What Is The Purpose Of The Rim?

The rim is the supporting structure for the tire installation, usually forming a wheel together with the wheel hub. Its main function is to support the tire, keep its shape, and help the vehicle to stably transmit power and braking force when driving.

Mainly used for:

1. Support tires: The rim provides a stable installation base for the tire, ensures that the tire maintains the correct shape, and can evenly bear the load.

Under high load and high impact conditions, the rim needs to have sufficient strength and rigidity to prevent deformation or damage.

2. Transmit driving force and braking force: The rim contacts the ground through the tire, transmits the driving force of the engine to the ground, and enables the loader to travel and work. When braking, the rim also participates in the transmission of braking force to ensure that the vehicle decelerates or stops stably.

3. Affects tire sealing and air tightness: Pneumatic tires rely on the airtight design of the rim to prevent air leakage, especially tubeless tires. The air tightness of the rim directly affects the service life and safety of the tire.

4. Affect vehicle stability and handling: Parameters such as rim width, diameter, offset, etc. will affect the tire's contact area, grip, and balance of the vehicle. Rims of different widths will affect the deformation of the tire, which in turn affects the vehicle's driving performance.

5. Adapt to the needs of different working conditions: In harsh environments such as mines and quarries, rims are usually thickened to improve impact resistance and durability. In special working conditions such as ports and garbage disposal, rims may use anti-corrosion coatings or special materials to extend service life.

6. Convenient tire disassembly and replacement: The design of the rim takes into account the convenience of loading and unloading, especially large loaders, which may be equipped with split rims or lock ring rims to facilitate tire replacement and improve maintenance efficiency.

Simply put, the rim is a ring-shaped metal part on the wheel that supports and fixes the tire. It is not only related to the driving safety of the vehicle, but also affects the vehicle's handling and comfort.

