What Are The Uses Of Kalmar Container Handlers?

Kalmar container handlers are the world's leading port and logistics equipment manufacturer. Kalmar's mechanical equipment specially designed for container handling is widely used in ports, docks, freight stations and container yards. It is mainly used to handle and transport containers, and is used for tasks such as cargo transshipment in container yards, sea and land transportation. Kalmar container handlers are of various types, mainly including empty container handlers, loaded container handlers and reach stackers, which complete the handling, stacking and loading and unloading of containers according to different operating requirements.

Main types and uses of Kalmar container handlers:

1. Empty container handler:

Use: Specially used for handling and stacking empty containers. Suitable for container yards that need to handle a large number of empty containers quickly and efficiently.

Features: Strong stacking capacity, can stack 8-9 layers of containers vertically, and has excellent operating vision, which improves work efficiency and safety.

2. Loaded Container Handler:

Purpose: Mainly used to handle heavy containers filled with goods, suitable for places with high demand for container transportation such as docks and ports.

Features: Strong stacking capacity, capable of handling heavy containers weighing about 40 tons. Strong power, suitable for high-intensity working environment.

3. Reach Stacker:

Purpose: Used to handle, stack and transfer heavy and empty containers, with extremely high flexibility, suitable for handling container yards with different discharge methods.

Features: It can flexibly handle multiple rows of containers and can stack containers to more than 5 layers. It can be flexibly operated in a small space and is one of the commonly used handling equipment in container terminals.

4. Automated and intelligent equipment:

Kalmar also provides automated container handling solutions, which improve efficiency and reduce labor costs through autonomous driving and remote control technology. Intelligent management systems help monitor equipment performance and optimize operating processes.

Advantages of Kalmar container handlers:

Efficient performance: Kalmar container handlers are known for their high performance and efficient operation, and can cope with high-intensity container handling tasks.

Durability and reliability: The equipment has a sturdy structure and is suitable for harsh operating environments, with low maintenance costs for long-term use.

Safety: It integrates a variety of safety systems, including advanced stability control and all-round vision for operators, to ensure safe handling operations.

Environmentally friendly design: Kalmar's hybrid and electric container handlers can reduce carbon emissions and meet the environmental protection requirements of modern ports.

Kalmar container handlers are widely used in major ports and logistics centers around the world. They are important equipment in the field of container handling and are widely recognized by the industry for their high efficiency, stability and intelligence.

We are China's No. 1 off-road wheel designer and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have more than 20 years of wheel manufacturing experience. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

