What Is a Steel Rim?

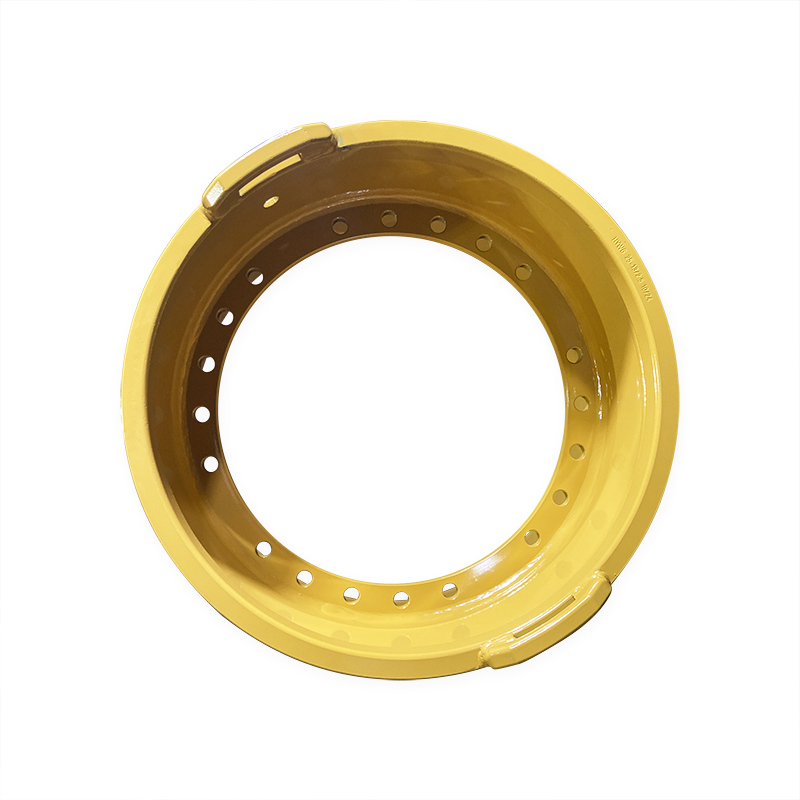

A steel rim is a rim made of steel material. It is made by using steel (i.e. steel with a specific cross-section, such as channel steel, angle steel, etc.) or ordinary steel plate through stamping, welding and other processes. The steel rim is usually located on the outside of the rim. Its main function is to provide support and fix the tire and bear a large load. It is suitable for occasions where it bears heavy objects.

It is usually used on various heavy vehicles and industrial equipment such as engineering machinery, mining vehicles, construction equipment, etc. Compared with traditional cast steel rims and forged rims, the manufacturing process and material properties of steel rims determine its different advantages in strength, durability and cost.

HYWG is China's No. 1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have more than 20 years of experience in wheel manufacturing.

We have mature technology in the research and development and production of steel rims. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. Our rims are not only used in a variety of vehicles, but also the original rim suppliers of Volvo, Caterpillar, Liebherr, John Deere and other well-known brands in China.

The steel rims produced by our company have the following characteristics and advantages:

1. High load-bearing capacity: The steel used in our steel rims is of high strength and can withstand heavy weight and strong impact, which is particularly suitable for heavy machinery, mining transportation vehicles and construction machinery.

2. Durability: Due to the use of high-quality steel in production and special treatment (such as heat treatment or anti-corrosion coating), steel rims have high wear resistance and corrosion resistance and can be used for a long time in harsh environments.

3. Effectively reduce costs and improve use efficiency: Compared with materials such as aluminum alloys, steel rims have a lower manufacturing cost, which makes them more common in some large-scale heavy vehicles. It is an ideal choice for cost-sensitive projects and applications, especially for medium-sized construction machinery and mining transportation vehicles.

