What Are The Most Commonly Used Machines In Mining?

During the mining process, many different mechanical equipment are widely used in various operations. Each equipment has specific functions to help improve production efficiency, ensure safety and reduce costs. The following are the most commonly used types of machines in mining:

1. Mining haulage trucks, whose main function is to transport large quantities of ore, soil or other raw materials. Large mining trucks have strong load-bearing capacity and large tires, and can carry tens or even hundreds of tons of ore for transportation in harsh mining environments.

2. Excavators, whose main function is to dig soil, rocks and ores, and are usually used in open-pit mines. Mining excavators are usually equipped with large buckets, which can quickly and efficiently dig and load ore or soil into transport vehicles.

3. Loaders, which are mainly used to load materials such as ore, gravel, earthwork, etc., and transport them to other equipment or areas. Large wheel loaders have high loading capacity and flexibility, and can quickly load materials onto trucks or conveyor belts.

4. The function of crushers is to crush ore or rock to make it easier to transport or further process. After crushing, the ore can be reduced in volume, which facilitates subsequent processing processes (such as screening, extraction, etc.).

5. Drilling rigs, drilling holes for blasting operations, or mining operations in underground mines. These drills can quickly drill into the rock formation to create the necessary holes for blasting operations, or other mining operations.

6. Bulldozers are mainly used for pushing earth and leveling the ground. They are common in site leveling and waste cleaning in mining areas. Large bulldozers can complete tasks such as earth moving, road construction, and slope leveling in difficult mining environments.

7. Belt conveyor function: used to transport ore or other materials during mining, usually for ground and underground transportation. Belt conveyors can automatically transport materials in mines, greatly reducing the burden of manual operations and improving production efficiency.

8. Screening machine function: Screen the ore to separate unwanted materials (such as debris, undersized particles, etc.). These devices separate the ore into different particle sizes through vibration or rotation to adapt to subsequent processing or loading.

9. Underground mining equipment includes underground drills and underground load-carrying equipment, which are used for underground mining, usually for tunnel excavation and mine transportation.

10. The function of hydraulic breaker is to crush hard rocks or ores when needed, usually in conjunction with excavators. These devices can quickly break rock layers through high-frequency vibration and strong impact force, saving time and energy in the mining process.

In mining operations, different mechanical equipment is responsible for different tasks, from ore mining, crushing, transportation to processing, various equipment plays an important role. According to the specific needs of the mine, multiple machines are usually used for joint operations to achieve efficient and economical mining operations.

The most commonly used machines are divided into several categories according to their tasks, but mining transport trucks, excavators and loaders are indispensable key equipment.

These mining vehicles play an important role in mining operations and undertake the task of transporting ore, soil, waste and other heavy objects. In order to ensure that mining vehicles can operate efficiently and safely, their important accessories are essential.

Among them, tires and rims are the basis of mining transport vehicles, ensuring that vehicles can travel in harsh environments and carry large amounts of materials. The road surface in the mining environment is complex, hard and muddy, requiring tires to be resistant to high temperature, wear and tear, and able to withstand extremely high loads. Especially for equipment such as mining trucks and wheel loaders, they require high-strength wear resistance and load-bearing capacity.

HYWG is China's No. 1 off-road wheel designer and off-road wheel manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have more than 20 years of wheel manufacturing experience.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. Our rims not only involve a variety of vehicles, but are also the original rim suppliers in China for well-known brands such as Volvo, Caterpillar, Komatsu, Liebherr, and John Deere.

