What are the types of rims for dump trucks?

There are mainly the following types of rims for dump trucks:

1. Steel Rims:

Features: Usually made of steel, high strength, durable, suitable for heavy-duty conditions. Commonly found in heavy-duty dump trucks.

Advantages: Relatively low price, strong impact resistance, easy to repair.

Disadvantages: Relatively heavy, not as beautiful as aluminum alloy.

2. Aluminum Rims:

Features: Made of aluminum alloy, light weight, more attractive appearance, good heat dissipation.

Advantages: Reduce the overall weight of the vehicle, improve fuel efficiency and handling performance.

Disadvantages: High price, may be easily damaged under extreme conditions.

3. Alloy Rims:

Features: Usually made of aluminum alloy or other metal materials, with good strength and lightweight characteristics.

Advantages: Relatively beautiful, suitable for high-performance dump trucks.

Disadvantages: High price, more complicated maintenance.

When choosing the rims for dump trucks, you need to consider the purpose of the vehicle, load capacity, and the requirements for weight, price and appearance.

Our company is widely involved in the rims of mining dump trucks. We are the first off-road wheel designer and manufacturer in China, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, etc. We can produce the following rims of different specifications and sizes for mining dump trucks:

|

Mining dump truck |

10.00-20 |

Rigid Dump truck |

15.00-35 |

|

Mining dump truck |

14.00-20 |

Rigid Dump truck |

|

|

Mining dump truck |

10.00-24 |

Rigid Dump truck |

19.50-49 |

|

Mining dump truck |

10.00-25 |

Rigid Dump truck |

24.00-51 |

|

Mining dump truck |

11.25-25 |

Rigid Dump truck |

40.00-51 |

|

Mining dump truck |

Rigid Dump truck |

29.00-57 |

|

|

Rigid Dump truck |

32.00-57 |

||

|

Rigid Dump truck |

41.00-63 |

||

|

Rigid Dump truck |

44.00-63 |

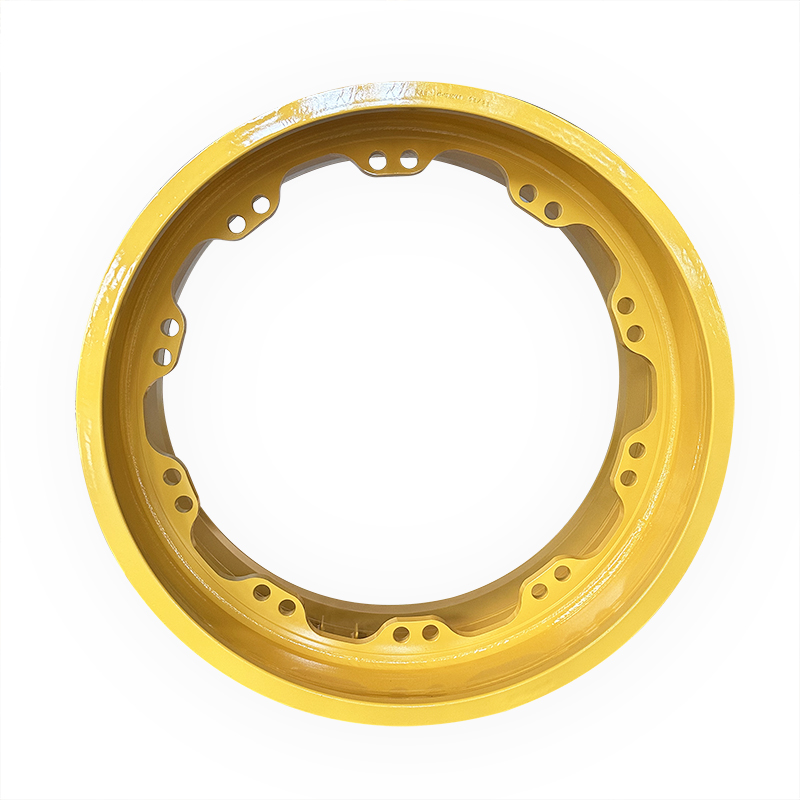

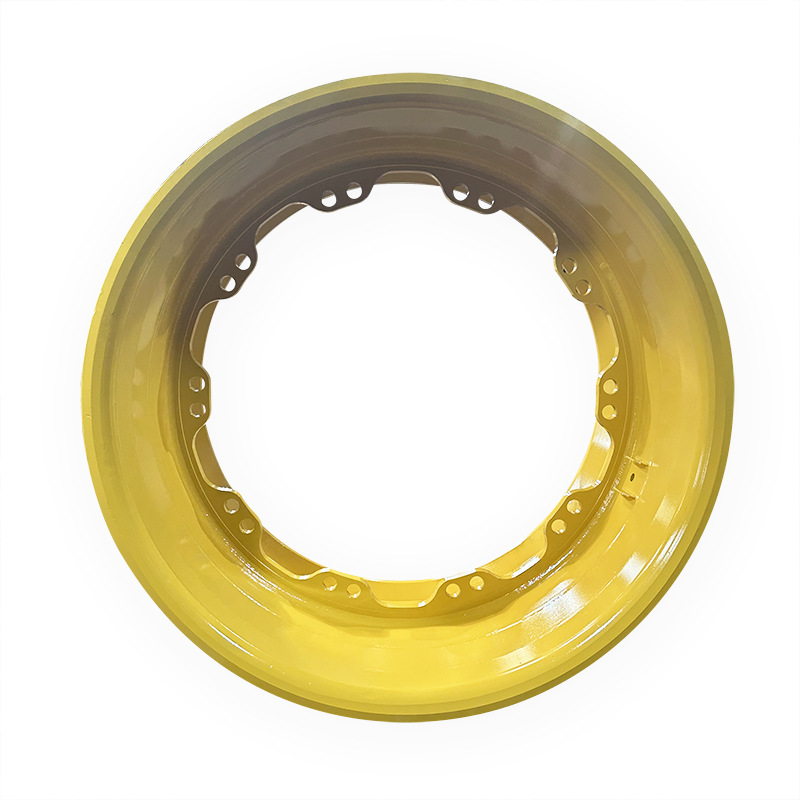

The five-piece rims we provide for Caterpillar 777 series mining dump trucks have been unanimously recognized by customers and have been put into mass production.

The 19.50-49/4.0 rim is a 5PC structure rim of TL tires, which is usually used for mining dump trucks.

The five-piece rims we provide for Caterpillar 777 series mining dump trucks have been unanimously recognized by customers and have been put into mass production.

The 19.50-49/4.0 rim is a 5PC structure rim of TL tires, which is usually used for mining dump trucks.

The logo of the 19.50-49/4.0 rim contains key information about its size and design. 19.50 represents the width of the rim in inches. That is, the width of this rim is 19.50 inches. 49 represents the diameter of the rim, also in inches. The diameter of this rim is 49 inches. 4.0 usually refers to the flange height or other specific structural parameters of the rim, and 4.0 represents its value, usually in inches.

Rims of this size are mainly used for mining trucks, dump trucks and other heavy machinery and equipment, especially in the mining and construction fields. This large-diameter rim can withstand extremely high loads and is suitable for vehicles equipped with giant tires. It adapts to uneven and rugged working environments and provides high load capacity and long service life.

What are the advantages of dump truck rims?

Dump truck rims have the following significant advantages, which make them perform well in heavy-duty transportation and harsh working conditions:

1. High load-bearing capacity

Dump trucks usually need to carry a large amount of cargo or heavy materials, so the rims are designed with extremely strong load-bearing capacity to support the trucks to drive safely under high load conditions. Steel rims are particularly durable and can withstand extremely high pressure and weight.