4. Improve impact resistance: The elasticity and toughness of steel enable the steel rim to effectively resist the impact from uneven ground, stones, potholes, etc., reducing the risk of damage.

We are widely involved in engineering vehicle rims, mining vehicle rims, forklift rims, industrial rims, agricultural rims and other rim accessories and tires.

The 13.00-25/2.5 steel rims we provide for cat R1600 underground mining vehicles have high load-bearing capacity, high durability, improved impact resistance, and improved work efficiency during use, meeting the efficiency, stability and safety required by underground vehicles when working in complex underground environments.

What are the advantages of using 13.00-25/2.5 rims for cat R1600 underground mining vehicles?

The CAT R1600 underground mining vehicle uses the 13.00-25/2.5 rims provided by our company, which has some obvious advantages in work, especially in terms of stability, durability and traction in underground mining environments. Choosing the right rims can improve the efficiency and safety of the vehicle, especially in heavy load operations and complex terrain.

1. Using 13.00-25/2.5 rims can improve load capacity and traction:

The tire size of 13.00-25 means that the tire diameter used by the vehicle is 13.00 inches, the width of the rim is 25 inches, and 2.5 represents the width of the rim (usually in inches). This size of rims, combined with large tires, gives the vehicle better load capacity and traction.

In underground mines, especially in rugged underground passages or heavy object handling operations, the vehicle needs to have sufficient traction to ensure smooth driving. Wider rims can better support larger tires and provide stronger traction, especially when working in slippery or muddy environments, which can prevent tires from slipping.

2. Improve stability and durability:

The width of the rim means a larger contact area, which can disperse the weight of the vehicle and thus improve the ground contact stability. Our company specially developed a 2.5-inch wide rim for cat R1600, which is critical for carrying heavy objects and maintaining vehicle balance in underground operations.

In underground mines, especially in high-load operating environments, the durability of the rim is particularly important. The 13.00-25/2.5 rim provides enhanced impact resistance and wear resistance, and can cope with high impact loads and complex terrain in mining environments.

3. Improve passability:

The working environment of underground mines usually has narrow tunnels and rugged ground. The combination of wide rims and tires can increase the vehicle's ground contact area and reduce the pressure per unit area. This can effectively reduce the risk of vehicles getting stuck in soft or muddy underground environments and improve the vehicle's passability.

Using tires with large diameters and wide rims can provide better support and adaptability in uneven underground environments, and maintain good driving stability even in difficult ground conditions.

4. Improve work efficiency:

Large tires with 13.00-25/2.5 rim configurations can support larger bucket capacity, thereby improving loading capacity. This is very important for loading and transportation operations in underground mines, because large-capacity tires can load more ore or waste, reduce the number of transportation times, and thus improve overall work efficiency.

Larger tires and rims mean that the vehicle's driving speed and operating cycle can be optimized, especially when transporting long distances or unloading quickly, which can reduce operating time.

5. Improve comfort and safety:

Because the wider rim and tire system can better disperse weight and impact, the driver can enjoy a smoother driving experience. This has a significant effect on improving work efficiency and reducing driver fatigue.

6. Adapt to high-load operations: Underground mining vehicles often need to face heavy-load operations during operation, especially when transporting large amounts of ore and waste. At this time, our 13.00-25/2.5 rims can withstand higher loads, thereby ensuring that the vehicle can still operate stably under high-intensity working conditions, and it is not easy to cause tire damage or excessive wear. The combination of 13.00-25/2.5 rims used in CAT R1600 underground mining vehicles helps to improve its load capacity, traction, stability and durability in underground mining operations. This size of rim and tire system can effectively adapt to the rugged terrain, slippery surfaces and high-load operations in underground operating environments, improve the operating efficiency and safety of the vehicle, and reduce the risk of failure in complex underground environments. These advantages enable CAT R1600 to operate efficiently and stably in the harsh environment of underground mines.

Our company can also produce a variety of rims of other sizes in other fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Jan-13-2025