Mining wheels, usually referring to tires or wheel systems designed specifically for mining equipment, are one of the key components of mining machinery (such as mining trucks, shovel loaders, trailers, etc.). These tires and rims are designed to adapt to extreme working conditions, including high loads, complex roads and harsh weather conditions.

Mining wheels are mainly composed of the following parts:

1. Mining tires: used to support the weight of heavy mining machinery and adapt to complex road conditions such as rocks, gravel, mud and slippery roads. Common types include radial tires: strong wear resistance, suitable for long-term continuous operation. Bias tires: stronger sidewalls, suitable for short-distance transportation under extreme working conditions. Common specifications include 29.5R25, 33.00R51, 57R63, etc.

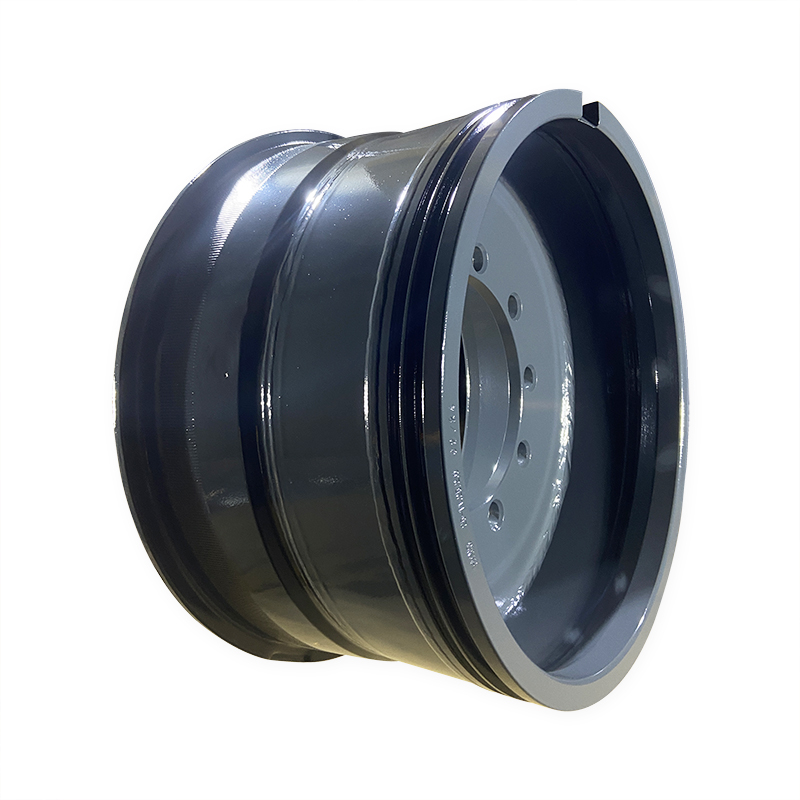

2. Rim: supports the tire and connects to the vehicle axle to provide structural strength. According to the equipment design, different tires match rims of corresponding specifications, such as 13.00-33/2.5 or 29.00-25/3.5. The mining rims produced by our company are widely used in mining vehicles such as Volvo, Caterpillar, Liebherr, and John Deere.

Due to the special use scenarios of mining wheels, they include many advantages:

1. High load-bearing capacity: Mining wheels need to support tens or even hundreds of tons of weight, and are designed with thickened materials and high-strength structures. For example, the tires of heavy-duty mining trucks can usually carry a load of 40-400 tons.

2. Wear resistance and puncture resistance: The mining environment is full of sharp rocks and hard ground. Tires must be impact-resistant and wear-resistant, while preventing punctures. The tire material is made of high-strength rubber compound.

3. Strong adaptability: Mining wheels need to cope with a variety of working conditions (slippery, muddy, gravel roads, etc.) and high-temperature environments (such as high temperature in the open-pit mine area or high temperature in the underground mine).

4. High stability and grip: The tire pattern design improves grip and ensures the stability of heavy vehicles on ramps or slippery roads.

Mining wheels can be divided into the following types due to different vehicle types and uses:

1. According to vehicle type:

Mining truck tires: giant tires (such as 59/80R63) used by CAT 793, Komatsu 960E, etc.

Lever loader tires: equipment used for load transportation, with slightly smaller tire size and higher flexibility.

Trailer tires: such as 13.00-33 used by Sleipner trailers, etc. Our company has developed and produced a variety of rims in the Sleipner trailer E series, which are highly recognized by customers in use!

2. According to use:

Underground mining tires: such as LHD (scraper) or underground transport trucks, resistant to high temperature, high humidity and compact space.

