What Are Mining Wheel Tires?

The uses of industrial wheels are mainly reflected in various industrial fields, including logistics, construction, mining, manufacturing, etc. Industrial wheels refer to wheels specially used on industrial machinery, equipment and vehicles, with high load-bearing capacity, strong wear resistance, and adaptability to complex working conditions.

The specific uses are as follows:

1. In logistics and warehousing

Forklift: used to carry goods and improve warehousing and loading and unloading efficiency.

Pallet trucks and trolleys: used for short-distance transportation, convenient and flexible.

Conveying equipment assists in cargo transportation in automated warehouses or production lines.

2. In construction and engineering machinery

Wheel loaders: used for earthworks, building construction, road construction, etc.

Bulldozers and graders: provide traction in harsh terrain and improve construction efficiency.

Articulated trucks: transport heavy objects such as ore, sand and gravel in rugged terrain.

3. In the mining industry

Mining dump trucks (rigid/articulated): used to transport heavy materials such as ore and coal.

Underground transportation equipment: suitable for underground mine transportation, ensuring high load capacity and wear resistance.

Drilling equipment: requires wheels that are resistant to high pressure and impact to cope with extreme working conditions.

4. In agricultural machinery

Tractor: provides greater traction and adapts to soft ground in farmland.

Harvester, seeding machine: requires high durability and anti-skid properties to ensure stable operation.

The core function of industrial wheels is to carry weight, provide traction, improve mobility efficiency, and adapt to various complex working conditions. It is widely used in logistics, construction, mining, agriculture and other fields.

We are China's first off-road wheel design and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for Volvo, Caterpillar, Liebherr, John Deere and other well-known brands.

We are deeply involved in the production and manufacturing of industrial rims. The 19.50-25/2.5 rims provided by our company for LÄNNEN backhoe loaders have won unanimous recognition from customers in the work.

LÄNNEN is a Finnish construction machinery manufacturer, famous for its versatile backhoe loaders, suitable for municipal engineering, forestry, railway maintenance and infrastructure construction. LÄNNEN backhoe loaders are versatile and highly maneuverable equipment that need to be equipped with high-strength and durable rims to ensure stability and reliability under complex working conditions.

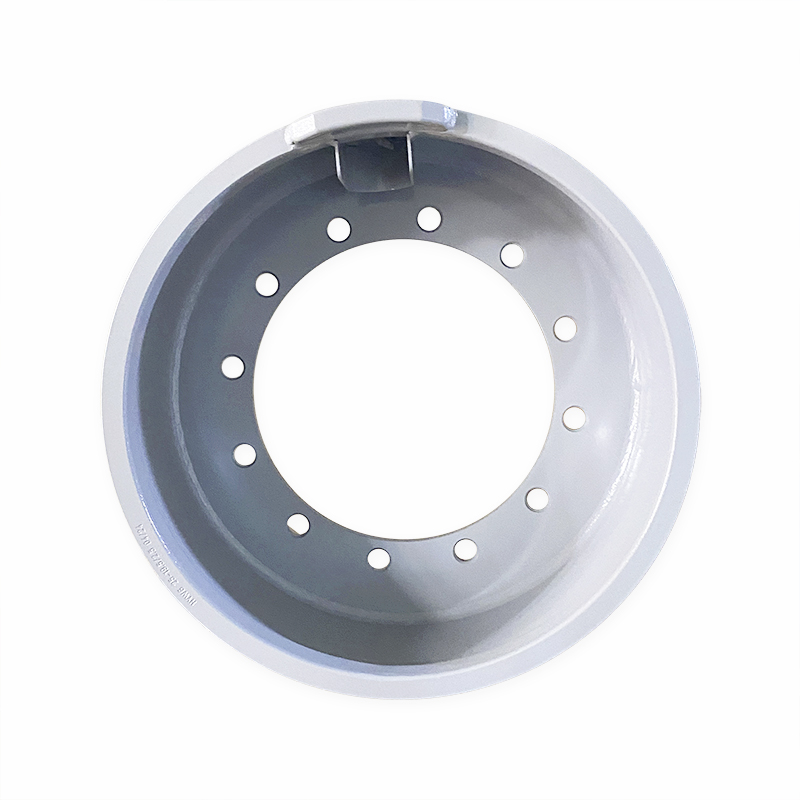

1.jpg)

For this reason, we designed a suitable rim based on the characteristics of the LÄNNEN backhoe loader.

What are the characteristics of the 19.50-25/2.5 rim for backhoe loaders?

The core features of the rims for backhoe loaders are as follows

1. High-strength material, impact resistance

The use of high-strength steel ensures that the rims are not easily deformed or cracked under heavy loads and harsh terrain.

Applicable to rugged construction sites, such as railway maintenance, forest operations, muddy roads, etc.

2. Wear-resistant and corrosion-resistant, long service life

The surface is treated with an anti-corrosion coating (such as spraying, electroplating), which can effectively prevent rust and oxidation and increase the service life of the rim.

Applicable to a variety of working conditions such as wetlands, muddy environments, municipal construction areas, etc.

3. Strengthened design, large load-bearing capacity

The thickened rim structure is used to improve the overall load-bearing capacity to meet the high-load operation requirements of backhoe loaders.

It can be matched with engineering tires with high load-bearing capacity (such as solid tires and pneumatic tires) to enhance the stability of the whole machine.

4. Wide adaptability

It can support quick-release design, which is convenient for tire replacement and repair, and improves maintenance efficiency.

5. Compatible with a variety of tires to adapt to different working conditions

It can be matched with pneumatic tires (such as all-terrain tires) to improve comfort and off-road capability.

It can be matched with solid tires, suitable for high loads and harsh environments, and reduce the risk of tire blowouts.

It is suitable for common rim sizes of backhoe loaders.

19.50-25/2.5 rims, suitable for harsh terrain, high strength and impact resistance.

The rims of backhoe loaders need to have the characteristics of high strength, corrosion resistance, strong load-bearing, and easy maintenance to ensure the stable operation of the equipment under various complex working conditions!

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Mar-10-2025