What Is An Excavator In Mining?

An excavator in mining is a heavy mechanical equipment used in mining operations, which is responsible for excavating ore, stripping overburden, loading materials, etc. Mining excavators are widely used in open-pit mines and underground mines because of their large size, high power and high efficiency.

According to the working environment, they can be divided into open-pit mining excavators and underground mining excavators.

Open-pit mining excavators are used for open-pit mining operations, are larger in size, and are commonly found in coal mines, iron mines, gold mines, etc.

Underground mining excavators are designed for narrow tunnels, have a low body, are equipped with explosion-proof devices, and are suitable for underground mines.

According to the operation mode, they can be divided into hydraulic excavators, electric shovel excavators, bucket wheel excavators and grab excavators.

Hydraulic excavators drive the boom, bucket and crawler through the hydraulic system, with high flexibility and suitable for various working conditions in mines.

Electric shovel excavators are driven by electricity and are suitable for high-intensity operations in large-scale open-pit mines. They are usually used for stripping and loading.

Bucket wheel excavators continuously dig through rotating bucket wheels and are suitable for large-scale earthwork or soft rock stripping.

Grab excavators are used for handling bulk materials, usually at docks or ore transfer stations.

We have mature technology in the research and development and production of mining vehicle rims, which are widely involved in mining vehicles such as mining dump trucks, rigid dump trucks, underground mining vehicles, wheel loaders, graders, and mining trailers.