HYWG is China's No. 1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

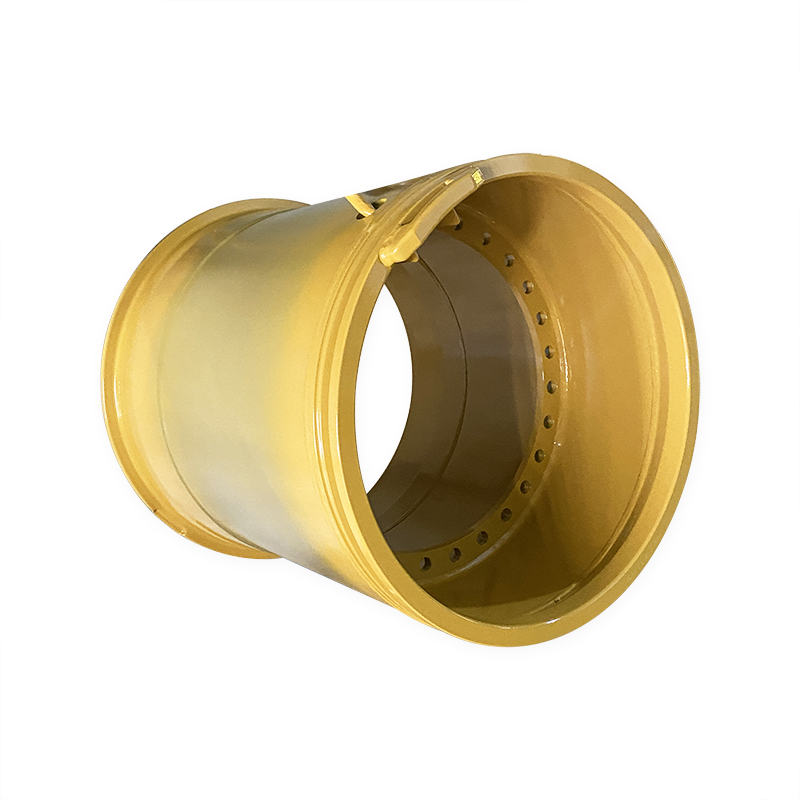

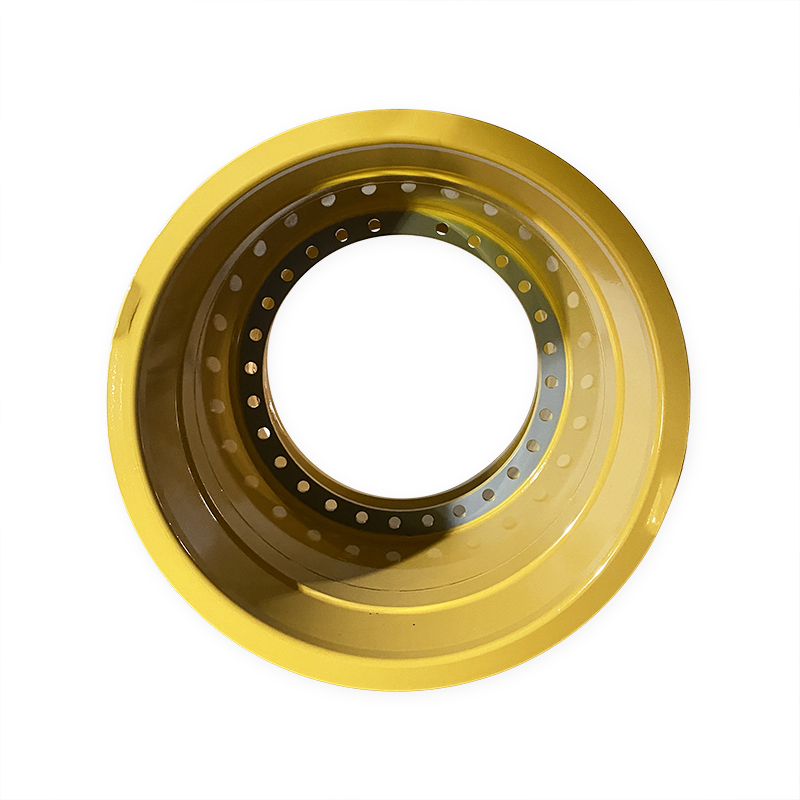

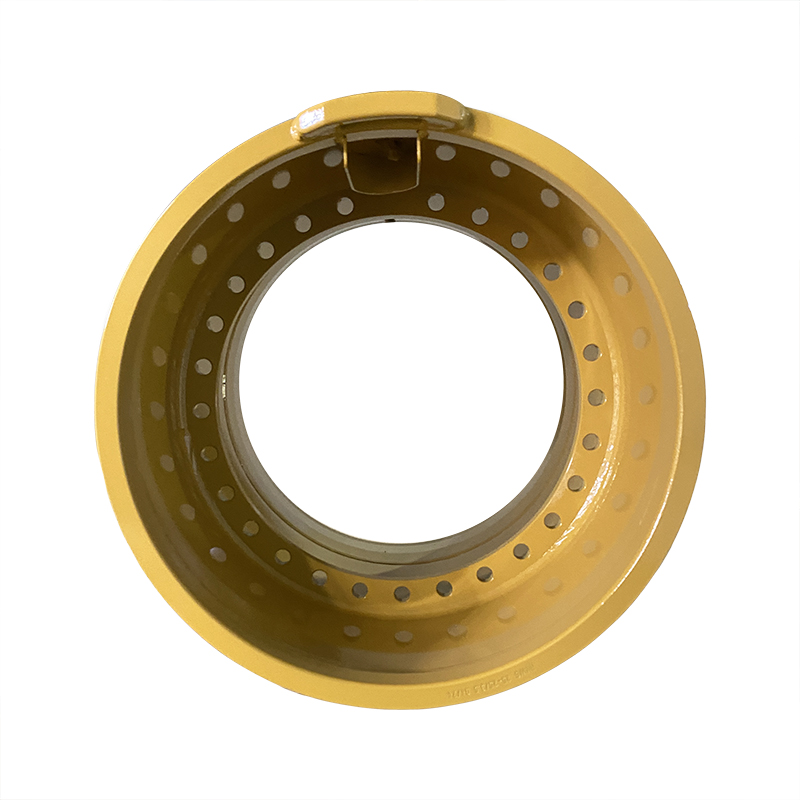

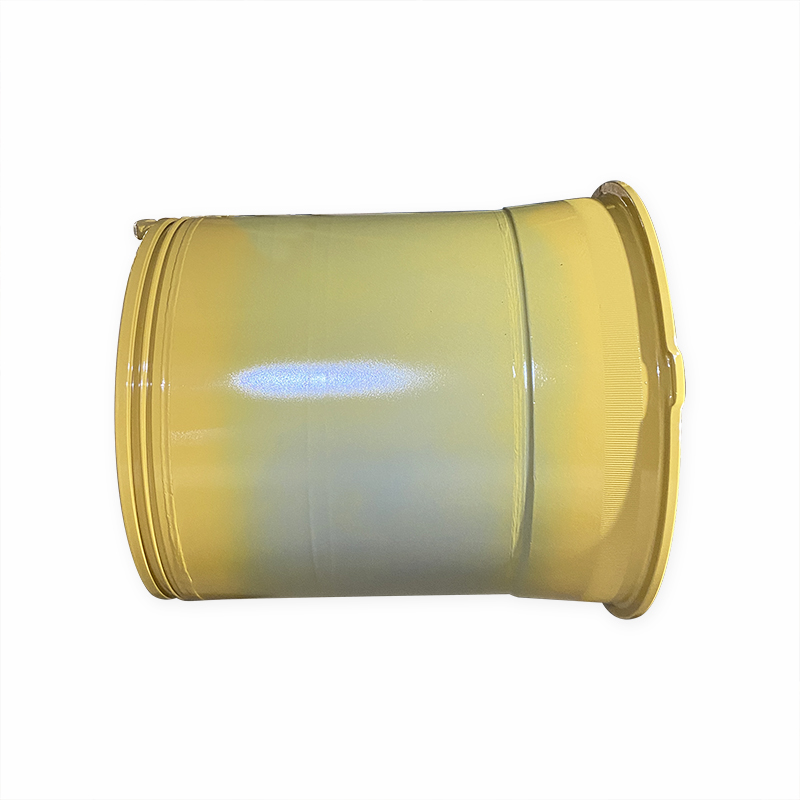

We have very rich experience in the manufacture of engineering vehicle rims. We have produced rims with a size of 25.00-25/3.5 for Caterpillar articulated truck cat 740.

25.00-25/3.5 rims are off-road (OTR) rims, which are widely used in mining machinery and construction machinery, such as large loaders, mining dump trucks, etc. Such rims are mainly suitable for 25-inch tires.

We designed a 5-piece rim structure for cat 740. This design is easy to disassemble and assemble, and is suitable for high-load mining and construction machinery. It uses high-strength steel, can withstand extreme working conditions, is wear-resistant and corrosion-resistant, and is suitable for harsh environments.

What Are The Advantages Of Cat740?

Caterpillar (CAT) 740 series articulated trucks, as heavy-duty transport equipment, perform well in harsh environments such as mines and construction sites. Its advantages are mainly reflected in the following aspects:

Powerful power and performance:

The CAT 740 series is equipped with a high-performance Caterpillar engine, providing powerful power output, and can easily cope with various complex terrains and heavy-load transportation tasks.

The advanced transmission system and drive axle design ensure efficient power transmission and improve transportation efficiency. Excellent reliability and durability:

Caterpillar products are well-known for their durability. The CAT 740 series uses high-strength materials and exquisite manufacturing processes to ensure that the equipment can operate stably for a long time under harsh working conditions.

