In engineering equipment, the rim mainly refers to the metal ring part where the tire is mounted. It plays a key role in various engineering machinery (such as bulldozers, excavators, tractors, etc.). The following are the main uses of the rims of engineering equipment:

1. Support tires:

Fix the tire: The rim provides a firm platform to fix the tire, ensuring that the tire remains stable during the operation of the equipment.

Carrying weight: The rim must be able to withstand the weight of the equipment as well as the pressure and impact generated during operation.

2. Transmit power:

Rotation transmission: The rim transmits power from the engine or motor to the tire, allowing the equipment to move and operate.

Torque transmission In engineering equipment that requires high torque, the design of the rim must be able to effectively transmit and distribute torque.

3. Maintain tire shape:

Structural integrity: The rim helps maintain the round structure of the tire and prevents the tire from deforming under load, thereby ensuring the smooth operation of the equipment.

Airtightness: In tubeless tires (radial tires), the design of the rim must also ensure good airtightness to prevent air leakage.

4. Adapt to different terrains:

Versatile design: Engineering equipment often needs to work in a variety of terrain conditions, and the rim design needs to adapt to these environments, including mud, sand, rocks, and uneven ground.

Slip resistance: Some rims are designed with special surface textures or structures to provide better anti-slip performance and increase the grip of the equipment in harsh conditions.

5. Maintenance and replacement:

Easy to disassemble and assemble: The design of the rim needs to take into account the convenience of maintenance and replacement, so that the tire can be quickly replaced when it is damaged or worn.

Durability: Since engineering equipment usually works in harsh environments, the rim material must have high durability and impact resistance to reduce the frequency and cost of maintenance.

6. Safety:

Protective function: The rim can also be designed with a protective device to prevent the tire from being punctured or damaged by sharp objects, improving the safety of the equipment.

Stability: By providing stable support, the rim helps prevent the equipment from tilting or tipping over during operation.

The rim of engineering equipment plays a vital role in the safety, efficiency and reliability of equipment operation.

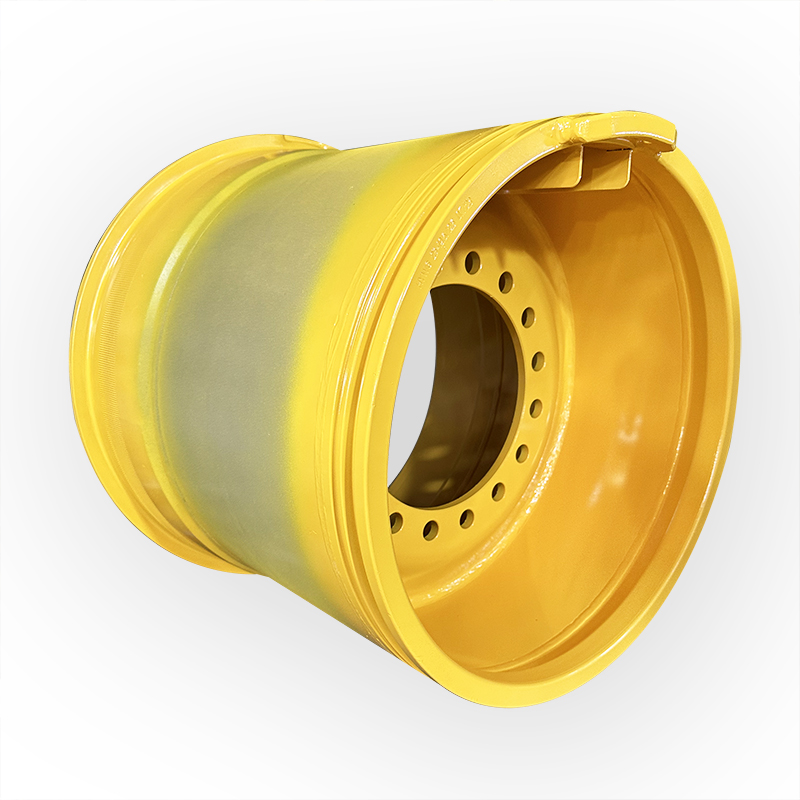

We are the supplier of 19.50-25/2.5 rims for Volvo construction equipment wheel loaders. 19.50-25/2.5 is a TL tire 5PC structure rim, commonly used for wheel loaders, such as Volvo L90, L120, CAT930, CAT950. The following link is a detailed introduction to the Volvo 19.50-25/2.5 size rims produced by our company:

What are the main advantages of wheel loaders in engineering equipment?

Mainly reflected in the following aspects:

1. Flexibility and maneuverability

Small turning radius: Wheel loaders have a small turning radius and can operate flexibly in a small space and adapt to different working environments.

High-speed movement: Compared with crawler loaders, wheel loaders can move at a higher speed inside and outside the construction site, reducing non-productive time and improving work efficiency.

2. Versatility

Multiple attachments: Wheel loaders can be equipped with a variety of work attachments, such as buckets, forklifts, grabs, snowplows, etc., to meet various operating needs, including loading, handling, digging, leveling and sweeping.

Quick change: The quick change system of the attachment makes the operation conversion more convenient, further improving the versatility of the equipment.

3. Operation comfort

Ergonomic design: The cab design of modern wheel loaders focuses on the comfort of the operator, equipped with comfortable seats, good vision, advanced control panels and air conditioning systems to reduce operator fatigue.

Automated control: Equipped with intelligent control systems such as automatic transmissions and remote monitoring systems, it improves the simplicity and accuracy of operation.

4. Ease of maintenance

Easy maintenance: The structural design of wheel loaders makes maintenance and maintenance easier, reducing downtime and maintenance costs.

Extensive service network: Manufacturers usually provide comprehensive after-sales service and support, including regular maintenance, original parts supply and technical training to ensure long-term reliable operation of the equipment.

5. Economic Benefits

Fuel Efficiency: Modern wheel loaders use efficient engines and hydraulic systems to provide higher fuel efficiency and reduce operating costs.

High Productivity: Due to their fast mobility and versatility, wheel loaders perform well in various operations and significantly improve productivity.

6. Strong Adaptability

Multiple Operating Environments: Wheel loaders are able to work in various terrain conditions, including mud, gravel, snow and uneven ground, and have strong adaptability.

Wide Application: Suitable for construction sites, mines, ports, agriculture and industry and other fields, with a wide range of application scenarios.

7. Environmental Performance

Low Emission Engine: Modern wheel loaders are usually equipped with low emission engines that meet environmental standards to reduce the impact on the environment.

Noise Control: Advanced noise reduction technology is used to reduce the noise level of the equipment during operation and improve the working environment.

Wheel loaders have become an indispensable and important tool in engineering equipment due to their flexibility, versatility, operating comfort, easy maintenance, economic benefits, strong adaptability and environmental performance.

The following are the sizes of wheel loaders we can produce.

Post time: Aug-07-2024