The most durable rims depend on the environment and material properties of the use. The following rim types show different durability in different situations:

1. Steel rims

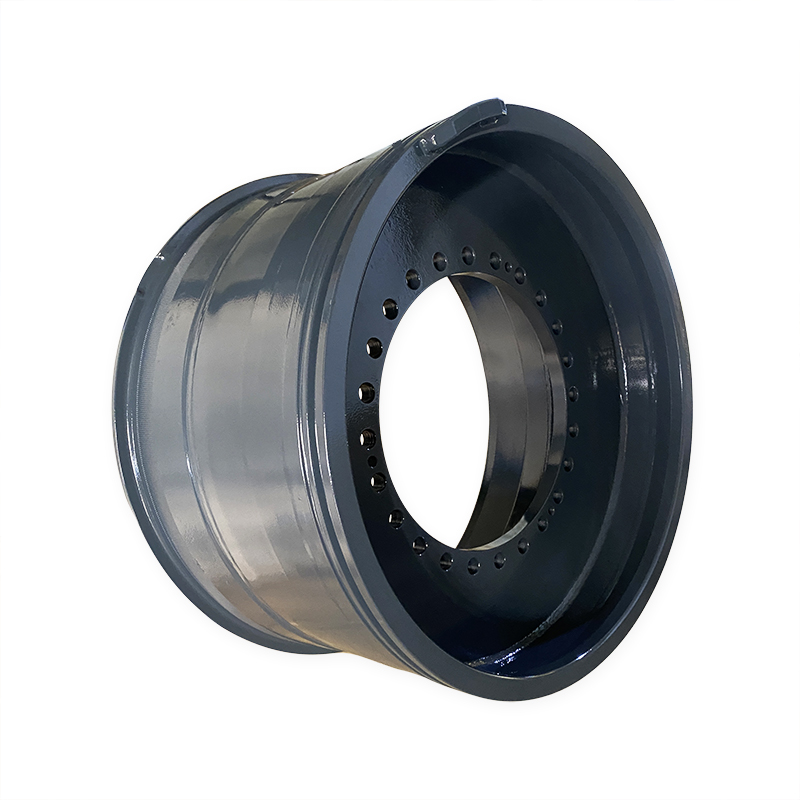

Durability: Steel rims are one of the most durable types of rims, especially when subjected to extreme impact or heavy loads. They are highly impact-resistant and can withstand impacts without easily cracking or breaking.

Applicable scenarios: Suitable for harsh environments, off-road vehicles, heavy trucks, and construction machinery. Especially suitable for places with harsh conditions such as mines and construction sites.

Repairability: If steel rims are bent, they can usually be corrected with simple repair tools without replacement.

Summary: Steel rims are the most durable choice, especially suitable for heavy loads and harsh road conditions due to their high strength and durability.

2. Forged aluminum alloy rims

Durability: Forged aluminum alloy rims have higher strength and toughness than ordinary cast aluminum alloy rims. The forging process makes them denser, more impact-resistant, and lighter.

Applicable scenarios: Suitable for high-performance vehicles, SUVs, and applications that require lightweighting. They perform well in urban driving and highway conditions.

Repairability: Once a forged aluminum rim is damaged, it is difficult to repair and usually needs to be replaced.

Summary: Forged aluminum alloy rims achieve a good balance between strength and lightness and are more durable aluminum rims.

3. Magnesium alloy rims

Durability: Magnesium alloy rims are very light, but they are not as strong and impact-resistant as steel or forged aluminum alloy rims. They are suitable for occasions where performance rather than durability is pursued.

Applicable scenarios: Mainly used in racing and high-performance sports cars, not suitable for daily driving or harsh environments.

Repairability: Magnesium alloy rims are relatively fragile, and once damaged, repair is more complicated and usually needs to be replaced.

Summary: Although light, magnesium alloy rims are not as durable as steel or forged aluminum, and are suitable for racing or sports occasions with high lightweight requirements.

4. Carbon fiber rims

Durability: Carbon fiber rims are extremely light, but they have poor toughness and are easily damaged by impact, which is suitable for applications that require extreme lightness and high performance.

Applicable scenarios: Top racing or ultra-high-performance sports cars, usually used on the track.

Repairability: Once damaged, carbon fiber rims are almost impossible to repair and usually need to be completely replaced.

Summary: Carbon fiber rims excel in extreme lightweighting, but are not suitable for environments that require high durability.

Therefore, steel rims are the most durable and are particularly suitable for heavy-duty working environments (such as mines, construction sites, etc.) that require high impact resistance and load-bearing capacity.

Forged aluminum alloy rims are more durable and have superior performance. They have a good balance between durability and lightweight and are suitable for high-performance vehicles and daily driving.

If durability is the primary consideration, especially in harsh environments, steel rims are the best choice. If both performance and durability are required, forged aluminum alloy rims are the ideal choice.

Choosing the right rims can not only enhance the working efficiency of the vehicle, but also extend the service life of the tires and equipment. For example, the 17.00-35/3.5 size rims used by large rigid dump trucks for mining vehicles

Our technology is very mature in the production of rigid dump truck rims. The following are some of the sizes we can produce.

|

Rigid Dump truck |

15.00-35 |

Rigid Dump truck |

29.00-57 |

|

Rigid Dump truck |

17.00-35 |

Rigid Dump truck |

32.00-57 |

|

Rigid Dump truck |

19.50-49 |

Rigid Dump truck |

41.00-63 |

|

Rigid Dump truck |

24.00-51 |

Rigid Dump truck |

44.00-63 |

|

Rigid Dump truck |

40.00-51 |

Since the mining environment is usually rugged and includes complex terrain such as potholes, rocks, mud, steep slopes, etc., choosing the right large-size rims combined with the right tires can increase the ground clearance of the vehicle, enhance the vehicle's passability, help them smoothly cross obstacles or uneven ground, and improve stability. In addition, mining vehicles (such as large mining trucks and loaders) usually need to carry very heavy loads, often tons or even hundreds of tons of ore or cargo. Large steel rims can be equipped with larger loads, provide a larger load contact area and carrying capacity, thereby evenly distributing heavy loads and reducing tire damage.