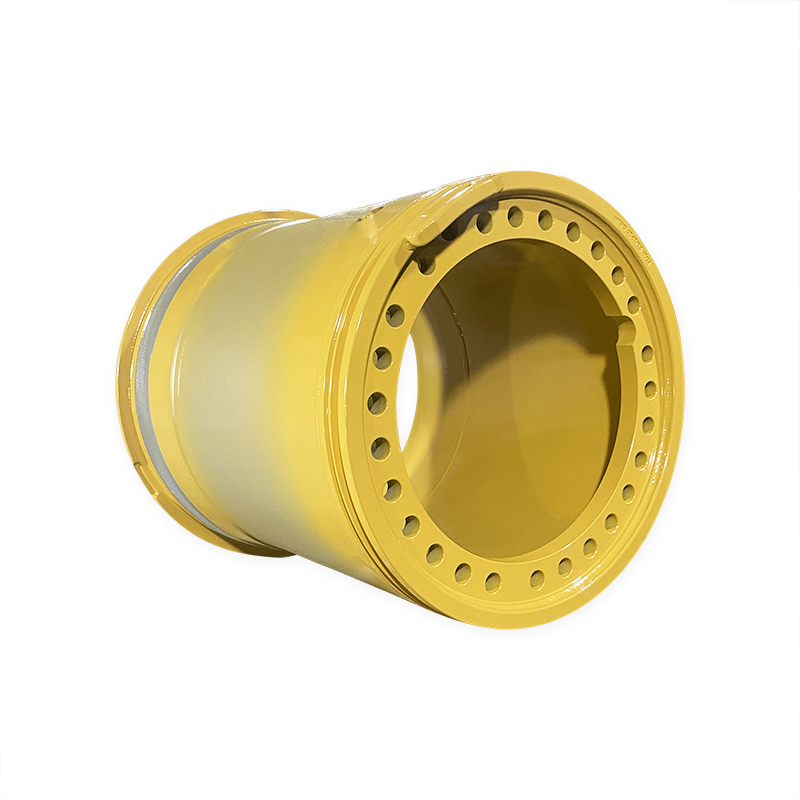

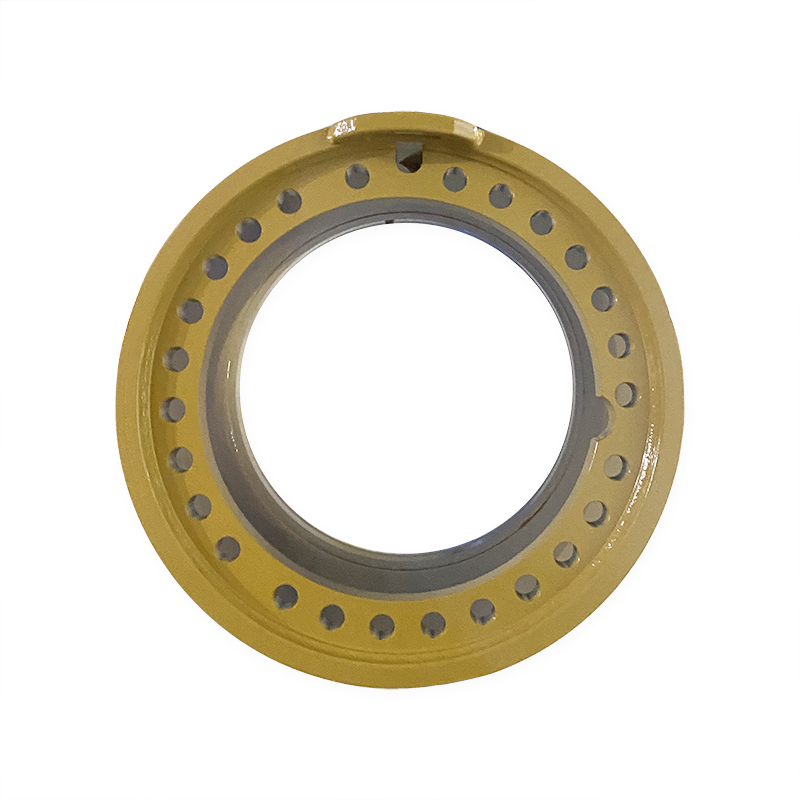

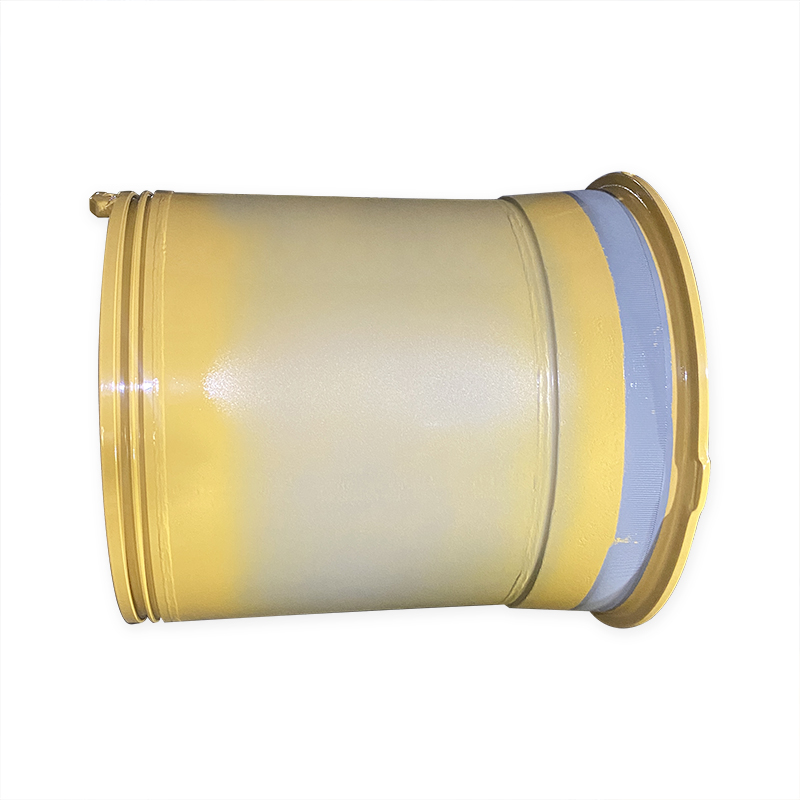

We have developed and produced suitable mining rims for Caterpillar mining wheel loaders CAT 980 G, with a size of 25.00-25/3.5.

1.jpg)

The 25.00-25/3.5 rim is a rim specification designed for heavy-duty construction machinery, and is widely used in wheel loaders, graders, mining trucks and other equipment. This rim is suitable for 29.5-25 tires and can meet the needs of heavy loads and complex working conditions. At the same time, it adopts a 5-piece structural design for easy installation and maintenance.

What are the advantages of Cat980 using the 25.00-25/3.5 rim provided by our company?

Cat980 wheel loaders are usually equipped with 25.00-25/3.5 rims, which are suitable for 29.5-25 tires. This configuration is widely used in heavy-duty construction machinery and has the following advantages:

1. Enhanced load-bearing capacity: The combination of 25.00-25/3.5 rims and 29.5-25 tires provides excellent load-bearing capacity and is suitable for equipment that requires high load capacity, such as Cat980.

2. Improved stability: The wide rims and tires increase the ground contact area, improving the stability and traction of the machine in various terrains.

3. Extended service life: The 25.00-25/3.5 rims made of high-strength steel have excellent durability and impact resistance and are suitable for harsh working environments.

4. Maintenance convenience: The three-piece or five-piece rim design makes tire installation and maintenance easier, reduces downtime, and improves work efficiency.

In general, the Cat980 loader uses the 25.00-25/3.5 rims produced by our company to improve the performance, stability and durability of the equipment and meet various heavy-duty operation needs.

We not only produce mining vehicle rims, but also have a wide range of applications in engineering machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Feb-28-2025