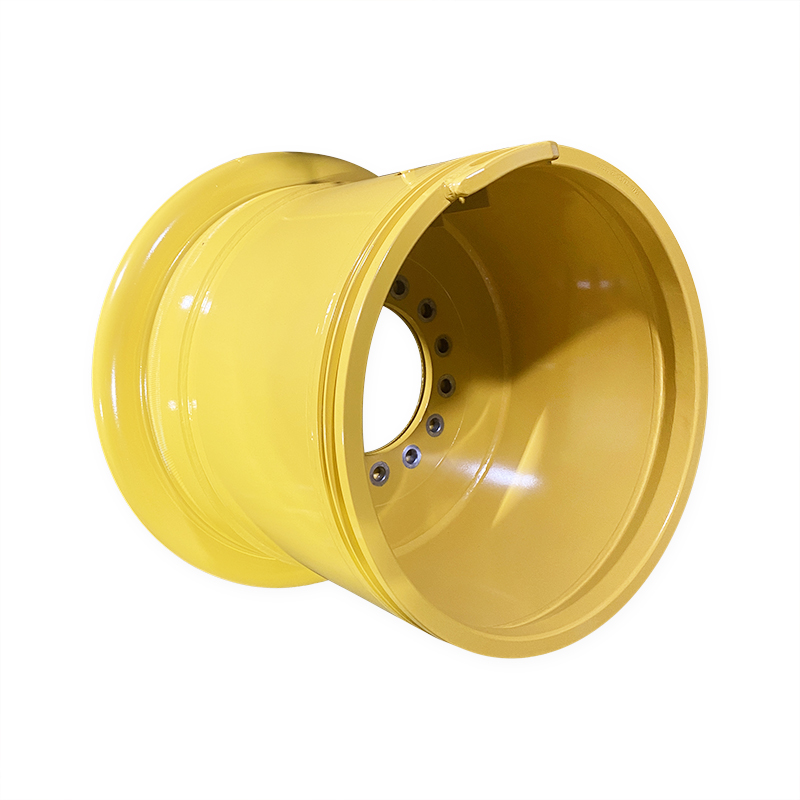

Rims of construction machinery (such as those used by loaders, excavators, graders, etc.) are durable and designed to withstand heavy loads and harsh working environments. Usually, they are made of steel and specially treated to improve impact resistance and corrosion resistance. The following are the main structural parts and features of construction machinery rims:

1. Rim

The rim is the edge of the tire mounted on the rim and contacts the tire's bead. Its main function is to fix the tire and prevent it from sliding or shifting when it is under high load or high speed.

The rim of construction machinery is usually thickened to cope with the high load requirements of the tire, and at the same time has high impact resistance and can adapt to heavy-duty operations in harsh environments.

2. Rim seat

The rim seat is located on the inside of the rim and fits tightly with the tire's bead to ensure the airtightness and stability of the tire. The rim seat is designed to be smooth to ensure that the tire can evenly distribute the force on the rim.

In order to enhance safety, the rim seat of construction machinery is often precision-processed to ensure that the tire is not easy to slip under high pressure.

3. Rim base

The rim base is the main load-bearing structure of the rim and the supporting foundation of the tire. The thickness of the base and the strength of the material determine the overall load-bearing capacity and durability of the rim.

The rim base of construction machinery is usually made of high-strength steel and heat-treated to improve its load-bearing capacity and impact resistance.

4. Retaining ring and locking ring

Some construction machinery rims, especially split rims, are equipped with retaining rings and locking rings. The retaining ring is installed on the outside of the rim to fix the tire, and the locking ring is used to fix the retaining ring position to ensure that the tire is firm.

This design facilitates the installation and removal of the tire and is very practical in scenarios where tires need to be replaced quickly. The retaining ring and locking ring are usually also reinforced and have high pressure and impact resistance.

5. Valve hole

The rim is designed with a valve hole for installing a valve for tire inflation. The design of the valve hole position should avoid conflict with the supporting structure to ensure safety and convenience during inflation.

The valve holes of the rims of construction machinery are usually reinforced to prevent cracks caused by pressure changes during inflation and deflation.

6. Spokes

In one-piece rims, the rims are usually equipped with a spoke structure to connect the rim to the axle. The spoke part usually has bolt holes for bolting to ensure that the rim is firmly mounted on the axle.

The spoke part is designed to be sturdy and can withstand pressure from different directions and maintain the stability of the rim.

7. Coating and anti-corrosion treatment

The rims of construction machinery are often subjected to surface coating treatment after manufacturing, such as spraying anti-rust paint or electroplating, to enhance their corrosion resistance.

This anti-corrosion treatment is particularly suitable for working in high humidity, mud or acid-base environments, extending the service life of the rims.

