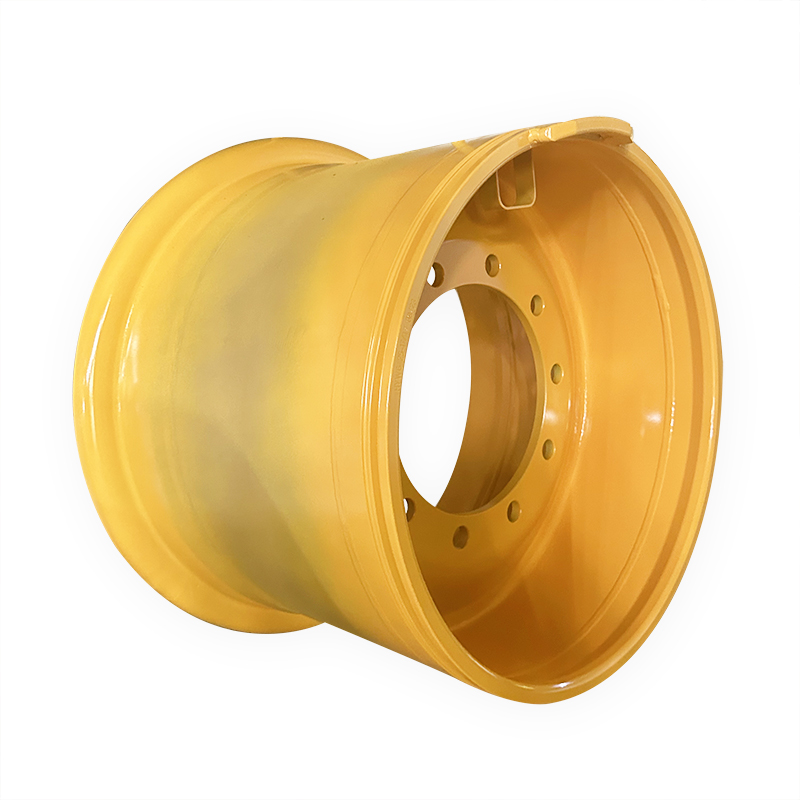

Wheel loader rims have different types depending on the working environment, tire type, and specific purpose of the loader. Choosing the right rim can improve the durability, stability, and safety of the equipment. The following are several common types of rims:

1. Single-piece rim

Features: Single-piece rims are made of a piece of steel and are the most common and basic rim structure.

Advantages: Simple structure, high strength, suitable for small and medium-sized wheel loaders.

Application scenarios: General construction sites, road construction, relatively flat mines, etc.

2. Multi-piece rims

Features: Multi-piece rims are composed of multiple steel sheets, and the rims can be split into different parts.

Advantages: When changing tires, it is convenient to disassemble and assemble, especially suitable for large tires and heavy-loaded vehicles. More suitable for working environments where tires need to be changed frequently.

Application scenarios: Large mines, quarries, heavy-load transportation, and other occasions where frequent tire changes or repairs are required.

3. Locking ring rim

Features: This type of rim usually includes a removable locking ring for fixing the tire.

Advantages: When removing the locking ring, it is not necessary to completely remove the entire tire, which is convenient and quick. Commonly used for fixing solid tires or reinforced tires.

Application scenarios: Used in operating situations that require higher stability and durability, such as mines, scrap metal recycling yards, etc.

4. Widened rim

Features: The width of this rim is larger than that of ordinary rims, suitable for the installation of wide tires or low-pressure wide tires.

Advantages: It can provide a larger contact area and reduce the pressure on the ground, especially suitable for soft ground or slippery environments.

Application scenarios: Used in sand, snow, muddy ground and other occasions where low ground pressure is required.

5. Reinforced rim

Features: Reinforced rims use thickened and reinforced materials, and are usually designed to cope with high-intensity and harsh working environments.

Advantages: Strong load-bearing capacity, good impact resistance and wear resistance, suitable for heavy-duty operations and work under extreme conditions.

Application scenarios: high-intensity working environments such as mines, quarries, and large construction sites.

6. Segmented rims

Features: The rim is divided into multiple independent parts, usually the outer ring, the lock ring, and the base rim.

Advantages: When changing tires, there is no need to disassemble the rim entirely, which is very suitable for large-size and heavy tires and easy to replace.

Application scenarios: Mostly used in wheel loaders for large mining equipment or heavy industrial equipment.