Open-pit mining tires: such as mining dump trucks, with high load capacity.

Mining wheels are widely used in mining operations, mainly supporting the following equipment: mining dump trucks, rigid dump trucks, underground mining, wheel loaders, graders, trailers, scrapers, drills, bulldozers and other models.

We can develop and produce rims of various sizes suitable for your vehicle according to your various needs.

Mining wheels are an important part of mining machinery, and are designed to meet the high load and long life requirements under extreme conditions. Choosing the right mining wheel and doing a good job of daily maintenance can not only improve the efficiency of mining operations, but also significantly reduce operating costs and equipment loss.

HYWG is China's first off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have more than 20 years of wheel manufacturing experience and a research and development team composed of senior engineers and technical experts. We focus on the research and application of innovative technologies and maintain a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use.

The 11.25-25/2.0 rims provided by our company for Sleipner-E50 mining trailer have been unanimously recognized by customers during use.

Sleipner E50 is an equipment transport system designed for mining, construction and heavy industry, especially for transporting large excavators and other heavy crawler machinery. It significantly reduces track wear, transportation time and operating costs by efficiently moving equipment from one work site to another.

The 11.25-25/2.0 rim developed and produced by our company is an industrial rim designed for heavy equipment such as Sleipner E50. Its specifications and structure make it suitable for mining equipment, construction machinery, loaders and other special machinery.

The design of this size rim has the following characteristics:

1. Robustness: designed to withstand heavy loads and harsh working environments.

2. Compatibility: suitable for tires of corresponding specifications (such as 17.5R25, 20.5R25, etc.) and mechanical equipment.

3. Multi-purpose: widely used in mining trailers, mining trucks, loaders, cranes and other construction machinery.

What are the advantages of using our 11.25-25/2.0 Rims For Sleipner-E50 Mining Trailers?

The main advantages of using 11.25-25/2.0 rims on the Sleipner E50 mining trailer are reflected in the following aspects:

1. High load-bearing capacity

The size of the 11.25-25 rim is suitable for 25-inch diameter tires and can withstand large loads. This is especially important for mining trailers like the Sleipner E50, which need to transport heavy equipment such as excavators, loaders, etc. Large rims can provide stronger support to ensure smooth movement of equipment on rugged or uneven ground.

2. Improved stability

The 2.0 offset design helps to optimize the geometry of the rim, so that it can better distribute the load, thereby improving the stability of the trailer. Especially when transporting heavy machinery, this design of the rim and tire can effectively prevent the equipment from tilting or becoming unstable during driving.

3. Reduced wear

The size and structural design of the rim can better distribute the pressure during transportation and reduce damage caused by improper wear of the tire or rim. This is crucial for mining trailers, because this type of trailer is used for a long time in harsh environments and has high friction.

4. Adapt to complex terrain

The mining environment is usually rugged, with complex terrain and road conditions. 11.25-25/2.0 rims can provide sufficient grip to help trailers better cope with complex road conditions. Larger rim diameter and width can ensure higher passability and avoid getting stuck in muddy or soft ground.

5. Increased durability

Large size and thick rim materials are generally more durable and can withstand long-term and intensive use. For the Sleipner E50 mining trailer, this means that the rims can withstand higher workloads during transportation, while being durable, reducing the frequency of rim replacement and maintenance costs.

6. Strong adaptability

The standardized size of the 11.25-25/2.0 rim makes it compatible with a variety of mining tires, providing flexible replacement and repair options. This is a clear advantage for operators of mining equipment and trailers, as different brands and models of tires can be used in different operating environments.

7. Optimize transportation efficiency

By improving the load-bearing capacity and stability of the rims and tires, the Sleipner E50 can complete the equipment transfer task in a shorter time. This greatly improves the working efficiency of the mining area, especially when the equipment needs to be frequently transferred, it can effectively reduce downtime.

8. High temperature resistance

The working environment in the mining area often has high temperatures and extreme conditions. The high-strength materials used in the 11.25-25/2.0 rims usually have good high temperature resistance and can maintain stable performance for a long time in these extreme environments.

Therefore, the application of the 11.25-25/2.0 rims in the Sleipner E50 mining trailer provides higher load-bearing capacity, stability, durability and adaptability, significantly improving the efficiency and reliability of the trailer in the transportation of heavy equipment, especially the ability to operate in the complex environment of the mining area.

.jpg)

We not only produce mining vehicle rims, but also have a wide range of applications in engineering machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Nov-28-2024