What does TPMS mean for construction vehicle tires?

TPMS (Tire Pressure Monitoring System) for construction vehicle tires is a system that monitors tire pressure and temperature in real time, which is used to improve vehicle safety, reduce the risk of tire damage, and improve fuel efficiency. TPMS is particularly important on heavy equipment and construction vehicles (such as mining trucks, excavators, loaders, etc.) because these vehicles often operate under extreme conditions and the performance of tires is critical to safety and operating efficiency.

Functions and roles of TPMS:

1. Real-time monitoring of tire pressure:

- The TPMS system continuously monitors the air pressure in the tire through sensors installed on each tire. If the air pressure is lower or higher than the preset standard value, the system will issue a warning to remind the driver to take action.

- This helps to avoid tire blowouts and excessive wear caused by low tire pressure, or reduced grip and tire overheating caused by high tire pressure.

2. Real-time monitoring of tire temperature:

- In addition to air pressure, TPMS also monitors tire temperature. When construction vehicles are working for a long time or driving under high temperature and harsh road conditions, tires are prone to overheating, increasing the risk of failure. Temperature monitoring can help operators detect potential problems in advance and prevent tire failures or fire accidents.

3. Improve fuel efficiency:

- Low tire pressure will increase the rolling resistance of the tire, resulting in increased fuel consumption. The TPMS system can help ensure that the tire is always in the optimal pressure range, thereby reducing fuel consumption and improving the economy of the vehicle.

4. Extend tire life:

- By maintaining the correct tire pressure and monitoring tire temperature, TPMS can significantly reduce tire wear and extend tire life, thereby reducing the frequency of tire replacement and reducing maintenance costs.

5. Improve safety:

- When engineering vehicles are operating in harsh environments, problems with tires may cause equipment to lose control or even cause serious safety accidents. TPMS can detect problems early, prevent potential dangers, and ensure operational safety.

How TPMS works:

The TPMS system usually consists of sensors installed in the tire, a central control module, and a display device. The sensor measures the air pressure and temperature in the tire and transmits the data to the driver's display or warning system via wireless signals. If the air pressure or temperature exceeds the normal range, the system will issue a warning to allow the operator to take timely measures.

Importance of TPMS in construction vehicles:

Construction vehicles usually work under heavy loads, complex terrain and harsh weather conditions, and tire pressure and temperature management is critical. The TPMS system can help operators better monitor tire status and reduce the risk of unexpected downtime, tire damage or safety accidents, especially in mines, construction sites and other places where equipment operation is extremely demanding.

In summary, TPMS plays a vital role in construction vehicle tire management, helping to improve safety, optimize performance and reduce operating costs.

Construction vehicle tires and construction vehicle wheel rims are important components of construction vehicles, carrying heavy loads and adapting to complex working conditions.

We are China's No. 1 off-road wheel designer and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards, and we have more than 20 years of wheel manufacturing experience. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

Our company is widely involved in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