7. Aluminum alloy rims

Features: Made of aluminum alloy, light weight but high strength.

Advantages: Reduces the total weight of the vehicle, improves fuel efficiency, and improves the handling performance of the loader.

Application scenarios: Mostly used in working environments that require flexibility and fuel efficiency.

Choosing the right rim can not only enhance the working efficiency of the wheel loader, but also extend the service life of the tire and equipment. When working under high loads or complex environments, strength and durability are key considerations, while in ordinary construction or transportation, weight and fuel efficiency may be more important.

We are China's No. 1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have more than 20 years of experience in wheel manufacturing. We are widely involved in engineering machinery, mining vehicle rims, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

Our technology is very mature in the production and manufacturing of wheel loader rims. The following are some of the sizes we can produce

|

Wheel loader |

14.00-25 |

Wheel loader |

25.00-25 |

|

Wheel loader |

17.00-25 |

Wheel loader |

24.00-29 |

|

Wheel loader |

19.50-25 |

Wheel loader |

25.00-29 |

|

Wheel loader |

22.00-25 |

Wheel loader |

27.00-29 |

|

Wheel loader |

24.00-25 |

Wheel loader |

DW25x28 |

Why use wheel loaders? What are the advantages?

The reasons for using wheel loaders mainly include their unique advantages and applicability.

1. High maneuverability

Features: Wheel loaders can move quickly between work sites and usually have a high driving speed.

Advantages: Suitable for frequent changes of positions in a large work site, which can effectively improve work efficiency.

2. Adapt to a variety of terrains

Features: Although wheel loaders do not perform as well as crawler loaders on rugged terrain, they perform well on most flat or slightly uneven ground.

Advantages: Able to operate flexibly in different environments such as cities, construction sites, and quarries.

3. Reduce damage to the ground

Features: Compared with crawler equipment, wheel loaders have relatively low ground pressure and less damage to the ground.

Advantages: More advantages when working on easily damaged roads (such as asphalt and concrete), reducing damage to infrastructure.

4. Simple operation

Features: The cab design of wheel loaders is usually more comfortable, with a wide field of vision and intuitive operation.

Advantages: It is easy to train operators, improves work efficiency, and can reduce the occurrence of operating errors.

5. Versatility

Features: Multiple operating functions can be achieved by quickly replacing accessories (such as buckets, grippers, forklift arms, etc.).

Advantages: Multiple tasks such as shoveling, stacking, and handling can be completed on the same equipment, which improves the utilization rate of the equipment.

6. Economical

Features: The purchase cost and maintenance cost of wheel loaders are relatively low, especially when frequent movement is required.

Advantages: It can save fuel and maintenance costs in long-term operation, which is especially important for projects with limited budgets.

7. Convenient transportation

Features: Wheel loaders can drive to the work site by themselves, and no additional trailers are required for long-distance transportation.

Advantages: When operating in multiple locations, transportation costs and time are reduced, which improves efficiency.

8. Environmentally friendly

Features: Because it has little damage to the ground and relatively low noise and vibration, it is suitable for use in cities or places with strict environmental protection requirements.

Advantages: It can better meet modern environmental protection requirements and reduce the impact on the surrounding environment.

9. Lower failure rate

Features: Compared with crawler equipment, wheel loaders have a simpler mechanical structure and a relatively lower failure rate.

Advantages: Improves equipment reliability and reduces losses caused by unexpected downtime.

10. Suitable for a variety of operating fields

Features: Widely used in construction, mining, agriculture, waste treatment and other fields.

Advantages: Strong adaptability, able to meet the needs of different working conditions, and enhance the market value of equipment.

In summary, wheel loaders have become indispensable equipment in many industries with their flexible operability, efficient working capacity and economical use cost. Whether in construction, mining or agriculture, wheel loaders can effectively improve operating efficiency and reduce operating costs.

Our company is widely involved in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce for different fields:

Engineering machinery sizes: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 13.00-25, 14.00-25, 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Mining sizes: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-34, 15.00-35, 17.00-35, 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Forklift sizes are: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15, 6.50-15, 7.00 -15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Industrial vehicle sizes are: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5, 9.75x16.5, 16x17, 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28,

Agricultural machinery sizes are: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 11x18, W8x18, W9x18, 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x30, DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48.

Our products have world-class quality.

Post time: Oct-29-2024