The types of mining are mainly divided into the following four main types based on factors such as the burial depth of resources, geological conditions and mining technology:

1. Open-pit mining. The characteristic of open-pit mining is that it contacts mineral deposits on the surface or near the surface, and is mined by peeling off the covering rock and ore layer by layer. It is common in the mining of shallow mineral deposits such as coal, iron, copper and gold. Its advantages are high mechanization and low mining costs. Easy to transport and large-scale operation.

2. Underground mining. The characteristic of underground mining is that it targets deeply buried mineral deposits and enters the ore body through underground tunnels or slopes. It is widely used in the mining of metal mines (such as gold, silver, lead, zinc) and coal. Its advantages are less damage to the surface and reduced ecological impact. It can mine deeper resources.

3. Hydraulic mining. Hydraulic mining is mainly used to mine precious metals or ores (such as gold, tin, platinum) in river sediments. Minerals are flushed and screened by water flow. Its main advantage is that it has a small investment and is suitable for smaller ore bodies. It has high mining efficiency and is suitable for sedimentary deposits.

4. Leaching mining. The characteristic of leaching mining is to inject chemical solutions into the ore deposit, dissolve the minerals and then extract the liquid for separation and extraction. It is often used to mine salt, uranium and other mineral deposits. Its advantage is that it does not require surface excavation and reduces ecological damage. It is highly safe and suitable for difficult-to-mine ore bodies.

We have mature technology in the research and development and production of mining vehicle rims. We have extensive involvement in mining vehicles such as mining dump trucks, rigid dump trucks, underground mining vehicles, wheel loaders, graders, and mining trailers. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. You can send me the rim size you need, tell me your needs and troubles, and we will have a professional technical team to help you answer and realize your ideas.

The 29.00-25/3.5 rims provided by our company for Caterpillar underground mining vehicle CAT AD45 are currently undergoing vehicle testing and are about to be accepted. During this period, the test results of the rims have been recognized by customers.

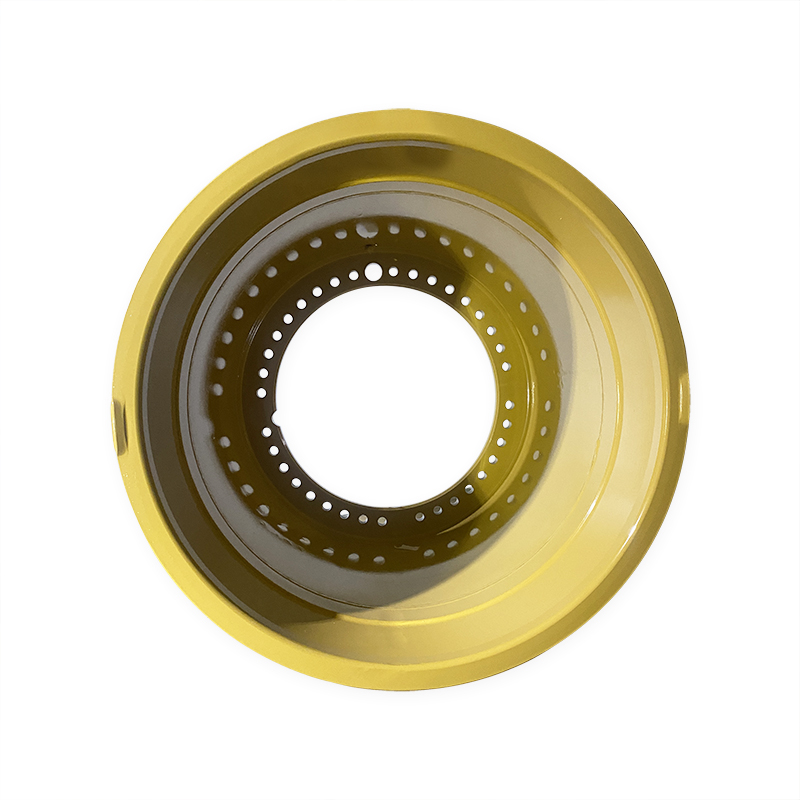

29.00-25-3.5 is a 5PC structure rim of TL tires. It is a high-performance rim designed for heavy machinery and mining vehicles (such as loaders, mining trucks, underground mining vehicles, etc.). It is matched with 29.00-25 tires and is widely used in harsh environments. It can withstand high loads and complex terrains and is an ideal choice for underground mining equipment.

Caterpillar AD45 is an efficient mining truck designed for underground mining, with high load capacity, strong power and excellent maneuverability. It is widely used in underground operating environments of metal mines, non-metallic mines and coal mines. It is compatible with the performance of our 29.00-25/3.5 rims.

What Are The Advantages Of 29.00-25/3.5 On Caterpillar Underground Mining Vehicle Cat Ad45?

When 29.00-25/3.5 rims are matched with matching tires and applied to Caterpillar underground mining vehicle AD45, they can provide multiple advantages for vehicles in the harsh working conditions of underground mines. This specification of tire is suitable for heavy loads, low speeds and harsh terrain conditions, and is one of the important configurations of heavy underground mining vehicles such as AD45.

1. High load-bearing capacity: This specification of tire has a large cross-sectional width and a strong carcass design, which can withstand the full load weight of AD45 (rated load 45 tons + dead weight), ensuring the stability of the vehicle during heavy-load transportation. The rim width (3.5 inches) design perfectly matches the carcass, increasing the structural strength of the tire and the uniformity of load distribution.

2. Superior impact resistance: The thickened sidewalls and high-quality rubber material of the tire can effectively absorb impact and reduce the vibration of the vehicle on uneven terrain. The working environment of underground mines often involves sharp rocks and potholes. This tire can effectively resist cutting, puncture and compression deformation. Reduce the risk of tire burst, improve operation safety and vehicle operation time.

3. Provide better traction: The large diameter and wide tread design of 29.00-25 enhance the contact area with the ground, and the tire pattern optimizes grip. Suitable for slippery, soft or rocky underground mine road conditions, providing stable traction. Ensure the climbing ability and stability of the vehicle in steep slope transportation, especially when fully loaded.

4. Wear resistance and long service life: The use of special wear-resistant rubber compounds and reinforced carcass can withstand high-frequency use and wear in harsh environments. The optimized tread design reduces irregular wear and extends tire life. Reduce replacement frequency and maintenance costs, and improve operational efficiency.

5. Improve vehicle stability and comfort: The wider tread and reasonable air pressure design can effectively disperse pressure and improve vehicle stability. Good shock absorption reduces the impact on the vehicle suspension and frame. The operator's comfort during long-term operation is improved, and the life of key vehicle components is extended.

6. Matching the high performance requirements of AD45: The power system and transmission design of Caterpillar AD45 match this specification of tire, which can achieve efficient power transmission and fuel economy. The tire specifications are perfectly matched to the vehicle axle load and working conditions. It enables the AD45 to perform optimal transportation performance when fully loaded and provide continuous and stable performance during operation.

The use of 29.00-25/3.5 tire specifications on Caterpillar AD45 has multiple advantages, including high load capacity, superior impact resistance, good traction and wear resistance. This tire specification can significantly improve the performance and operating efficiency of the vehicle in complex working conditions in underground mines, while reducing the cost of tire replacement and maintenance.

HYWG is China's No. 1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We not only produce mining vehicle rims, but also have a wide range of applications in engineering machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Dec-06-2024