2. Strong durability

The rims of dump trucks are made of durable materials (such as steel or aluminum alloy), which have strong impact resistance and wear resistance. They can work for a long time in harsh environments such as rugged terrain, mining sites, construction sites, etc., reducing the risk of damage and maintenance frequency.

3. High strength torsion resistance

Since dump trucks often travel on uneven or bad roads, the rims must have strong anti-twisting ability. High-quality rims can maintain stable shape under these conditions, reduce deformation, and ensure safe driving of the vehicle.

4. Good heat dissipation performance

When dump trucks travel for a long time or operate with heavy loads, the braking system will generate a lot of heat. The design of the rim can help dissipate heat, especially aluminum alloy rims, whose good thermal conductivity helps cool the brakes, extend the service life of the brake system, and improve safety.

5. Reduce dead weight (improve fuel efficiency)

Using aluminum alloy or lightweight design rims can reduce the dead weight of the vehicle, thereby improving the fuel efficiency of the dump truck. This is especially important for dump trucks with long-distance transportation or frequent transportation tasks.

6. Easy maintenance

Some types of rims (such as split rims) are designed to be easy to remove and install, especially for working conditions where tires need to be replaced frequently. This design makes tire maintenance and replacement more efficient and reduces downtime.

7. Improve safety

High-quality rims not only have strong load-bearing capacity, but also maintain good operating conditions under extreme load and high pressure conditions, reduce the risk of tire damage, blowout or falling off, and ensure driving safety, especially in heavy-duty operating environments.

8. Adapt to a variety of harsh working conditions

Dump trucks usually work in complex terrain and harsh weather conditions, such as quarries, mines, construction sites, etc. The rim design can cope with these extreme environments, with corrosion resistance, impact resistance and other characteristics, extending service life and improving work efficiency.

9. Enhance vehicle stability

The sturdy design and good matching of the rim help maintain the balance and stability of the vehicle, especially when encountering inclined and rugged ground during transportation. This can effectively reduce the risk of overturning and rollover.

Through these advantages, dump truck rims not only improve the performance of the vehicle, but also greatly improve the safety, economy and work efficiency of operations.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce for different fields:

Engineering machinery sizes: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 13.00-25, 14.00-25, 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Mining sizes: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-34, 15.00-35, 17.00-35, 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Forklift sizes are: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15, 6.50-15, 7.00 -15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Industrial vehicle sizes are: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5, 9.75x16.5, 16x17, 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28

Agricultural machinery sizes are: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 11x18, W8x18, W9x18, 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x30, DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Our products have world quality.

Post time: Oct-16-2024