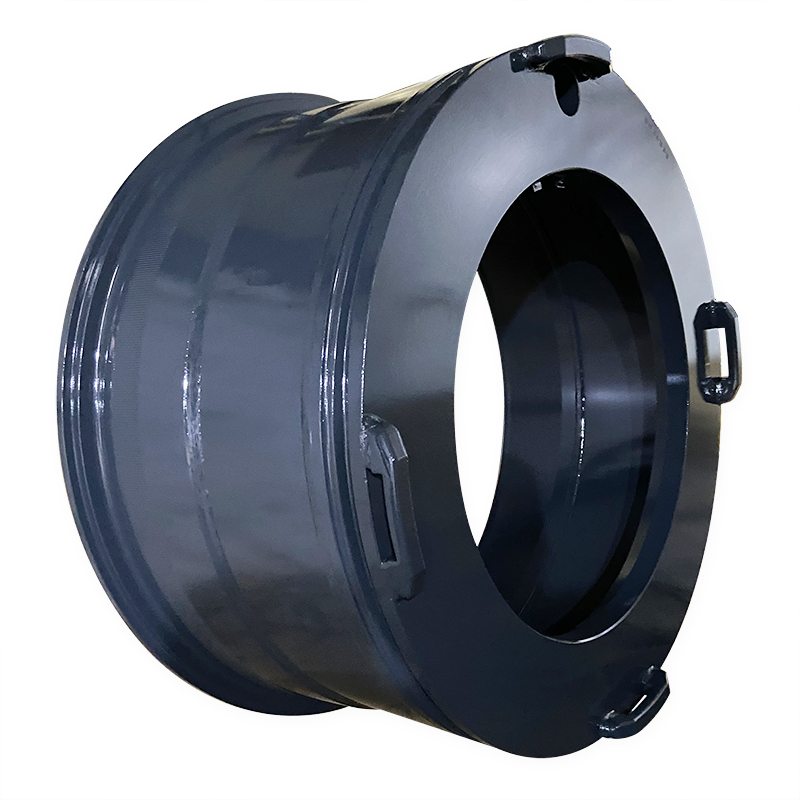

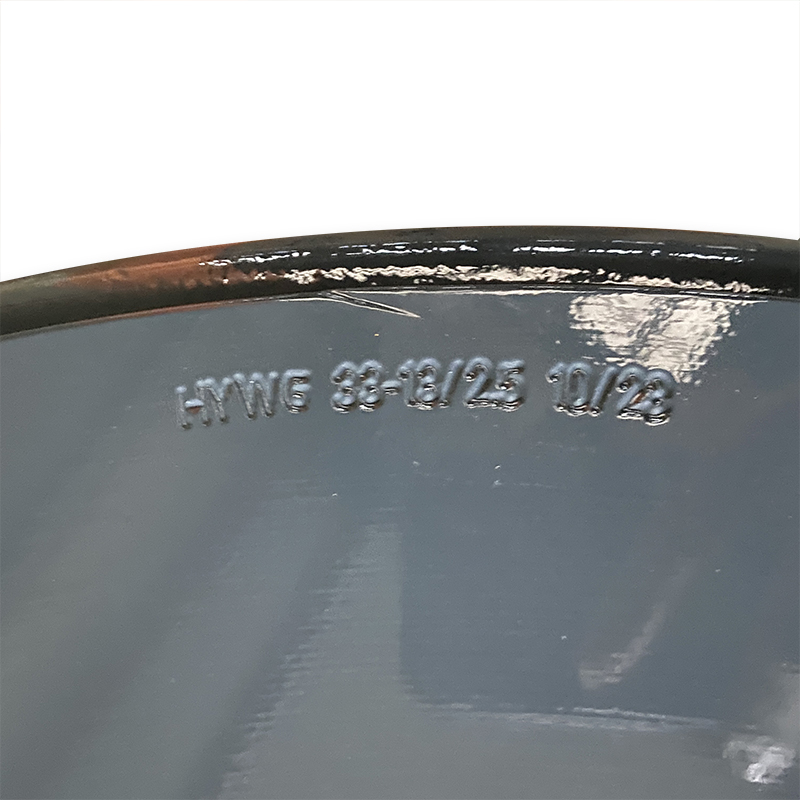

The 13.00-33/2.5 rims provided by our company for Kalmar have been highly recognized by customers. 13.00-33/2.5 is a 5PC structure rim of TL tires, commonly used in container loaders and unloaders.

“13.00-33/2.5” is a tire specification representation for heavy vehicles or mechanical equipment, usually used for large, heavy-duty equipment, such as container handlers in ports, heavy trucks for mines, and other mechanical equipment that requires high load and high-intensity operation.

Tire specification explanation:

13.00: Indicates the cross-sectional width of the tire in inches. The width of the tire is 13 inches.

33: Indicates the diameter of the rim, also in inches. The diameter of the rim that the tire is suitable for is 33 inches.

/2.5: Usually refers to the width of the rim.

What should I pay attention to when operating a container loader?

Operating a container loader is a job that requires high technical and safety requirements. When carrying out container loading and unloading operations at ports, terminals or logistics centers, special attention must be paid to the following points to ensure the safety of equipment, goods and personnel:

1. Preparation before operation

Equipment inspection: Before operation, the equipment should be fully inspected to ensure that the brake system, hydraulic system, tires, boom, transmission, etc. are in good working condition.

Fuel/power inspection: Check the oil level or battery power to ensure that the container handler has enough energy to complete the task.

Safety equipment inspection: Confirm that safety facilities such as the operator's seat, seat belts, vision mirrors, lighting systems and sound alarm devices are working properly.

Operation area inspection: Ensure that there are no obstacles in the work area, the ground is flat, and no personnel or unnecessary equipment stays in the operation path.

2. Safety precautions during operation

Smooth operation: When loading and unloading containers, keep the equipment moving smoothly, avoid sudden stops or sudden turns, and prevent the container from shaking or tipping over.

Load limit: Strictly abide by the load limit of the equipment and avoid overloading operations. Overloading will not only damage the equipment, but may also cause safety accidents.

Proper lifting of containers: Ensure that the locking mechanism of the lifting equipment and the container is firm and correct to ensure that the container will not slip during handling.

Comply with stacking height limits: Different loading and unloading equipment has different stacking capacities. When operating, ensure that the stacking height of the container does not exceed the safety range of the equipment.

Ensure good vision: The operator should ensure that there are no obstacles in the operating area and around the equipment to ensure a clear view. If the line of sight is blocked, an assistant or monitoring device should be used to assist the operation.

3. Personnel safety

Wear safety equipment: Operators and ground staff should wear necessary protective equipment such as protective helmets, reflective vests, and safety boots.

Keep a safe distance: Other staff should stay away from the equipment being operated, especially during container loading, unloading or stacking, to avoid collisions or other accidents.

Use communication tools: In busy ports or yards, operators should maintain good communication with ground commanders to ensure that loading and unloading work is coordinated correctly.

4. Precautions for special weather conditions

Strong wind weather: In strong wind conditions, loading and unloading containers is particularly dangerous, especially when stacking at high altitudes, the containers may tilt or slide due to wind force. At this time, the operation should be stopped or the stacking height should be lowered.

Bad weather: In weather conditions such as heavy rain and heavy snow, the line of sight is blocked or the ground is slippery, and special care should be taken to operate, and the operation should be suspended if necessary.

5. Equipment Care and Maintenance

Regular maintenance: Regularly maintain the equipment to ensure that all functions of the equipment are normal and reduce safety hazards caused by equipment failure.

Record operation: The operator should record the use, problems and maintenance records of each equipment so that the equipment can be inspected and maintained in time.

6. Emergency plan

Handling emergencies: The operator should be familiar with the emergency stop button of the equipment and the relevant emergency operation procedures to ensure that they can respond quickly and safely in emergencies.

Emergency evacuation route: Clear emergency evacuation channels and emergency assembly points should be set up in the working area to ensure rapid evacuation in the event of an accident.

We can also produce the following rims of different specifications and sizes in container loaders:

|

Container handler |

11.25-25 |

|

Container handler |

13.00-25 |

|

Container handler |

13.00-33 |

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce for different fields:

Engineering machinery sizes: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 13.00-25, 14.00-25, 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Mining sizes: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-34, 15.00-35, 17.00-35, 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Forklift sizes are: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15, 6.50-15, 7.00 -15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Industrial vehicle sizes are: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5, 9.75x16.5, 16x17, 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28

Agricultural machinery sizes are: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 11x18, W8x18, W9x18, 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x30, DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Our products have world quality.

Post time: Oct-10-2024