ATLAS COPCO MT5020 is a high-performance mining transport vehicle designed for underground mining applications. It is mainly used to transport ore, equipment and other materials in mine tunnels and underground working environments. The vehicle needs to adapt to the harsh environment of the mine and also needs to carry huge weight of materials during transportation, so there are special requirements for the specifications and performance of the rims.

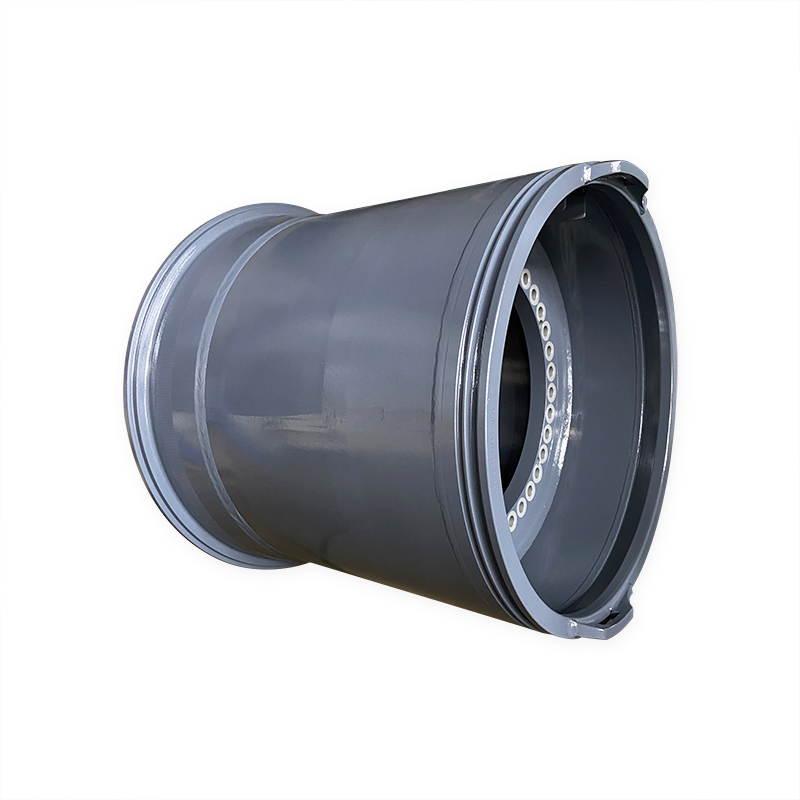

The 28.00-33/3.5 size rims developed and produced by our company for the ATLAS COPCO MT5020 vehicle meet the needs of the vehicle during driving:

1. Strong load-bearing capacity

The 28.00-33 size rim design matches heavy industrial and mining machinery and can withstand the material transportation weight of the mine truck up to 20 tons.

In the mining environment, the equipment needs to run at full load for a long time, which puts high demands on the load-bearing capacity of the rims and tires. The large size and structure of the 28.00-33 rim can provide sufficient strength and durability.

2. Stability

The wider rim (28 inches) provides a larger contact area, ensuring the stability of the tire on uneven ground.

When running on narrow mine tunnels or rugged roads, this rim size can significantly improve the driving stability and anti-overturning ability of the mine car, ensuring transportation safety.

3. High passability

The 33-inch diameter rim is suitable for high-diameter industrial tires, allowing the mine car to cross potholes, gravel and other obstacles in the mine area, ensuring high passability.

With a larger tire diameter, the mine car can maintain ground clearance and improve its adaptability on complex terrain.

4. Suitable for heavy-duty tires

Rims of 28.00-33 sizes are usually paired with large mining tires, such as Michelin XDR or Bridgestone V-Steel series. These tires can provide excellent traction and durability in harsh environments.

The 3.5 offset design optimizes the matching relationship between the rim and the tire, ensuring a more stable installation of the tire and the rim, thereby extending the tire life.