Structural Classification Of Rims

The rims of construction machinery are generally divided into the following types, designed according to different needs:

Single-piece rims: one-piece design, suitable for light or medium-sized construction machinery, simple structure but strong load-bearing capacity.

Multi-piece rim: It is composed of multiple parts, including retaining rings and locking rings, which are easy to disassemble and assemble, and suitable for large construction machinery.

Split rim: It is used for large and heavy equipment, which is convenient for replacing tire rims and improving working efficiency.

The rim construction of construction machinery emphasizes high strength, impact resistance and corrosion resistance. Through strong materials and scientific design, it can meet the needs of heavy equipment in various harsh working conditions. This rim ensures that the equipment maintains stable and reliable performance in complex working environments.

HYWG is China's first off-road wheel designer and manufacturer, and is also a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have more than 20 years of wheel manufacturing experience in construction machinery, mining vehicle rims, forklift rims, industrial rims, agricultural rims and other rim accessories and tires.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system, providing timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We are the original rim supplier in China for Volvo, Caterpillar, Liebherr, John Deere and other well-known brands.

We manufacture and produce rims and accessories of various sizes for construction machinery, which have won unanimous recognition from customers. Among them, rims with a size of 19.50-25/2.5 are widely used in wheel loaders.

What Are The Models Of Wheel Loaders That Use 19.50-25/2.5 Rims?

Wheel loaders that use 19.50-25/2.5 rims are usually some medium to large construction machinery, especially suitable for various heavy load and complex working conditions. This rim specification (19.50-25/2.5) means that the tire width is 19.5 inches, the rim diameter is 25 inches, and the rim width is 2.5 inches. This specification of rims is usually used with most wheel loaders with high load capacity.

The following are some common models of wheel loaders that use 19.50-25/2.5 rim specifications:

1. Caterpillar

CAT 980M: This wheel loader is widely used in construction, mining and other heavy industrial operations. It is equipped with a rim specification of 19.50-25/2.5, has a high load capacity, and is suitable for complex working environments.

CAT 966M: Another loader with 19.50-25 rims, suitable for working conditions that require high traction and high durability.

2. Komatsu

Komatsu WA380-8: Designed for a variety of construction and mining applications, this loader is equipped with 19.50-25/2.5 rims, which can maintain excellent stability and operating efficiency in various ground conditions.

3. Doosan

Doosan DL420-7: This medium-sized wheel loader from Doosan uses 19.50-25 rims to provide high traction and durability in heavy earthmoving operations.

4. Hyundai

Hyundai HL970: This loader from Hyundai also uses 19.50-25/2.5 rims, which is suitable for heavy-duty operations and provides excellent handling performance and stability.

5. Liugong

Liugong CLG856H: This loader is widely used on construction sites and uses 19.50-25 rims, which can provide good load capacity and stability in complex working conditions.

6. XGMA

XGMA XG955: This loader from XGMA is suitable for 19.50-25 rims and is suitable for earthmoving, mining and other fields. It has the characteristics of high load and durability.

These wheel loaders use 19.50-25/2.5 rims, mainly to adapt to high load and high-intensity working environments. When purchasing a wheel loader, it is very important to ensure that the rim and tire specifications match, which helps to improve work efficiency, extend equipment life and ensure safety.

We can also produce a variety of rim components: including lock rings, side rings, bead seats, drive keys and side flanges, suitable for different types of rims, such as 3-PC, 5-PC and 7-PC OTR rims, 2-PC, 3-PC and 4-PC forklift rims. Rim components come in a wide range of sizes, from 8 inches to 63 inches. Rim components are critical to the quality and capacity of the rim. The lock ring needs to have the right elasticity to ensure that it can lock the rim while being easy to install and remove. The bead seat is critical to the performance of the rim, it bears the main load of the rim. The side ring is the component that connects to the tire, it needs to be strong and precise enough to protect the tire.

Here are some examples of the models we offer:

|

Locking ring |

25" |

Side Flange |

25",1.5" |

|

29" |

25",1.7" |

||

|

33" |

Side Ring |

25",2.0" |

|

|

35" |

25",2.5" |

||

|

49" |

25",3.0" |

||

|

Bead Seat |

25",2.0",Small driver |

25",3.5" |

|

|

25",2.0" Big driver |

29",3.0" |

||

|

25",2.5" |

29",3.5" |

||

|

25" x 4.00" (Notched) |

33",2.5" |

||

|

25",3.0" |

33",3.5" |

||

|

25",3.5" |

33",4.0" |

||

|

29" |

35",3.0" |

||

|

33",2.5" |

35",3.5" |

||

|

35"/3.0" |

49",4.0" |

||

|

35"/3.5" |

Board driver kit |

All sizes |

|

|

39"/3.0" |

|||

|

49"/4.0" |

We are widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Nov-20-2024