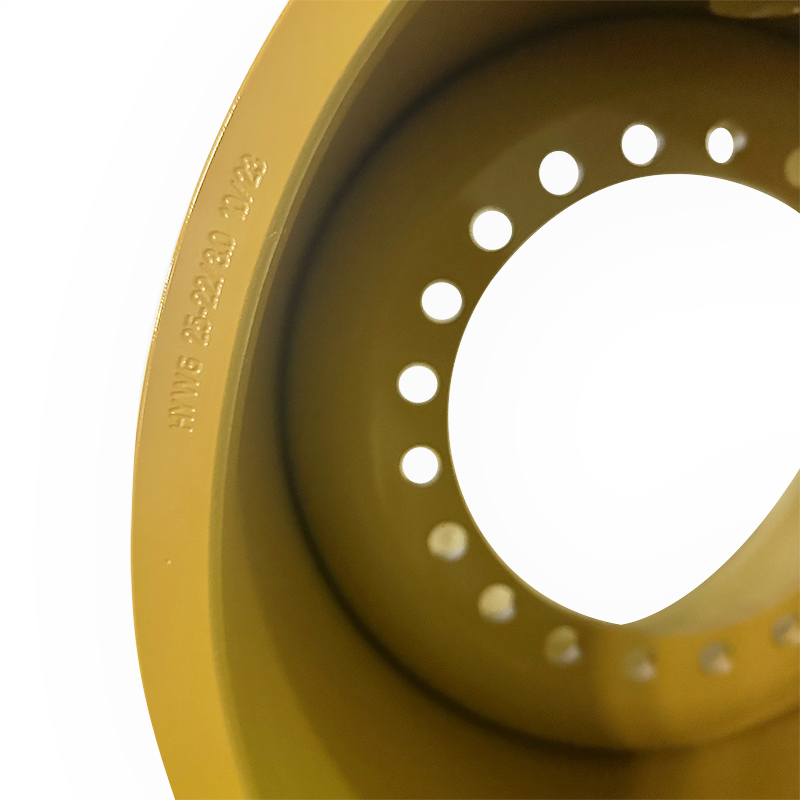

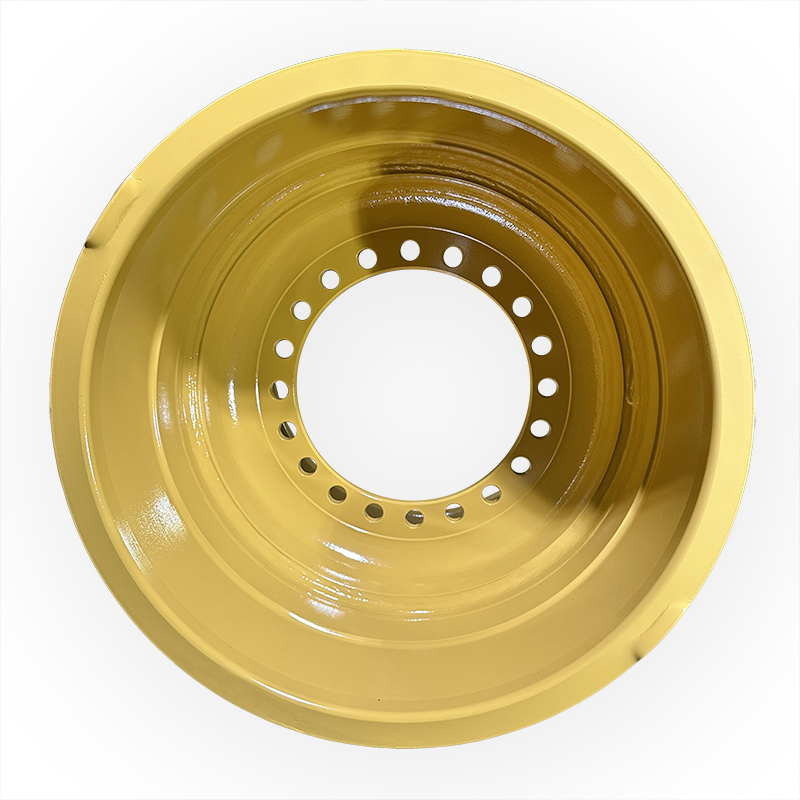

The 22.00-25/3.0 rims we provided to Caterpillar for use on wheel loaders for construction vehicles have been unanimously recognized by customers.

“22.00-25/3.0” is a way of indicating tire specifications and rim sizes, which is usually used in heavy equipment such as large construction machinery, mining trucks, loaders, etc. The specific explanation is as follows:

1.22.00: Indicates the width of the tire in inches. This means that the cross-sectional width of the tire is 22 inches.

2. 25: Indicates the diameter of the rim (wheel hub), also in inches. This means that the diameter of the rim that the tire is suitable for is 25 inches.

3. /3.0: This value usually indicates the width of the rim in inches. 3.0 means that the width of the rim is 3 inches. This part is the structural size of the tire installed on the rim, ensuring that the tire and rim can match.

This specification of tires and rims are usually used for large construction machinery, such as loaders, bulldozers, mining trucks, container handlers, etc., because these mechanical equipment require high loads and powerful tires to cope with complex working environments.

Main features:

High load capacity: wide tires and large rims can withstand high weights and are suitable for heavy-duty operations.

Strong wear resistance: tires of this specification are usually used in harsh environments and have strong wear resistance and impact resistance.

Good stability: large diameter and wide tires provide a good contact area and can maintain stability on loose or rugged ground.

This tire and rim combination usually provides reliable support for heavy vehicles, ensuring safety and performance stability under harsh working conditions.

Why Do Wheel Loaders Use Solid Tires?

Wheel loaders use solid tires in some special occasions, mainly to cope with harsh working environments and harsh working conditions. The specific reasons include the following aspects:

1. Strong puncture resistance

Complex working environment: Wheel loaders usually work in construction sites, mines, waste disposal sites and other environments. There may be a large number of sharp stones, steel bars, broken glass, etc. on the ground in these places, which can easily puncture ordinary pneumatic tires.

Solid tires have no inner cavity: Since solid tires have no inflatable structure and are completely filled with rubber inside, they will not leak or burst due to puncture like pneumatic tires, thus greatly reducing the downtime and maintenance costs caused by tire damage.

2. Wear resistance and long service life

High-intensity operation: Wheel loaders usually require long-term and high-intensity operation, and tires will be subjected to a lot of friction and wear. Solid tires have a higher wear resistance than ordinary pneumatic tires due to their high material density, so they have a longer service life under harsh conditions.

3. Maintenance-free

No need for frequent inflation or repair: Solid tires eliminate the trouble of tire inflation, tire pressure detection and repair. For occasions that require continuous operation, the use of solid tires can greatly reduce the downtime caused by tire problems, thereby improving production efficiency.

4. Strong heavy-load capacity

Withstands large loads: Wheel loaders often need to carry and transport heavy materials. Solid tires have a stronger load-bearing capacity than pneumatic tires and are not easily deformed or damaged due to overloading. They are particularly suitable for occasions where heavy objects need to be transported frequently.

5. Good stability

Stronger anti-seismic performance: Solid tires have a sturdy structure and uniform force. When transporting heavy objects, they will not have large elastic deformation like pneumatic tires, so they can provide a more stable driving experience, especially on rugged ground.

6. Suitable for low-speed and short-distance operations

The use of solid tires by wheel loaders in extreme working environments can significantly improve their reliability, durability and safety, and reduce tire maintenance costs. Solid tires are an ideal choice under high-risk, high-load, and low-speed operating conditions.

The following are the various sizes of rims that our company can produce for different fields:

Engineering machinery sizes: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 13.00-25, 14.00-25, 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Mining sizes: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-34, 15.00-35, 17.00-35, 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Forklift sizes are: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15, 6.50-15, 7.00 -15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Industrial vehicle sizes are: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5, 9.75x16.5, 16x17, 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28

Agricultural machinery sizes are: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 11x18, W8x18, W9x18, 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x30, DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Our products have world quality.

Post time: Oct-10-2024