Key components have been rigorously tested and verified, with excellent reliability and durability, reducing maintenance costs and downtime. Excellent handling and comfort:

Advanced suspension system and steering system provide excellent handling and driving stability, reducing driver fatigue.

The ergonomic cab design provides a comfortable working environment and improves the driver's work efficiency. Efficient fuel economy:

Caterpillar engines use advanced fuel management technology to optimize fuel consumption and reduce operating costs.

Intelligent power management system automatically adjusts engine output according to working conditions to improve fuel utilization. Advanced technology and intelligence:

Equipped with advanced monitoring systems and diagnostic tools, real-time monitoring of equipment operating status, convenient fault diagnosis and maintenance.

Various intelligent systems can be optionally installed, such as load weighing system, terrain monitoring system, etc., to improve transportation efficiency and safety. Environmental adaptability:

CAT740 series, it meets relevant emission standards.

And when designed, considering the operation in various harsh environments, so its environmental adaptability is very strong.

In short, CAT 740 series articulated trucks have become an ideal choice in the field of heavy transportation with their powerful power, excellent reliability, excellent handling and efficient fuel economy.

We not only produce engineering machinery rims, but also have a wide range of mining vehicle rims, forklift rims, industrial rims, agricultural rims and other rim accessories and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Mar-12-2025