged diesel engine with a power of 300~330 hp (about 220~246 kW);

Provides powerful torque to ensure excellent traction and digging force even when fully loaded;

Meets Tier 4F / Stage V emission standards and is environmentally friendly.

2. Efficient hydraulic and intelligent speed change system

Equipped with Load-sensing intelligent hydraulic system, which dynamically distributes hydraulic flow according to workload;

Volvo OptiShift technology: integrated locking clutch and reverse braking system, improving fuel efficiency by up to 15%;

Adaptive shift logic, responding smoothly to various terrains.

3. Excellent loading and lifting capabilities

Standard bucket capacity 5.0 – 6.2 m³;

Excellent lifting height and dumping distance, suitable for high-position loading;

Suitable for stone stacking, truck loading and heavy material transfer.

4. Comfortable operating experience

Equipped with Volvo Care Cab, it is spacious, quiet and has a wide view;

Air suspension seats, adjustable steering wheel, multi-function display;

Electro-hydraulic operated controls are lightweight, precise and reduce operator fatigue.

5. Strong durability and easy maintenance

Reinforced front and rear frame design to withstand high-intensity cyclic loads;

Modularly arranged maintenance points support rapid maintenance and fault diagnosis;

The Volvo Telematics (CareTrack) system enables remote monitoring of equipment status.

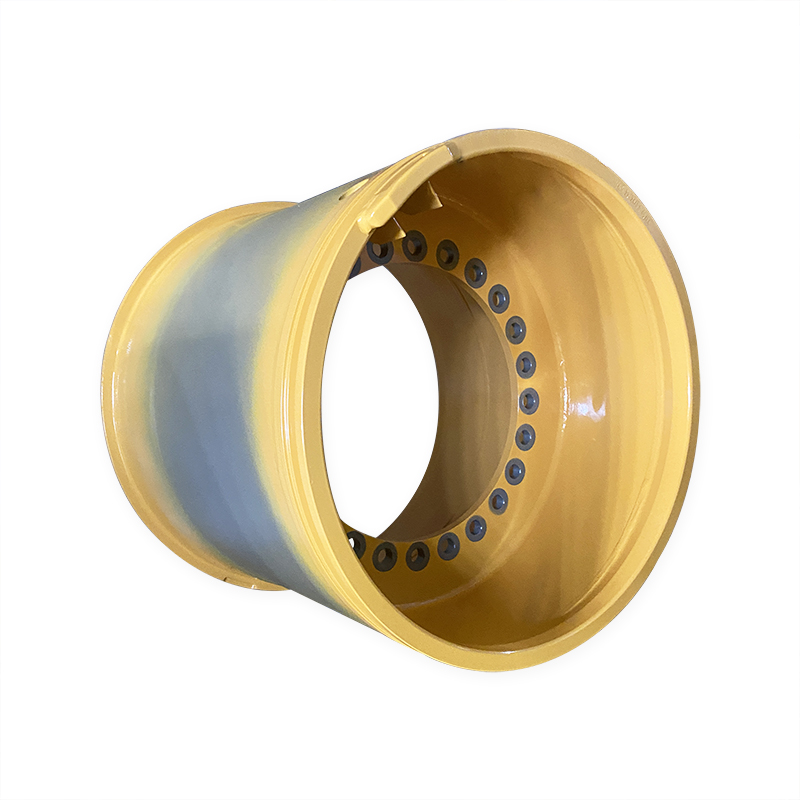

Wheel loaders are equipped with rims that carry huge loads and are also crucial accessories. As a large-scale construction machine, Volvo L180 is often used in heavy-load environments such as quarries, mines, and construction sites. Therefore, the rims it matches also need to have high strength, high load capacity, and good maintenance performance. For this reason, we designed 24.00-29/3.0 rims to match Volvo L180 .

The rim is made of high-strength steel, and its high strength can withstand the working load of heavy equipment up to tens of tons. It has strong impact resistance and is suitable for harsh working conditions such as mines, quarries, and construction waste yards. It is not easy to deform or break. The five-piece design is easy to disassemble and assemble, easy to maintain, and efficient in tire replacement, which is suitable for the rapid maintenance needs of mining areas. The locking ring and safety ring design prevents the tire from accidentally falling off due to pressure fluctuations or heavy load operations. It is matched with high-strength tires such as 29.5R29 and 750/65R29 to enhance grip and traction performance.

What are the advantages of using 24.00-29/3.0 rims on a Volvo L180?

When the Volvo L180 wheel loader is used with 24.00-29/3.0 five-piece rims, the performance of the whole machine in heavy-load and high-strength environments can be significantly improved, with the following main advantages:

1. Strong load-bearing capacity, matching the weight of the whole machine: Volvo L180 weighs about 28 tons and has a large workload. The 24.00-29/3.0 rim can stably withstand overweight loads to ensure safe operation.

2. Five-piece structure, efficient maintenance: including bottom ring, side ring, lock ring, safety ring, flange ring, easy to disassemble and assemble quickly, high efficiency of tire replacement, suitable for high-frequency operation needs in mining areas.

3. High strength and impact resistance: The rim is made of high-strength alloy steel to adapt to the continuous impact and lateral force of L180 in stone yards, mines and heavy load conditions.

4. Strong tire compatibility: It can adapt to large-size wide-base tires such as 29.5R29 and 750/65R29, improve traction and operation stability, and enhance the ability to pass through complex terrain.

5. Widely applicable fields: Whether in open-pit mines, steel mills, ports or large-scale earthmoving projects, it can ensure high attendance rate and equipment durability.

The Volvo L180 wheel loader chose our 24.00-29/3.0 rims, which is the result of comprehensive consideration of factors such as load-bearing capacity, tire adaptability, durability and vehicle design. This rim can ensure that the vehicle can work safely, stably and efficiently in extreme working conditions such as mines and construction sites , meeting the needs of heavy-duty transportation.

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards .

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing . We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Apr-23-2025