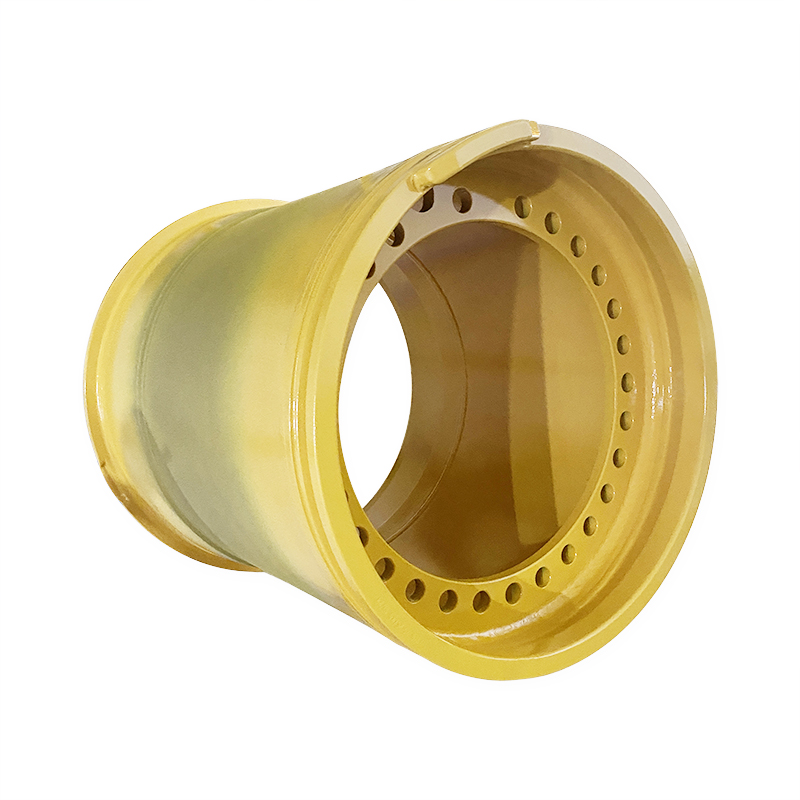

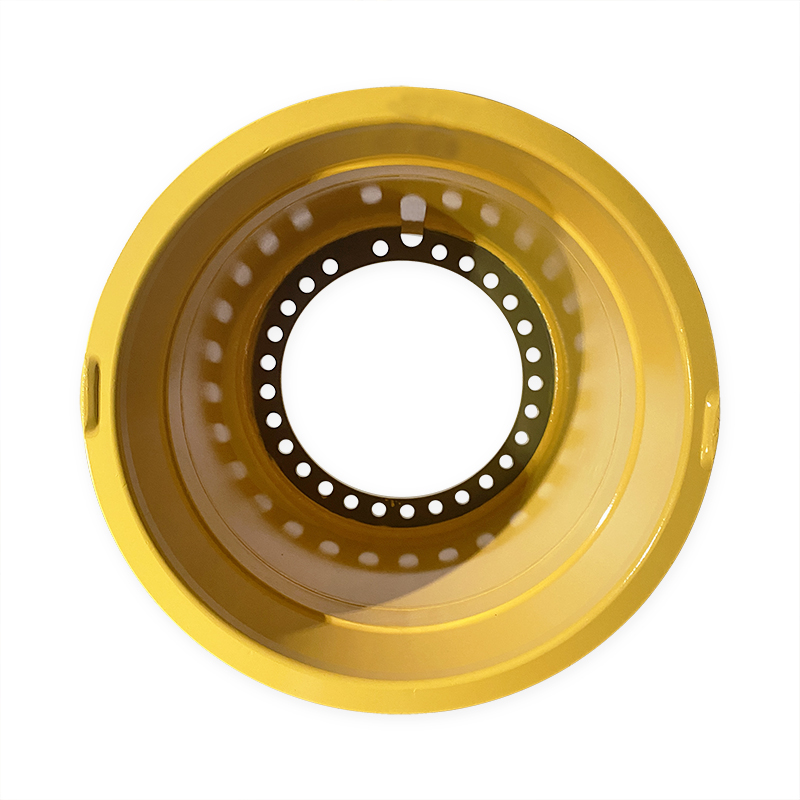

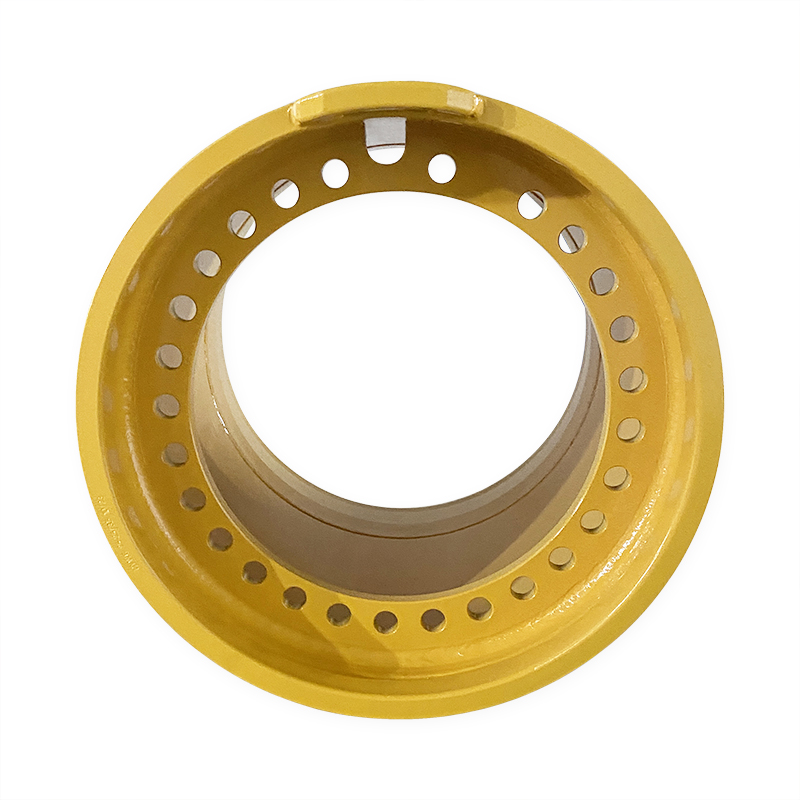

The 25.00-25/3.5 rims we provided for the Komatsu WA500-6 wheel loader have been unanimously recognized by customers during use.

Komatsu is a world-leading manufacturer of construction machinery and mining equipment, known for its high quality, high performance and technological innovation. Its products are widely used in construction, mining, forestry, agriculture, logistics and industry. Komatsu has become a benchmark enterprise in the field of construction machinery and mining equipment with its excellent product quality, global service network and leading technological innovation. Whether on construction sites or in mines, Komatsu equipment is known for its high efficiency, durability and intelligence, and is the preferred brand for industry users. Komatsu has extremely high requirements for product quality. Our rim-equipped wheel loaders are suitable for a variety of uses, from construction sites to mining.