5. Improve work efficiency

Larger rim and tire sizes help mine cars maintain higher operating speeds when fully loaded, reduce transportation time, and improve operating efficiency.

In large underground mines that need to operate for long periods of time, using rims of this size can effectively reduce transportation cycles and improve the efficiency of ore or waste transfer.

6. Durability and life

Rims of 28.00-33/3.5 are usually made of high-strength steel and can withstand the impact and high load pressure common in mining areas.

The design of the rim enables it to withstand metal fatigue and corrosion in long-term use, thereby extending service life and reducing equipment maintenance costs.

7. Mining operation requirements

Underground mines are humid, hot, and the ground is mostly hard rock. Vehicles need tires and rims to provide strong support and protection.

Larger rim sizes can be paired with high-load tires to enhance grip and puncture resistance to meet the demanding requirements of mine transportation.

ATLAS COPCO MT5020 uses 28.00-33/3.5 rims, mainly to meet its high load capacity, high passability and stability requirements, while extending the service life of the equipment. This size of rim can perfectly match the large mining tires, ensuring that the mine car can operate efficiently in complex and harsh mining environments, and is an indispensable and important component of this model.

What Are Underground Mining Wheels?

Underground mining wheels are wheels designed specifically for underground mining operations and are mainly installed on underground mining equipment, such as mining trucks, loaders, drills or other transport vehicles. They are adapted to special working environments such as mine tunnels and have high load capacity, durability and adaptability to complex terrain.

The main features of underground mining wheels are as follows:

1. High load capacity: Underground mining equipment often transports heavy materials such as ore and waste, so the wheels must be able to withstand oversized loads while maintaining structural integrity under high pressure conditions.

2. Impact resistance: The ground in the mining environment is usually covered with hard materials such as rocks and gravel. The wheels need to have high impact resistance and be able to work normally under harsh conditions without deformation or damage.

3. Wear resistance: The underground working environment is humid and the ground friction is high. The wheel material needs to be wear-resistant to extend the service life and reduce the frequency of replacement.

4. Corrosion resistance: Underground mines may be wet, muddy or chemical substances (such as ore dust, acidic substances, etc.), so the material of the wheel needs to be corrosion-resistant, especially the coating treatment of steel rims.

5. Low profile design: Underground tunnels usually have limited space and vehicle height is restricted, so the design of wheels and tires is usually compact to meet the overall height requirements of the equipment.

6. Grip and stability:

The roads in underground mines are usually slippery and uneven, and the wheels need to provide sufficient grip and traction to ensure safe and stable movement of the vehicle.

Underground mining wheels can be divided into steel rims, aluminum alloy rims and polyurethane wheels according to different materials. The 28.00-33/3.5 rims provided by our company for ATLAS COPCO MT5020 are steel rims, which are more common and suitable for heavy loads and harsh environments. Aluminum alloy rims are lighter and suitable for weight-sensitive equipment. Polyurethane wheels are suitable for light equipment that requires higher shock absorption performance.

Underground mining wheels are installed on mining trucks or trailers to transport ore or waste in underground tunnels. They can assist equipment movement and are used for equipment such as cable laying machines and auxiliary maintenance vehicles to enable them to move freely in mines. In drilling and construction, drilling rigs, blasting equipment, etc. require wheels with high load and high passability. They can also be used to support underground machinery, including mechanical equipment such as scrapers and excavators, for loading and transport operations in mines.

Underground mining wheels are an important part of mining equipment and directly affect the performance and work efficiency of the vehicle. Its design takes into account high load capacity, durability and adaptability, ensuring that the vehicle can operate efficiently and safely in complex underground environments.

.jpg)

HYWG is China's No. 1 off-road wheel designer and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies to maintain a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing.

We not only produce mining vehicle rims, but also have a wide range of involvement in engineering machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, etc.

The following are the various sizes of rims in different fields that our company can produce:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Nov-28-2024