How to choose the right steel rim?

Choosing the right steel rim requires a comprehensive consideration of the vehicle type, use environment and specific needs. The following are several key selection criteria and steps:

1. Understand the type and purpose of the vehicle

Different vehicles and application scenarios have different requirements for rims. Mining vehicles, construction equipment, heavy trucks and off-road vehicles usually require sturdy and durable steel rims, while passenger cars or light vehicles may consider the weight and appearance of the rims more.

Heavy machinery and mining vehicles: require thicker, stronger steel rims that can withstand high loads and extreme working conditions.

Ordinary trucks or off-road vehicles: You may need a rim that strikes a balance between strength and weight.

2. Choose the right size according to the tire specifications

Rim size: Make sure the size (diameter and width) of the rim matches the tire. The appropriate rim diameter is usually marked on the sidewall of the tire, such as "17", indicating that a 17-inch rim is required. The width of the tire and rim also need to match to ensure driving safety and performance.

Width selection: The width of the rim should usually be slightly smaller than the width of the tire to ensure that the tire can be firmly assembled on the rim while maintaining proper air pressure and stability.

3. Check the load capacity of the rim

Load rating: The load capacity of steel rims is very important, especially for heavy vehicles. When selecting, make sure that the load capacity of the rim can withstand the total weight of the vehicle and its maximum weight when fully loaded. The load capacity of the rim can usually be obtained from the manufacturer's specifications.

Load requirements: If the vehicle needs to frequently transport heavy objects or travel on rough terrain, it is necessary to choose steel rims with high load ratings to avoid premature wear or damage.

4. Consider the offset of the rim

Offset (ET value): Offset refers to the distance between the rim mounting surface and the rim centerline. The correct offset ensures that the tire works well with the vehicle suspension system. Too much positive offset may cause the tire to shrink inward, affecting steering and suspension, while too much negative offset may cause the tire to protrude too much, increasing the load on the suspension components.

Vehicle specification requirements: Choose the right rim according to the recommended offset parameters provided by the vehicle manufacturer to avoid handling or tire wear problems.

5. Corrosion resistance and coating treatment

Steel rims are prone to rust when exposed to outdoor environments for a long time, so it is important to choose rims with good anti-corrosion coatings. Mining and construction machinery vehicles require a higher level of corrosion protection.

Coating selection: Galvanizing, powder coating or other anti-rust coatings can greatly improve the corrosion resistance of the rim, especially in wet, muddy and dusty environments.

6. Pay attention to the manufacturing process and quality of the rims

Manufacturing process: Choose steel rims that are manufactured through high-quality welding and forming processes to ensure their structural strength and durability. Rims with poor craftsmanship may have problems such as loose welding and material defects, which can easily lead to rim damage.

Certification and standards: Make sure the rims meet relevant quality standards and certifications (such as ISO, JIS or SAE), which can ensure the safety and reliability of the rims during the design and manufacturing process.

7. Consider the weight of the rims

Although steel rims are generally heavier than aluminum rims, different steel rims can also vary in weight. For vehicles that need to move frequently, lighter steel rims can reduce vehicle weight, improve fuel efficiency, and improve handling.

8. Pay attention to accessory compatibility

Hub bolt pattern: Make sure the number and arrangement of bolt holes on the rim match the vehicle's hub. The bolt pattern (such as 4×100, 5×114.3) should be consistent with the vehicle's original rims to ensure safe installation.

Center hole size: The center hole of the steel rim should be precisely matched with the vehicle's wheel hub to avoid rim deformation or safety hazards due to looseness.

9. Budget and maintenance costs

Steel rims are generally cheaper than rims made of other materials, but the price will vary depending on the quality and anti-corrosion treatment. Choose high-quality, durable steel rims, although the initial cost may be slightly higher, but the maintenance cost will be lower in long-term use.

When choosing the right steel rim, first make sure that the rim size, load capacity and offset meet the vehicle needs, and have good corrosion protection and manufacturing process. If the vehicle is used for heavy-duty operations or harsh environments, durability and high load-bearing capacity are the priority factors; for ordinary off-road vehicles or trucks, a balance between strength and weight is required.

We are China's number one off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards, and we have more than 20 years of experience in wheel manufacturing. We are widely involved in engineering machinery, mining vehicle rims, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system, providing timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. If you have any troubles and questions that need to be consulted, you can contact us!

The following are the various sizes of rims that our company can produce for different fields:

Engineering machinery sizes: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 13.00-25, 14.00-25, 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Mining sizes: 22.00-25, 24.00-25 , 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-34, 15.00-35, 17.00-35, 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Forklift sizes are: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15, 6.50-15, 7.00 -15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Industrial vehicle sizes are: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5, 9.75x16.5, 16x17, 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28

Agricultural machinery sizes are: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 11x18, W8x18, W9x18, 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x30, DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Our products have world-class quality.

Post time: Oct-29-2024