The 25.00-25/3.5 rim is a rim specification suitable for heavy-duty engineering machinery, usually used for mining equipment, large loaders and other vehicles that need to carry high loads.

25.00-25: indicates the standard size of the tire, suitable for tires with a diameter of 25 inches and a width of 25 inches.

3.5: indicates the flange width of the rim (in inches), providing support that matches the tire bead.

Made of high-strength steel, this rim can withstand heavy loads and high impact forces and is suitable for harsh working conditions. The 3.5-inch wide flange design matches large tires and enhances the traction and stability of the vehicle. The surface is treated with a special coating with good corrosion resistance, suitable for slippery and dusty environments. The optimization of the rim structure reduces sliding and wear between the tire and the rim, reducing the risk of tire blowouts.

Since the Komatsu WA500-6 wheel loader will be transported in harsh working conditions such as mining areas and construction sites, the vehicle needs high load-bearing capacity and better traction, so it is necessary to use the 25.00-25/3.5 large-size rims designed by our company for heavy equipment

What Are The Advantages Of The Komatsu Wa500-6 Wheel Loader?

The Komatsu WA500-6 wheel loader is a high-performance and durable construction machinery equipment. With its technical advantages and efficient design, it is highly favored in mines, quarries, ports and other heavy-duty applications. The following are its main advantages:

1. It has strong power, equipped with a Komatsu SAA6D140E-5 engine, providing an output of 357 horsepower to meet the needs of high-intensity operations. Fuel economy: It adopts electronic fuel injection technology and an optimized combustion system to reduce fuel consumption, meet Tier 3 emission standards, and reduce environmental pollution.

2. Excellent operating efficiency, efficient hydraulic system: The closed-center load sensing system (CLSS) provides smooth operation and fast work cycle time, significantly improving productivity. Equipped with a large-capacity bucket: The 4.5-6.0 cubic meter bucket adapts to a variety of materials, reduces loading time, and improves handling efficiency.

3. The spacious cab is ergonomically designed, with a wide field of vision and low operator fatigue. Shock absorption and noise reduction design: The cab shock absorption system and sound insulation materials provide a quiet and comfortable working environment. Easy to operate, equipped with an adjustable seat and a multi-function control panel, which is convenient for operators to adapt quickly.

4. Reinforced structural design: The frame and boom are made of high-strength materials to adapt to harsh working environments. Wear-resistant parts: The bucket edge and other vulnerable parts are made of wear-resistant alloy materials to extend the service life. Reliable cooling system: The optimized cooling system ensures the stability of the equipment in high temperature and long-term operation.

5. Support KOMTRAX remote monitoring system: Provides real-time equipment status, fuel consumption, maintenance prompts and other information to facilitate users to manage equipment. Maintenance convenience: The intelligent system reminds users to perform maintenance on time to reduce unplanned downtime.

6. Adapt to a variety of working conditions: From heavy-duty operations in mines to fast loading and unloading at ports, it performs well. Flexible configuration: Buckets of different capacities can be selected according to needs to adapt to the diversity of material types.

7. Low operating cost: High fuel efficiency and long service life reduce the overall operating cost of the equipment. Reduce downtime: Reliable structural design and intelligent monitoring system reduce equipment failure rate and ensure work continuity.

The advantages of Komatsu WA500-6 wheel loader are reflected in strong power, excellent fuel economy, excellent durability and comfortable operating experience. At the same time, intelligent technology makes equipment management more efficient. It is an ideal choice for improving efficiency and reducing costs in heavy engineering and logistics scenarios.

We are China's No. 1 off-road wheel design and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have mature technology in the research and development and production of mining vehicle rims. We have extensive involvement in mining vehicles such as mining dump trucks, rigid dump trucks, underground mining vehicles, wheel loaders, graders, mining trailers, etc. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. You can send me the rim size you need, tell me your needs and troubles, and we will have a professional technical team to help you answer and realize your ideas.

We not only produce mining vehicle rims, but also widely involved in engineering machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, etc.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Dec-16-2024